Reducing Construction Waste with BIM

CHAPTER 1 INTRODUCTION

1.0 Introduction

For many years, the construction industry has suffered from many problems, with waste becoming a rising issue. According to a survey conducted by the Government Statistical Service in the United Kingdom (UK), ‘the construction industry produces over 70 million tonnes of waste, which is equivalent to four times the rate of household waste production’ (Keys et.al, 1998). Waste is a major issue within the construction industry, which is created by the arrival of resources and unpredicted release of work. Research shows that waste can occur at any phase of construction projects; it can arise from the design, construction or operation phase (Faniran and Caban, 1998 and Craven et al., 1994). This project will highlight what types of wastes can be identified in all of the phases of construction and how BIM can reduce the wastes found in the construction process. The construction industry has implemented many lean tools and techniques such as 5s process, value stream mapping, poka yoke, last planner system and increased valuation to tackle this issue. The main objectives of the tools and techniques are to minimise waste, deliver the project on time and within budget. Although there are many lean tools and techniques, this project will focus on the emerging lean tool Building Information Modelling (BIM). The BIM tool assists the construction industry by reducing waste, minimise costs and increase efficiency as well as improving productivity. This has led to BIM becoming an increasingly popular tool, that is forecast to be the future of the construction industry. BIM can enhance the lean outcomes in any project that is on a lean journey (Sacks, et.al, 2010) BIM and lean can minimise inefficiency, waste and the potential for litigation (Chuck Eastman, 2009). Therefore, this addresses the question “how effective the emerging lean tool BIM in the construction process”? and whether the tool helps achieve a leaner construction. Also, there is still uncertainty regarding BIM being a lean tool. This project tends to answer the questions by the results achieved.The title of this project is how effective is the emerging lean tool BIM in the construction process. The project will consist of a literature review which examines the following areas: introduction to lean construction, lean construction tools and techniques, waste in construction, definition and application of BIM, barriers of BIM adaptions, benefits of BIM and successful implementation of BIM case studies. The study includes a methodology section which justifies the research strategy and methods of data collection that were used to complete this project. Also, it will consist of a result and analysis section which presents the results obtained of the project. Lastly, the project will comprise of a discussion and conclusion section which answers the research questions and the objectives of the project. This will be justified through the results obtained from the literature, case studies, interviews and questionnaires. The hypothesis, aim and objectives of the project is shown below. A structure of the thesis has also been provided to summarise the main areas of the project.

1.1 Hypothesis: -

Implementing the emerging lean tool BIM can lean have significant impact on reducing waste and shortening duration of projects during the construction process.

1.2 Aim: -

The aim of this research project is to evaluate how effective the emerging lean tool BIM is in the construction process.

Take a deeper dive into Construction Company Case Study with our additional resources.

1.3 Objectives: -

The following objectives will be completed to determine how effective is the lean construction tool BIM is in the construction process.

To carry out a literature review to determine how the lean tool BIM can minimise the types of waste identified in the construction process.

Assess how BIM achieves lean principles by reducing project costs, minimising waste, shortening the project duration in the construction process.

To explore the perspectives of different individuals who are working and studying within the construction industry by undertaking interviews and questionnaires.

To Demonstrate the benefits of BIM by providing three case studies of successful BIM construction projects.

1.4 Structure of the Thesis

The structure of the thesis summarises the fundamental areas of the research project. This is provided to assist the reader to follow. The main chapters of the report are shown below and include detail of what to expect in each chapter.

Continue your journey with our comprehensive guide to Innovation in AEC.

Chapter 1 Introduction

This chapter introduces the issues the construction industry has faced over the years and how the construction industry has tried to tackle this problem. This chapter includes a hypothesis, aim and objectives of this project.

Chapter 2 Literature Review

This chapter reviews literature relating to the effectiveness of the emerging lean tool BIM in the construction process. The main headings of the literature review have been divided into the following categories: Introduction to Lean Construction, Lean Construction Tools and Techniques, Waste in Construction, Introduction to BIM, Development of BIM, Application of BIM, The barriers of BIM adaptation, Benefits and drawbacks of BIM and the Successful implementation of BIM case studies.

Chapter 3 Research Methodology

This chapter clarifies the research strategy used for this which is the qualitative research strategy. It will provide a justification on why the phenomenology and case study approach was chosen from the five main types of qualitative approaches. Also, it will discuss the methods used for data collection which are primary and secondary sources.

Chapter 4 Results and Analysis

This chapter will include the results obtained from the literature review, case studies, interviews and questionnaires.

Chapter 5 Discussion and Conclusion

In this chapter, it will discuss the results and analysis section. This section will examine the results and answer the research questions of the project.

Chapter 6 Recommendations

This section consists of recommendations for successful future implementation.

CHAPTER TWO - LITERATURE REVIEW

2.0 Introduction to Literature review

Continue your exploration of Decoupling Point in Supply Chains with our related content.

The purpose of this section is to review the literature related to the study which is to the effectiveness of the emerging lean tool BIM in the construction process. The main headings of the literature review have been divided into the following categories: Introduction to Lean Construction, Lean Construction Tools and Techniques, Waste in Construction, Introduction to BIM, Development of BIM, Application of BIM, The barriers of BIM adaptation, Benefits and drawbacks of BIM and the Successful implementation of BIM case studies.

2.1 Introduction to Lean Construction

Lean construction is defined in many ways, there is no single definition of lean construction according to Alves, (2012) and Jørgensen and Emmitt, (2008). Koskela (2002), Ahmed and Forbes (2011) has defined lean construction as “a way to design production systems to minimise waste of materials, time, and effort in order to generate the maximum possible amount of value for the customer”. It is defined by the Construction Industry Institute (CII) as “the continuous process of eliminating waste, meeting or exceeding all customer requirements, focusing on the entire value stream, and pursuing perfection in the execution of a constructed project” (CII, 2017).Lean construction was introduced to the construction industry by Lauri Koskela in 1992. Lauri Koskela presented the term lean in his report on the Application of the new production philosophy to construction (Jørgensen and Emmitt, 2008; Koskela, 1992). Lean principles were established in the early 1900’s by Henry Ford. When Henry Ford introduced lean principles to the assemble line that transformed car production (Smook et al, 1996), Common et al, 2000), and Mossman, 2009). The concept of lean construction comes from lean production. Lean production principles were developed within the automotive industry in the 1950’s by Toyota led by engineer Taiichi Ohno (Womack et al., 1990). Taiichi Ohno was a Japanese engineer who began experimenting with different types of management systems (Lindholm, 2014; Salihi, 2013). The purpose of the experiments was to eliminate waste and increase value by implementing reduced set up times, semi-autonomous machines, small lot production, improved co-operation with suppliers (Monden, 1983, Ohno, 1988, Shingo, 1984). Koskela (1992) then presented the transformation-flow-value model of production known as the TFV theory of construction. The theory is based upon two types of activities used to eliminate waste: Conversion and Flow. The traditional thinking of construction focusses on conversion activities and ignores flow and value considerations. The TFV theory of construction may result in enhanced performance. (Garnett et al., 1998; Senaratne & Wijesiri, 2008). Womack and Jones (1996) suggests that the five key principles of lean production consist of: identifying the value, map the value stream, make the value flow without interruptions, let the customer pull value through the producer and seek perfection through continuous improvement. This theoretical approach is called “Lean Thinking” (Terry & Smith, 2011). Howell and Glenn Ballard founded the Last Planner System (LPS)and the Lean Project Delivery System (LPDS) in 1997 (Ballard, 2000). The last planner system is a lean construction tool that was developed to adapt lean principles. Koskela inspired authors such as Howell and Glenn Ballard to create lean tools like the Last Planner System.

2.2 Lean Construction Tools and Techniques

There are many tools and techniques that can be implemented within construction. However, only a few of the tools and techniques will be discussed. These tools and techniques include; Last Planner System, Increased visualisation, 5S process, Value Stream Mapping, Poka Yoke JIT and BIM. The use of lean tools and techniques within a company can have significant benefits such as cost savings and productivity.

Last planner system (LPS)

According to Ballard (1997) “the aim of the Last Planner System is to improve productivity by elimination barriers to workflow” (Salem et. al, 2005). The LPS technique addresses project variability as well as shapes work flow. The LPS focuses on the planning functions of construction. It uses two key functions such as look ahead plan and percent planned complete. The look ahead plan is used to plan what can be done when constraints are removed, and the percent planned complete monitors the look ahead plan and requires reason for delay (Ansell et al., 2007).

Increased Visualisation

The increased visualisation tool is used to provide key information to the workforce through visual representation such as signage and labels. The aim of increased visualisation is to assist employees to remember elements such as performance target, and workflow (Moser and Dos Santos, 2003).

The 5s Process

According to Kobayashi (1995 and Hirano (1996) the 5s process translated from Japanese to English refers to Sort, Straighten, Shine, Standardise and Sustain. The aim of the 5s process tool is to have five levels of housekeeping in order to remove waste. Additionally, the 5s tool is used to improve productivity and safety by leaving the site clean and tidy (Kobayashi, 1995 and (Hirano, 1996).

Value Stream Mapping

The value stream mapping tool highlights lead time, the activities that tend to add value and the activities that tend not to add value. The value stream mapping tool involves mapping the construction process, then it is documented, and the flow of the process is improved to make it more streamlined (Braglia et al, 2006, Arbulu and Tommeline, 2003).

Poka Yoke

The Poka yoke tool was introduced by Shingo (1986), it is used for quality control and the tool prevents errors from flowing through the process. The Poka Yoke in Japanese means error proofing, it reduces the time to perform a task (Hinckley ,2001)

Just in Time (JIT)

The JIT tool ensures that there are resources available on construction sites at the right time. JIT will deliver what is required and the amount required at the right time. It removes waiting time in construction as well as saving time on projects (Forbs and Ahmed, 2011).

Building Information modelling (BIM)

BIM is a lean tool that can be used for design, construction and operations. It allows construction professionals to plan, design construction and manage buildings efficiently and effectively. The BIM tool allows individuals to access the information for any purpose and it brings together all the information of the components required to construct a building (Forbs and Ahmed, 2011).

2.3 Waste in Construction

Waste in construction has been defined in different ways by researchers. Some define waste as “non-value-added work and material loss which generates additional cost along with producing minimal value to a project” Koskela (1992). However, Toyota and Formoso (1999) define waste as “Anything that is different from the minimum quantity of equipment, materials, parts and labour time that is essential for production” (Alacorn, 1995). In the journal Making do – the eight categories of waste, Koskela (2004) states that there are seven types of waste that can be identified within lean practices (Shingo 1989, Mohamed, 2015). There are seven types of wastes that have been identified in this project. The types of waste identified in this project include:

Waiting time

Waiting time refers to periods of inactivity that arise from a preceding activity that did not deliver a project on time or finish completely (Sowards, 2005). Also, when people or equipment waits for other workers to finish an activity it can also be considered as waste. The cause of waiting time is poor communication between the field functions or suppliers. It results in the cycle time increasing because of the waiting waste through which no valued added activities are completed.

Motion waste

Motion waste refers to as movement that does not add value to a task. These steps are taken by employees to accommodate inefficient process layouts, over production and defects. Unnecessary movement is a result of poor arrangement of tools, employees not aware of when tasks need to be completed and bad working practices (Formoso et al., 1999).

Processing and over-processing waste

Processing waste refers to as a processing activity that could have been avoided by changing the construction technology. Over processing waste are unnecessary steps such as double checking and added communication. An example of processing is a percentage of mortar is wasted when plastering a ceiling (Sowards, 2005).

Over production waste

Over production waste refers to as when operations continue when they should have stopped. The production of material should be stopped as soon as demand is met, it can cause excessive inventory carrying costs. It results in extra work for workers which is unnecessary, and it makes it harder to complete priority work (Banawi and Bilec, 2014).

Transportation waste

Transportation waste is caused by unnecessary movement of materials that do not support production. An example of transportation waste includes, materials transported to one site to another are common examples of transportation waste in construction (Formoso et al., 1999).

Inventory waste

Inventory waste is any materials or goods in excess of what is required to build the current structure in construction. The factors that can cause excessive inventory are incorrect estimation of quantity and overall bad resource planning. The inventory consists of raw materials, work in process and finished goods (Sowards, 2005).

Correction or Defects.

Correction or defect refers to as materials or services that does not meet the expectations and requires rework. Correction or defects are anything that contain errors from the first time that must be corrected and redone. Also, materials will have to be scrapped because of defects (Koskela, 2004).

2.4 Introduction and Application of BIM

Building Information Modelling (BIM) is defined in many ways in the construction industry. Some define BIM as “a process which focusses on development and use of a computer-generated model to stimulate the planning, design, construction and operations of facility (Azhar, et.al; 2008). Another way BIM is recognised is as “a modelling technology and associated set of processes to produce, communicate and analyse building models. Building information modelling is a verb to describe tools, processes and technologies that are facilitated by digital, machine-readable documentation about a building, its performance, its planning, its construction and later its operation” (Eastman et. Al, 2008).

BIM is a tool that can be used for the design, construction and operations of a buildings. There are different perspectives of BIM. From a design perspective, it is digital representation of a project which is used to create a BIM model. From a construction perspective, it is a model that simulates the construction and operations of a facility. From a maintenance and operations perspective, it is a tool that can improve the performance of a building and manage operations efferently. The purpose of BIM is to enhance communication and collaborations between stakeholders. BIM enhances communication and collaboration by sharing information between all participants of the project. It allows individual to access information in a timely manner. It can also reduce conflicts that can arise in the construction phase.

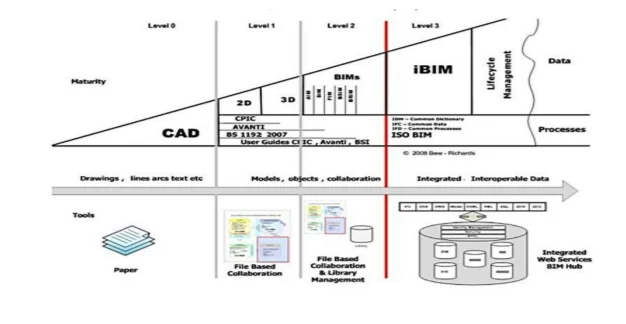

BIM Maturity

There are various levels of BIM maturity, the levels are shown in figure 1. The levels are explained as:

Level 0: Is a traditional method which consists of using paper and un managed 2D CAD.

Level 1: The drawings were done on Computer Aided Programs such as AutoCAD. It was managed CAD in 2D and 3D.

Level 2: Is BIM in a 3D environment with attached date, however, created in separate disciplines

Level 3: The future of BIM that is known as IBIM. This level will include 4D construction sequencing, 5D cost information and 6D project lifecycle management information.

The BIM tool is developing quickly, it has evolved from 2D drawings to 3D, 4D (Scheduling), 5D (Estimating), 6D (Sustainability analysis) 7D (Facility management application) (Forgues et al., 2012). 3D BIM is an integrated data model, which allows stakeholders such as Architects, engineers, contractors and builders to extract their views. This allows the project team to work collaboratively and allows participants to view the building in three dimensions. Also, 3D BIM can improve the communication of the design intent and the visualisation of the project. 4D BIM is four-dimensional modelling which is used for site activities. This type of modelling allows individuals to visualise the progress of the activities undertaken through each stage of the project. 4D BIM can provide many advantages such as builders can optimize their planning and construction activities and reduce conflicts. 5D BIM is related to cost and budget tracking activities. It can allow the project team to visualise the progress of cost over time. This type of model develops a more cost effective and efficient construction process. 6D BIM can perform energy consumption analyses. It can provide accurate energy estimates during the design stage and can lead to overall reduction in energy consumption. 7D BIM is used by facility managers during the maintenance and operation stage of construction. This is used to track asset data such as specifications, status of components and maintenance/operations. This can optimise asset management of the project from the design stage to the demolition stage.

There are various applications of BIM over the project life cycle. Some of the applications of BIM include: Coordination and clash detection, Identifying time-based clashes, Cost estimating, Code reviews, Construction scheduling. Table 1 describes some of the types of applications of BIM.

2.5 THE BARRIERS OF BIM ADAPTATION

The use of BIM within the construction industry is certainly beneficial. However, there are five main barriers to implementing BIM as it is new technology that is still developing. The five main barriers are illustrated in figure 2 and are categorised as; lack of national standard, the high cost of application, the lack of skilled personnel organizational issues, and legal issues (AEC, 2017).

Lack of National standards – According to the Architecture, Engineering, and Construction (AEC) “a few building guidelines and standards have been established in different countries. However, the use of BIM has no formal stander to generalise and standardise” (A, Salman. 2011).

High cost of application – The cost of implementing BIM is relatively high; it requires an educated IT team to support the use of the new software. The software has a high initial cost and to do a proper render it needs a more sophisticated computer to process the data (Björk and Laakso 2010)

Lack of skilled personal – BIM requires skilled individuals to operate the software and it is one of the main barriers of BIM. There are not many individuals who know how to operate BIM, therefore a lot of time is required to educate the current staff on how to use the software (A, Salman. 2011).

Organisational issue – The organisational issue with changing the traditional approach to the BIM method is it requires collaboration between the stakeholders. Also, it involves looking at the current system and establishing how BIM could add value to the current system (Newton and (Chileshe 2012, Ganah, 2014).

Legal issue – Who is responsible of the inaccuracy of the BIM model is another issue that is not clear. The implantation of BIM carries a risk that can lead to legal liability issues and court proceedings (Azhar, et.al, 2008, Thompson, et.al., 2007).

2.6 BENEFITS OF BIM

The benefits of BIM can affect the overall cost of a project, the project being completed on time and the overall quality of the project. Some of the benefits that will be discussed are; faster and more effective processes, improved design, reduces the amount of rework, improves collaboration, detection of errors and omissions and reducing conflicts and changes (Azhar et.al., 2008).

Faster and more effective processes

BIM allows information to be shared more easily as well as being more value added and reused (Azhar et.al., 2008). From a survey conducted by McGraw Hill, it showed 48% of owners say the outcome of overall projects have a high benefit (McGraw Hill construction, 2009).

Improved Design

The communication and understanding from 3D visualisation is better and allows an overall better design. The models can be designed quickly and can be performance benchmarked. This enables improvements to the design, if required (Azhar, et.al, 2008).

Reducing Rework

BIM fixes errors early in the design stage and the issues are highlighted in the plans to avoid rework. The building model is updated automatically at the design stages (Eastman, 2008). McGraw Hill states “more than 80% people agreed that BIM reduces rework (McGraw Hill construction, 2009).

Better Collaboration

According to Eastman (2008) the design time is shortened, and errors are reduced as BIM facilitates early participation of all player and simultaneously work by them. This can benefit by reduce the cost, as the value engineering is not done at the end of the design process, instead it is done simultaneously (Eastman, 2008).

Detection of errors and omissions

BIM can detect errors and omissions which saves the designer time and money. The use of BIM removes issues such as site conflicts, legal disputes and change order (McGraw Hill Construction, 2009). The conflicts are recognised at an early stage, this improves co-ordination between the designers and contractors. Additionally, it generally provides a better project process as project costs are minimised along with disputes reduced (Eastman, 2008).

Reducing conflicts and changes

Errors and omissions are noticed early in the design, which means there will be less conflicts and changes. According to McGraw Hill “engineers believe the maximum value is achieved when conflicts and changes are reduced in the project (McGraw Hill Construction, 2009).

2.7 SUCCESSFUL IMPLEMENTATION OF BIM CASE STUDIES

In this section it will summarise three case studies of projects that have been completed with the use of BIM. The projects are located around the UK in places such as Middlesex, Manchester and Cheshire. The projects have been labelled as case 1, 2 and 3. The data shown in Table 2 is the name of the project, location of the project, project sector, contract value, participant involved throughout the project and the BIM tools used for the project. The case studies will be further analysed in the result section. However, this section will summarise the benefits realised by the project by using BIM.

3.0 CHAPTER THREE- RESEARCH METHODOLOGY

3.1 Introduction to Research Methodology

The purpose of this methodology is to clarify the selected research strategy, which is the qualitative research strategy. The methodology will justify why the phenomenology and case study approach was chosen from the five main types of qualitative approaches. Also, the methods of data collection will be discussed in detail and a justification will be provided of the two types of methods that were used which are primary and secondary sources. The primary data collection method has been used through qualitative interviews and questionnaires. Furthermore, secondary data was collected from sources such as books, journals, articles. Lastly, a justification will be given on why the purposive non- probability technique has been applied to this project.

3.2 Qualitative Research Strategy

There are three research methods that can be used which are: qualitative, quantitative and mixed methods. However, the qualitative research strategy has been used for this project. The difference between the three research approaches are qualitative uses words, quantitative uses numbers and mixed methods consist of elements of both qualitative and quantitative approaches. (Newman & Benz, 1998). The two types of research methods tend to have their own benefits and drawback. A comparison contrasting the characteristics of both qualitative and quantitative research method is illustrated in Table 3 below. John Creswell states a qualitative research strategy is a process which involves developing questions and procedures and researchers clarifying the meaning of the data. From the three types of research methods, the research project uses the qualitative types of methods. The qualitative method tells the reader about the design used for the study and the qualitative research and its basic intent. The qualitative method is used because it allows direct interaction between the researcher and respondent as it allows the researcher to explore the issue in detail through interviews. Additionally, the reasons for choosing the qualitive method is because it provides personal and in-depth responses and it is based on how people think and feel Miles and Huberman (1994).

3.3 Phenomenology and Case Study Research Approach

There are five main types of qualitative approaches which are stated in Qualitative Inquiry and Research Design by John Creswell. The five main types of qualitative approaches include: Phenomenology, Ethnography, Narrative Research, Case study and Grounded Theory. Figure 3 illustrates the five types and explains the purpose, disciplinary origin, data collection analysis and research report of each type of approach (J Creswell, 2013). The approaches that have been adopted for this project are the phenomenological approach and the case study approach. According to Smith, Flowers, and Larkin (2009) the phenomenological approach is defined as a “study of human experience that shares interest in thinking about what the experience of being human is like in terms of the things that matter to us and which constitute our lived world”. The reason for choosing the phenomenology approach is because it allows individuals to understand human experience of their lived experience. This has been conducted through interviews with companies and questionnaires. This allows the researcher to express their own view on the topic without being constrained by fixed response questions (A. Giorgi, 2009). The case study approach is defined by Yin ((1984:23) as an “empirical inquiry that examines a phenomenon within its real-life context; when the boundaries between phenomenon and context are not clearly evident; and in which multiple sources of evidence are used”. Case study research can be collected through both quantitative and qualitative data. It helps explain both the process and outcome of a phenomenon through analysis of the cases and complete observation (Tellis, 1997). One of the reasons for the recognition of the case study approach is because researchers were concerned about the limitations qualitative methods in providing in depth explanations of the social problems (Johnson, 2006). According to Yin (1984), there are numerous categories of case study, however, some of the categories include: descriptive exploratory, explanatory and multiple case study. McDonough and McDonough (1997) suggest that descriptive case studies may be in a narrative form. Descriptive cases studies tend to describe phenomena which occurs in the data of the question. The researcher has a goal set which describes the data as they occur (Yin, 1984). Exploratory case studies allow the researcher to explore any phenomenon in the data. An example of an exploratory case study is a pilot study. This is crucial as it determines the protocol that will be used study (Yin, 1984; McDonough and McDonough, 1997). The explanatory case study is used to explore the data at the surface and deep level with the intention of explaining the phenomena in the data. Explanatory case studies can be used to examine multivariate and complex cases (Zaidah, 2003). Yin and Moore (1987) suggest that complex and multivariate are clarified by three types of rival theories such as a problem-solving theory, a social-interaction theory and a knowledge-driven theory The type of case study approach used for this research project is the multiples cases studies/ collective studies. Multiple case studies were selected across various locations to demonstrate the effectiveness of BIM during the construction process. The Multiple case study design displays numerous sources of evidence that supports different individual’s perception on the same study. This supports previous results and increases the level of confidence in the robustness of the method.

3.4 Methods of Data Collection

The two main methods used for data collection include: Primary sources and Secondary sources. Table 4 illustrates a comparison of the two types of sources and consists of a definition, examples and benefits of both sources. Both primary and secondary sources were used throughout the research. Primary data was collected through interviews and questionnaires. Also, Secondary data was collected from sources such as books, journals, articles. John Creswell (2013) suggests the methods of collecting data include setting out the boundaries of the study and the role of the researcher is to discuss the issues involved in collecting data. There are different types of methods for Qualitative Data Collection, some of them include: observation, interviews, documents, audio visual materials. The different data collection types are shown in table 2 and it includes the options, advantages and limitation of each type. The methods that are used to collect data for this research project are through interviews and questionnaires.

Qualitative interviews are described as a form of conversation which provides the researcher with detailed information on their area of study (Ritchie and Lewis, 2003). According to Kvale, S. (1996) qualitative interviews can be conducted through unstructured or semi structured interviews or observations, face to face interviews, group interviews, email interview and telephone interviews. These types of interviews include open ended questions to the individuals and are based on their opinions. The types of interviews used for this research project is the semi- structured one to one interview, email interview and telephone interview. This type of interview allows the individuals to express their opinions freely. It provides detailed information as the individuals have experience and knowledge in the given field. For this project, a one-on-one interview has been conducted with two construction companies. A transcript of the interview has been provided in the appendix of both companies. The interview was held with two project managers of two different companies. The two construction companies are referred to as Company A and Company B.

There are two procedures for completing a questionnaire: which are quantitative and qualitative data. Questionnaires are a better way of reducing biasness of interviews. They can be created by multiple choice, open ended and closed ended questions. The difference between the two types of procedures are: qualitative questionnaires are based on peoples believes and experience in a certain job and quantitative questionnaires are used to collect numerical data that could be used to confirm hypotheses (C. Robson, 2002). The qualitative questionnaire approach was chosen for this research project. The questions are open ended and allows participants to express their opinions in response to the area of study. Also, open ended questions allow the respondents to give positive and negative replies based on the type of questions being asked (S. Walonick, 1993). This type of approach can be useful for the researcher to collect information from participants on how individual feel about a certain issue. The template of the questionnaire undertaken for this project is illustrated below in Figure 4.

3.7 Sampling in Qualitative Research

According to M, Saunders (2009) there are two types of sampling techniques which are divided into two categories: probability, also known as representative sampling and non-probability, also known as judgemental sampling. In the case of probability samples, the likelihood of each case being selected from the population is known. Non-probability samples are based on the likelihood of each case being selected from the total population, which is not known. However, both sampling techniques can answer how and what types of research questions. The type of sampling technique used for this research project is the non-probability technique (A. Thornhill, 2009). The five main categories of the non-probability technique are: Quota, Purposive, Snowball. Self- selection and Convenience. Table 6 illustrates the five main types of non-probability sampling technique and the impact of each sample.

From the five types of data samples, the purposive sampling has been applied for this research project. Purposive sampling allows the researcher to use their judgement and select cases that meet the objectives of the research project. This sample is used with the case study research approach. Purposive samples are used widely in qualitative research, it is used for its selection of rich cases and effectiveness of limited resources. Also, it involves selecting individuals that are experienced and have a large amount of knowledge with a phenomenon interest (Patton, 2002). In relation to experience and knowledge, (Spradley, 1979) states the willingness to participate and the importance of availability of individuals is important to gather quality information. The types of purposive sampling strategies include: extreme case, heterogeneous, critical case sampling and typical case sampling. Some of the purposive sampling strategies are discussed below:

Extreme case: Extreme case sampling is special cases of data collected which enables the research to meet their objectives.

Homogeneous sampling: This type of sampling strategy focusses on sub groups and is based on the researcher judgment and selecting participants.

Critical case sampling: Critical case sampling is based on selecting critical cases and understanding what is happening in each critical case. An example of critical cases includes questions such as if it happens there, will it happen everywhere (Patton, 2002).

Typical case sampling: Typical case sampling is a strategy based on a research project that provides illustrative profile to represent its case (Patton, 2002).

Maximum variation sampling: This strategy focuses on capturing a wide range of views related to the area of study. Maximum variation sampling aims to answer questions as close to the whole population by interviewing different types of people.

The types of purposive sampling strategies adopted for this project are homogeneous and maximum variation sampling. The two strategies were used for the interviews and questionnaires.

4.0 CHAPTER FOUR – RESULTS AND ANALYSIS

4.1 Introduction to Results and Analysis

The corresponding chapter highlights the literature review outcomes in the format of questionnaires, case studies and interviews. The primary objective of the project is the efficacy analysis of the emergent lean tool of BIM within the construction industry. The reduction of construction industrial waste through BIM would be included in the literature review supported analysis as well. Further, the chapter would outline achievement of lean principles by BIM through minimisation of project cost and waste, curtailment of delays and durations of the project time. Demonstration of BIM benefits would be performed through case study result provisioning. Analytical exploration of perspective of working and studying individuals within the UK construction industry would be performed in the chapter. Interview transcripts of personnel from Company A & B would be demonstrated in the appendices and the questionnaire based research outcomes would be illustrated in the corresponding chapter.

4.2 Analysis of the Literature Review

The study performed by NBS (2018) pointed out that the highest waste production could be attributed to the construction industry. Within the UK, the responsibility of up to 32% of the waste generation in landfill of the country could be attributed to the construction industry. The generation of or removal of the construction related materials and activities such as site based construction operations, reconditioning, demolition and excavation of the soil could contribute to the formulation of waste (Shen et al., 2004; Poon, 2007; Hao et al., 2007). The dual processes of construction and demolition had contributed to the production of 77.3m tonnes of additional waste (RIBA, 2018). The amount utilised out of the 77.3m to perform landfill was 20 million. The construction industry has been suffering from the recurrent issue of waste management since a number of years. Greater effort has been directed towards the application of the process of lean production within the construction industry as a possible remedy to this problem. The lead production mechanisms emphasises on the minimisation of waste production and increment of the value of materials which are utilised within the construction industry. Multi-plethora of techniques and tools had been developed throughout the years for reduction of waste. A number of techniques and tools which have been outlined in the concerned project are Visualisation Increment, Mapping of Value Stream, Poka Yoke, BIM, JIT, 5S process and Last Planner System. The concerned project would be focusing of the emergent lean BIM tool regarding the construction industry.

The emergent lean tool of BIM has gained increasing measure of significance as a beneficial tool for the working personnel within the construction industry of UK. The utilisation of BIM has seen consistent growth in the overall lifecycle of construction projects and with the passage of time, the practice is becoming ubiquitous. The underlying reason has been the extensive benefits which could be offered by the BIM tool to the working individuals within the construction industry including the architects and project managers. Multiplicity of project phases could be served through the BIM including the construction project design stages and facility management based operational stages. The utilisation of this tool at the design stage could lead to the reduction of the generation of certain waste types involving confusion and defects. At each of the stages of the construction projects, various formats of BIM application could be utilised to manage waste reduction. Eastman, et.al (2008) have stated that various formats of BIM applications could be utilised for construction waste reduction such as:

Visualisation

Management of Facilities

Sequencing of Construction

Estimate formation of costs

Detection of class and co-ordination.

Journals, articles and case studies have been implemented to generate the necessary data for the table 7. The categories of wastes which could be minimised through BIM utilisation in the construction projects have been illustrated in the following table.

BIM and Lean

The lean operations principles could be achieved by BIM through the minimisation of the construction process generated waste as the primary principles included under the lean process. The typologies of wastes have been illustrated by Table 7 and these could be identified within the construction procedures so that the BIM applications could be identified through which waste reduction could be managed.According to Koskela (1992), Lean process is comprised of 11 different principles including the minimisation of the activities which do not generate any value, achievement of the deliverables which are required by the client, variability reduction, curtailment of time cycle, maintaining of quality in tandem with the simplification of complications, achievement of deliverables through flexibility, process transparency management, control management, consistent process improvement, improvement of balance flow through conversion improvement and benchmarking.The benefits of Lean and BIM are multifarious. The effectiveness of BIM as am lean tool has been the vitality of it in the enhancement of efficiency and productivity rates within the concerned industry. The share of non-profitable and unnecessary activities is eliminated by BIM. This is achieved through clash detection utilisation to detect the various clashes and collision so that non-value adding activities could be removed. This leads to curtailment of project duration through maximised value addition for the customers (Davies and Harty, 2013). Early correction of clashes and alteration of contentious situations within the design stage could foment extensive coordination between all the contractors with the elimination of possibilities of conflicts arising and this saves time.BIM is considered to be the lean tool which could perform the dual responsibilities of construction waste reduction and minimisation of project costs as well as the shortening of the required project duration through the optimisation of the sequences of construction efforts. The required hours of rework are reduced by the BIM application and cycle time as well as product costs are also curtailed through this measure. Rework causes delay in projects and cost overruns also occur while the construction could reach the final stages. Visualisation of workflows is provided with an effective control platform through the BIM applications. This enables greater flow of tasks and collaborations between the onsite and offsite workforces and other related project individuals (Sacks et al., 2010). RFI clarified unresolved issues in any project and clarity is enhanced for the contractors through BIM based visualisation which expands coordination and communication within the project working teams. These curtail the required changes. Greater utilisation of structural material which have been prefabricated are utilised through the BIM tool and these contribute to the efficiency, effectiveness, progression of estimated schedule and estimated cost reductions of the project against the actual schedule duration and cost incurrence. 3D models are utilised through the BIM to facilitate interpersonal communication streamlining the construction process. Fast paced decision formulation and improvement of understanding of the engineers, contractors and design team members are two direct outcome of these improvements (Greenwood et al., 2008; Shelden, 2013). Confusion elimination, enhancement of understanding of individuals regarding costs, space and functioning of the building project and clarification of the project aims are provided by BIM through confusion elimination. Journals, books and articles have been utilised for the research and development of Table 8. The illustration of BIM applications as well as the method of essential lean principles application through BIM has been achieved in the following table.

Literature review and findings have outlined the construction waste types in the manner of time lost in waiting, excessive production, inventory based waste, motion, transportation, defects and confusion. It also affirmed that BIM reduces construction waste. The results achieved were similar to the results of AEC professionals. Table 9 outlines the outcomes developed by the AEC professionals concerning construction industrial waste. AEC professionals have recognised the BIM tool for waste reduction.

The results specify that error and waste reduction could be performed through BIM in the construction industry in spite of the shortcomings such as problems related to information flow shortages and dearth of pre-construction coordination. Simultaneous implementation of Lean and BIM can solve these problems since the benefits achieved could be doubled through simultaneous application of BIM and lean tools such as LPS and JIT. The simultaneous application could contribute to greater offsite work completion. The completion of the design phase could be followed by the passing on of the information to individuals for the purpose of prefabrication. Simultaneous application of Lean and BIM could reduce waste to a greater extent in comparison to any of the systems being applied individually. Workflow could be enhanced through the simultaneous application of the LPS and 4D BIM since this assists in greater detailed planning which improves the pre-construction phase preparations. BIM, despite reducing occurrence of conflicts in the construction processes, is ill suited to develop solutions of inter-team conflicts within the project scope. Simultaneous implementation of BIM and LPS could resolve such intractable conflicts as BIM could detect the mistakes prior to the commencement of the construction phases and LPS permits the effective planning of the work disciplines by the project teams which could ensure collaborative functioning towards elimination of the obstacles such as inter-team conflicts. An instance of combined application of Lean and BIM resulting into a positive culmination is the formulation of KanBIM. Positive feedback has been achieved by this system on the base of experiences shared by personnel working on the construction sites. This attests to the logic of simultaneous implementation of Lean and BIM rather than implementation of them individually. KanBIM implementation advantages involve process visualisation ability enhancement, reduction of time wastage, inter-team communication and coordination enhancement.

4.3 Analysis of Case Studies

The demonstration of the achievable advantages in construction disciplines through implementation of BIM was the objective of undertaking the case studies. The conclusions achieved had been that the emergent tool of BIM is effective in terms of early application within the design phase and this could assist in the reduction of confusions as well as in the correction of defects and errors and it addresses the dearth of proper understanding at the inter-team operational levels. Savings of costs and profit earnings were achieved in the projects which applied BIM, as per the case study based analytical outcomes. The case study based findings are indicative that BIM could be applicable at all of the project stages including the design to the operational and maintenance stages. Additional findings had been the confirmation of BIM contributing to waste reduction and achievement of essential principles of lean management including curtailment of non-value generation activities. Further benefits achieved through the case studies are as the following:

Clash Detection application to outline errors prior to the construction phase commencement

Effective and specific visualisation of conflicts prior to the pertinent phases

Energy utilisation optimisation

Saving expenditure and time

Design consultation phase based collaboration improvement with effective sharing of project information.

Collaboration improvement between consultants while designing through regular sharing of project information.

Enhancement of performance and quality of construction through BIM application.

BIM has permitted the case studies to reduce required expenditure and time through application of component designing through 3D methods which could facilitate off-site fabrication of constructional components. Early completion of projects prior to the scheduled deadline has been another efficacy of BIM. The case study derived benefits and lean principles obtained through BIM application in the construction industry have been illustrated in table 10.

4.4 Analysis of Interviews and Questionnaires

The exploration of perspectives of working and studying personnel within the construction industry had been the objective of the interviews. These furnished extensive information concerning the awareness levels of Lean and BIM applications within the construction industry. Appendix 1 demonstrates the transcripts of both of the interviews conducted with the dual project managers. The work experiences of the individuals from Company A and B in the construction industry had been 20 and 5 years respectively. Both the companies identified various types of wastes such as deficiencies, extensive time of waiting, redundant processing, excessive inventory elements, redundant production and confusion. The literature review based findings also attested to the existence of similar measure of construction industrial wastes.

Company A Results

Techniques and tools of Lean construction

Lean construction techniques were in the knowledge of the project manager as the person identified the lean tools such as Visualisation Increment, meetings over determination of daily huddles, JIT, BIM.

Identification of waste generation reason

Inventory excess

Motion based wastage

Transportation deficiencies

Time requirement while waiting

Benefits

Certain benefits of BIM implementation were identified by Company A project manager. These have been the curtailment of occurrence of omissions and errors during the design phase as problems could be assessed early on, mitigation of conflicts and rework necessities occurring between work teams, curtailing change orders to save project expenditure and optimisation of benefit achievement through saving of time. Further, timeframe reduction regarding project durations and deterring against RFI could as well be counted. Prevention of rework emergence could save labour costs as well.

Disadvantages

The primary disadvantage outlined by the Company A has been the excessive expenditure associated with the tool implementation. Company A is off the opinion that only large enterprises are inclined to utilise BIM as this is an expensive tool. Another issue has been outlined as the dearth of proper expertise regarding utilisation of this tool since greater investment is required to train the working personnel to become accustomed with such a tool. Company A presumes BIM as an effective construction lean instrument which multifarious benefit deliverables as well as the ability to waste removal through improvement of construction project qualities.

Company B Results

Techniques and tools of Lean construction

The Lean process has not been implemented by Company B due to the dearth of familiarity in spite of the positive of presumption of it being a construction waste reduction approach. Visualisation Increment, meetings over determination of daily huddles, JIM and BIM have been utilised by Company B.

Identification of waste generation reasons

Excess production

Transportation

Redundancy of processing

Ron-corrective processes

Benefits

According to the Company B project manager, the identified benefits through BIM implementation involve enhancement of coordination and collaboration between the working project teams, reduction of confusion and contentions, clarification of project objectives, mitigation of inaccuracies regarding conflict identification, document updating, structural component re-formulation at off-site locations and increment of project cost savings.

Disadvantages

The primary disadvantages are the relative unfamiliarity of the general populace with the BIM tool and the comparative expensiveness of the software. Another significant disadvantage is the relative dearth of available expertise regarding the BIM application in construction projects. Company B is off the opinion that BIM could be effective in terms of waste reduction through the project progression, initiating from the design and culminating in the operations stage. The company is in favour of considering BIM as an effective achiever of lean principles and being beneficial for the construction disciplines.

Analysis of Questionnaires

The questionnaire application purpose was the exploration of the individual perspectives of different working and student personnel belonging to the construction industrial discipline. 20 different questionnaires had been completed as these have been demonstrated in Appendix 3. The majoritarian responses have formulated the questionnaire application outcomes. The utilised 6 questions of significance in the questionnaire had been related to the Lean Construction based opinions, categories of construction wastes, general awareness regarding the techniques and instruments related to Lean Construction, defining BIM accurately, opinions on advantageous deliverables of BIM and the possibility of leaner construction generated by BIM. Only 6 of 20 questionnaires have been selected for assessment purposes. Table 11 has demonstrated in the subsequent page, the achieved outcomes from the 6 respondents who had been students and working personnel in the construction discipline. Such respondents are designated in the research as participants 1-6. Figure 5 has illustrated a sample questionnaire and Appendix 3 has demonstrated the remaining questionnaires in the completed format

The interviews undertaken have established beyond reasonable doubt that advantages of BIM outweigh shortcomings. The case study based data have attested to the BIM application benefits. In spite of this, certain measure of uncertainty still exists concerning the paucity of endorsement of this tool by greater number of construction industrial professionals. The interviews outlined the core constituents of some format of discouragement of BIM and one of the major concerns is the inadequate measure of expertise regarding the BIM application. The excessive cost of and relative shortage of effectively trained individuals in BIM, according further resources to the utilisation of this tool could be ill-advised. The cost structure makes it incrementally difficult for the SMEs to utilise BIM in comparison to large enterprises. This has deterred the professionals from further investment into BIM. The evidence of beneficence of BIM as a tool requires greater substantiation through evidences also in the concerned industrial sector. The term and attributes of Lean Construction are not known to most of the individual workers and students of the construction sector, as per the questionnaire outcomes. Some familiarity existed for working personnel in comparison to the students of the construction industry. However, university modules had made some students aware about a number of lean tools. The questionnaire findings outlined that BIM is within the knowledge sphere of most of the respondents. However, confusion regarding the attributes of BIM still persists within the construction industrial workforce. This confusion encompasses the BIM protocol mandate of the UK governments as well. Apart from these, an extensive majority of the individuals had been cognisant of the benefits which BIM application could bring forth regarding the construction projects. The participants utilised, out of all of the 5 provided definitions regarding BIM, the frequently applied one of BIM being the technology of modelling which has been a sequence of processes to communicate, produce and analyse the models of building procedures. The euphemism of modelling of construction information is utilised for the purpose of illustration of tools, technologies and processes which are assisted through the machine directed and digitally performed documentation methods. This involves the details of any building, the performance of it as a structure, the planning process, the construction phases and the operationalization of the entire edifice (Azhar, et.al; 2008). Engineers, contractors and design specialists utilise BIM as an instrument for presentation of databases and graphics of any construction undertaking for the purpose of enhancement of project based inter-stakeholder communication (Smith, 2007). The primary advantages of BIM had been outlined by the participants and these involved reduction of rework and detection of possible contentious points. The responses generated by the case studies and by the questionnaires matched each other and this attested to the positive implications of BIM application in construction projects. In spite of the ignorance of most participants about the lean terminology, every participant had been unanimous about the ability of BIM of effectively transforming any construction process into a leaner procedure.

5.0 CHAPTER FIVE – DISCUSSION AND CONCLUSION

How effective is the emerging lean tool BIM, in the construction process?

The literature review, interviews, cases studies and questionnaire based obtained results have clarified the fact that the BIM, as an emergent lean tool, could have an extensive impact on the construction disciplines. BIM enables the professionals to get involved in the projects at the early phases and this contributes to the waste reduction. The assessment of books, articles and journals based literature has outlined BIM to be a tool of great significance which could be compared to the various other techniques and tools of lean management since it fulfils the lean principles. The benefits obtained from the BIM utilisation could establish it as an effective tool to be utilised in the construction industry to reduce waste. The AEC professionals have also suggested the construction waste reduction capabilities of the BIM, thus, supporting the earlier research assertions. The case study based outcomes have specified that BIM, apart from the achievement of lean principles, also provide added benefits in construction undertakings. Such benefits involve enabling of savings on various project costs as well as change order costs, reduction of the time requirements through reduction of rework, conflict and change reduction in the course of construction and improvement of productivity. The greater and incremental realisation of individuals about the benefits which could be derived from the BIM has contributed to the utilisation of BIM as a lean tool in the construction projects. The case study based outcomes have been supported by the results derived from the questionnaires and interviews. The questionnaires and interviews have demonstrated the genera awareness of the individuals related to the construction industry of the vitality of the BIM tool and the data derived from these two methods indicated the expansion of BIM utilisation in greater numbers of projects as a preferred tool. Such information obtained from the questionnaires and interviews also have established that the positives of BIM generally outweigh the negatives. The information have also answered various unresolved questions of which one is about the reason of BIM not getting utilised greater by the professionals of the construction industry in spite of various advantages of this tool. The dearth of knowledge and expertise has been outlined by the interviews concerning the relative shortage of BIM utilisation as a lean construction management tool. Another point which has been outlined has been the relative difficulty of BIM implementation, particularly in the small companies due to the extensive training requirements for the tool utilisation and the comparative high cost of the tool.

This factor has assumed extensive significance concerning the generation of hesitations in the professionals regarding investment in BIM. The potentials of deriving maximised benefits from BIM could surpass the exorbitant investment requirements. In the passes of time, the application cost could be outweighed by the BIM offered savings concerning the extension of the projects. The BIM application undertakings by various project participants have outlined the outcomes which have surpassed the initial expectations in every means.

The primary objectives of the projects are as the following:

Determine how the lean tool BIM can minimise the types of waste identified in the construction industry.

Determination of the methods through which the minimisation of the industrial construction project based waste generation could be achieved.

Exploration of the diverging perspectives of individuals currently operating and studying within the structure of the construction industry through utilisation of questionnaires and interviews.

Demonstration of the BIM provided benefits from the three case studies concerning the success of the BIM applied construction projects.

The obtained results have demonstrated that effective reduction of the construction process related waste does occur through the application of BIM. The waste generation sources in the construction industry could be determined to be defects, confusion, rework, redundant processing and productions and insecure working conditions. The results have also attested that BIM could achieve lean production principles effectively. Uncertainty persists concerning the lean tool principles of BIM. Notwithstanding this, the outcomes obtained have established BIM being a lean tool effectively which could provide greater lean construction procedures.

Finally, the BIM derived benefits could be realised in the following manner:

1: Provisioning of clarified comprehension of the project design.

2: Leaner construction method achievement assistance.

3: Assistance in identification of conflicts and contentions.

4: Fostering of inclusiveness of the project team members.

5: Emphasis on the early involvement of professionals within the construction project design process

6: Enabling the project management process to reduce project costs through reduction of rework and preclusion of change order management.

The following are supported by the data tables demonstrated within the analysis and results section of the preceding research project:

1: Reduction of the identified construction process waste types through the application of BIM.

2: BIM does achieve success in attaining lean principles.

3: BIM could be considered to be a generally popular tool with greater number of individuals having greater knowledge of it in comparison with Lean management.

4: Multiple benefits could be derived from BIM.

The obtained outcomes have suggested that the BIM, as an emergent lean tool, does impart a profound impact on the construction industry.

RECOMMENDATIONS

Implementing BIM and Lean simultaneously.

Ensuring the project team have a greater understanding of BIM and Lean

Encouraging more companies to use BIM

Providing trials to companies

The thesis shows implementing BIM can have benefits in the construction industry. Ongoing research into the successful implementation of BIM has shown that combining BIM and Lean results in greater benefits for the construction industry. BIM and Lean have generally been applied separately, however, the combined effect of the two is much greater than the effect they have individually. The initial design stage is a significant point in the construction process, due to its effect on the subsequent phases of the construction lifecycle. By implementing BIM and Lean simultaneously, early in the design stage, the construction project is more likely to be completed without any defects. As a result, the overall construction lifestyle will run more effectively. BIM and Lean synergies can result in the project team to know beforehand the work that is required and its exact location. Also, BIM and Lean can provide a detailed management of the working process. More specifically, using the lean tool LPS and BIM alongside one another, can result in the best work sequence between participants and minimise the duration of the activities.

Another recommendation is to ensure the entire project team understands the combined use of BIM and Lean, in great depth. This will then enable resources to be allocated efficiently, by allowing a continuous flow which is planned without the excessive or under use of resources. There also needs to be more encouragement for companies to implement BIM into their regular work. By doing so, construction professionals will realise the benefits that BIM can have on the construction process. Data collected from the questionnaires revealed that most participants were familiar with BIM, however, many employees within the construction industry are still confused about the use of BIM and Lean. For this reason, it may prove useful for the construction industry to investigate this issue and provide employees with more training in the use of BIM. If employees receive more training, they are likely to become more familiar with using BIM and develop a greater understanding of the tool. As a result, companies will be able to gradually implement a more regular use of BIM within their projects, which will lead to more efficient results.

The cost of the BIM software is expensive and requires a substantial investment. However, the advantages of BIM can provide savings and profit in long term. An additional recommendation is to provide a free trail to companies with a small budget to give them a chance to use the software and experience the benefits it can have on projects. Once the company has used the tool and understood the benefits it can have, they are more likely to continue using it in the future.

Future Research

One research area to be investigated could be finding out the cost advantages of BIM in relation to the cost of acquiring the software. If companies are aware of how much money they could save from using BIM, they would be more inclined to integrate its use into their regular work. This would, therefore, lead to more efficiently completed projects across the construction industry. Another recommendation for future research could be to investigate the synergies between BIM and Lean, in order to discover the effectiveness of applying both concepts together.

REFERENCES

- Alarcón, L.F., (1993). Modelling Waste and Performance in Construction

- Alarcón, L.F., (1994). Tools for The Identification and Reduction of Waste in Construction Projects

- Alves, T., Milberg, C. and Walsh, K. (2012). EXPLORING LEAN CONST RUCTION PRACTICE, RESEARCH, AND EDUCATION. Engineering, Construction and Architectural Management, 5, 512-525(0969-9988), pp.433-435.

- Azhar, Salman. 2011. "Building information modelling (BIM): Trends, benefits, risks, and challenges for the AEC industry." Leadership and management in engineering (American Society of Civil Engineers) 11: 241-252.

- Bertelsen, S., (2004). Lean Construction: Where Are We and How to Proceed? Lean Construction Journal 2004

- Banawi, A. and Bilec, M. (2014). A framework to improve construction processes: Integrating Lean, Green and Six Sigma. International Journal of Construction Management, 14(1), pp.54-55.

- Eastman, C., Teicholz, P., Sacks, R., And Liston, K., (2008). Bim Handbook: A Guide to Building Information Modelling for Owners, Managers, Designers, Engineers and Contractors, John Wiley and Sons, Ny, 2008.

- Forbes, L. and Ahmed, S. (2011). Modern construction. 1st ed. Boca Raton, FL: CRC Press, pp.53-55.

- Green, S., (1999). “The Missing Arguments of Lean Construction”, Construction Management and Economics,Vol. 17, No. 2, 1999, pp. 133 –137.

- GREEN, S. (2002). THE HUMAN RESOURCE MANAGEMENT IMPLICATIONS OF LEAN CONSTRUCTION: CRITICAL PERSPECTIVES AND CONCEPTUAL CHASMS. Journal of Construction Research, 03(01), pp.147-166.

- Green, S. and May, S. (2005). Lean construction: arenas of enactment, models of diffusion and the meaning of ‘leanness’. Building Research & Information, 33(6), pp.498-511. Winch, G. (2006). Towards a theory of construction as production by projects. Building Research & Information, 34(2), pp.164-174.

- Ho, P., & Matta, C. (2009). Building better: GSA's national 3D‐4D‐BIM program. Design Management Review

- Jørgensen, B. and Emmitt, S. (2008). Lost in transition: the transfer of lean manufacturing to construction. Engineering, Construction and Architectural Management, 15(4), pp.383-398. Pettersen, J. (2009). Defining lean production: some conceptual and practical issues. The TQM Journal, 21(2), pp.127-142.

- Mohd-Zainal, A., Goodyer, J., and Grigg, N (2011). Organisational learning to sustain lean implementation in New Zealand manufacturing companies, 3rd International Conference on Information and Financial Engineering, IPEDR, 12, 151-156

- Navon, R. and Sacks, R. (2007). Assessing research issues in Automated Project Performance Control (APPC). Automation in Construction, 16(4), pp.474-484.

- Kvale, S. (1996). InterViews: An Introduction to Qualitative Research Interviewing. 1st ed.

- Thomas, H., Horman, M., Minchin, R. and Chen, D. (2003). Improving Labor Flow Reliability for Better Productivity as Lean Construction Principle. Journal of Construction Engineering and Management, 129(3), pp.251-261.

- Smith, D., (2007). AIA: An Introduction To Building Information Modeling (Bim), Journal Of Building Information Modeling, Fall 2007

- Yin, R., (1994). Case study research: Design and methods (2nd ed.). Beverly Hills, CA: Sage Publishing.

- Zaid K. AI Hussein. (2016). Using Building Information Modeling (BIM) and the Last Planner System (LPS) to Reduce Construction Process Delay.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts