Supply Chain Insights: UK Small Arms and Global Automotive Products Compared

Introduction

Comparing, contrasting and evaluating two product supply chain helps in gaining understanding differences and similarities between two different sectors or industries. The comparative study is based on two product’s supply chain, in which the chosen products are UK military small arms and international automotive products. The UK small arms and global automotive industry might seem incomparable in terms of the way they operate and supply their products. The study focuses on evaluating the supply chain and logistics operations for both the products for better comparison of the strategic planning of the organisations to sustain in the business and secure future sustainable development. Along with it, the report will evaluate value-adding models, the contribution of the supply chain towards customer service, cost of the chain, IT, technology innovation, the influence of external factors, cultural differences, etc. Small arms sector is generally having a product line of small ammunition and guns. In this, the supply chain of 5.56mm ammunitions has been considered by the sector. Also, small range pistols and other tools are being covered in the small arms. However, global automotive is all about production and supply of small and big scale vehicles for commercial and retail purpose. This study delves into the complexities of these supply chains, highlighting all the challenges and opportunities they present. For students exploring these topics further, professional guidance in business dissertation help can offer valuable insights and support in navigating the intricacies of supply chain management and strategic analysis.

Structure and role of the supply chain

Excellence in the manufacture of automobile industry relates to the supply chain organisations and is achieved through many ways that include cost, quality, delivery to the OEM (original equipment manufacturers) and the customers (Khan, 2019). The supply chain of small arms and the automotive industry focuses on the production and delivery system to manage their supply chain and logistics (McCormack, 2019). The industry follows certain factors including production management, Operations, technological advancement, warehouse management, developing green supply chain and logistics operations that help automotive manufacturers to produce efficient inbound supply chains. The process of facility selection is vital for automobile manufacturers as ideal decisions regarding the entire supply chain are made to identify the further opportunities and mitigate the high cost of production and distribution for efficient supply chain management (Blum, 2019). The international automobile industry also focuses on risks that are associated with the company supply chains in terms of quality assurance, tariffs and China’s economic slowdown (Lo, 2019). For managing good supply chain and logistics operations for example in small arms industry, the company focuses on Tariff structure and the economic condition of China to export the products and generate revenue and apart from that quality assurance is mandatory to maintain green supply chain, managing waste and strengthen the distribution network of the company.

For the environmental risk regarding CO2 emission, regulations effectively considered and maintained by the brands before supply to the retailers and consumers.

The above diagram figure 1 illustrates the supply chain model used by major automobile industries and the various parts of the model constitute manufacturers, suppliers, dealers and the consumer In order to place the organisational products and manage the customers globally. The supply chain network for automobile industry is effective to manage asset receive, stock management activities, production assembly and serving the customers efficiently. To have an optimal production rate, the supply chain model is used extensively and has proved to be a successful invention in the automobile industry (Itoh et al., 2018). The automotive industry manages all its activities using systems based on ERP and Improper reference of Supply chain can also be resolved by using the supply chain model to deal with the operational risk such as lack of quality raw materials, mismanagement of the production activities, lack of efficiency in distributing the final goods with safety, poor management of stock and warehouse and the financial management during the production and operations at the automotive organisation.

The key purpose of the supply chain model and process in both the sectors is to improve the level of distribution and effective work presence in the context of inventory management and operations are highly dependent on supply chain, so that, the organizations can manage the quality raw materials, develop proper production process, manage economies of scale, minimise cost of production, maintain the warehouse, safety of the products and distribute the products as per the customer’s demand.

In comparison, the UK small arms industry can be defined as 7.62 and 5.56 ammunition and operates at small-scale that is strictly and disciplinary controlled by national and global legislation (Tan, 2014). The small arms market within the country includes both light weapons and small arms (Hartley, 2018). The Small Arms supply chain is designed to operate at the duration of war and the survivability outstrips, which the UK small arms industry followed five major principles such as:

Looking for further insights on Centrica Supply Chain Strategy? Click here.

Efficiency

Simplicity

Cooperation as process enablers

Foresight (Emmanuel-Yusuf, et al. 2017)

Agility as output enablers

Figure 2 above of the UK small arms supply chain industry controls production line and ensuring the process of supply to be as lean as possible and aggressively pursue modern quality management techniques. The assembling area of the small arms products is linked with the strategic area and the UK Small Arms Industry implementing advanced logistic support site which carries out the supply of the products with the forward logistic site (Blum, 2019). The supply chain structure focuses on meeting the stringent quality standards which are far more modern and rigorous in comparison to the automotive industry (Hartley and Belin, 2019). These two industries are chosen in order to identify the supply chain management system and logistics operations in the small arms and automobile sector, where there are presence of efficient suppliers and distributors who try to develop green supply chain for securing future sustainable growth by ensuring its quality operations.

In terms of risk management, small arms industry within the UK faces quality of the products, enhanced tariffs and costs due to Brexit, COVID19 and illegal supply of the small arms (Fan and Stevenson, 2018). In the supply chain, all the risk factors included and considered by the industry through cost-effective strategies and implementation of standard costing (Najjar, et al. 2019). Different risks are being faced such as the global pandemic outbreak of illness, financial, security, safety and operation (Grabot et al., 2014). This further affects the supply chain management of the small arms industry negatively, where due to lack of demand of the customers in the market as well as labour retrenchment in the organisations, the supply chain cannot be managed efficiently, which further raise the cost of managing the distribution network and production activities in long run. According to Hartley and Belin (2019), Financial risk might be faced by small arms industry within the UK due to improper allocation of funds as well as production requires high financial support. On the other hand, security risk regarding hacking of secret and patent documents by unethical parties (Hartley, 2018) which will increase the illegal production and distribution of small arms with. Fan and Stevenson, (2018) affirm that employee’s safety during the trial and production of small arms needs to be controlled properly for the effective supply chain. Quality of both the small arms industry and the automotive industry need to be managed well, however due to the pandemic scenario of infections safety and security and financial crisis, the organisations also fail to conduct in depth research and development, invest more on production of the final output of the firms as well as they are also suffering from retaining the proficient suppliers for managing the strong supply chain. Hence, there is a great role of supply chain to manage the production and operations of the small arms and automotive industry, where the suppliers are proficient to arrange the raw materials, share the market information related to current industry trend and customer’s preferences, managing the warehouse and distribution network, maintain stock of the products and deliver high quality products to the customers within effective time (Oliveira and Gimeno, 2014).

Value-adding models in international supply chain management

A company can be summarised as a collection of designing, producing, marketing, delivering and supporting its services and products (Khan, 2019). The automotive industry aims to create automobiles having a greater value to the customers overall as identified in future 3.

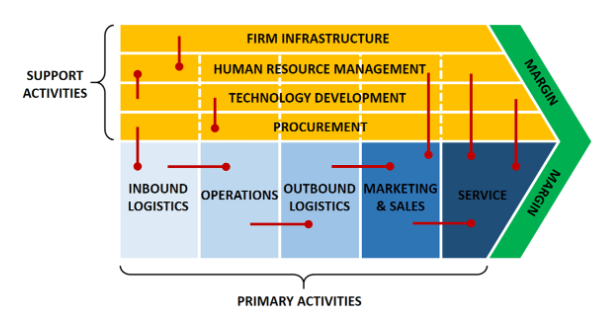

The Automobile industry suppliers follow a value chain that facilitates the manufacture and delivery of the bought inputs (Gobetto, 2013). Before reaching the destination, that is the buyer, the products go through the value chain and can be classified into primary and support activities as indicated in the above diagram. Agreed, that the value activities are of primary concern for competitive advantage, the value chain is a composition of dependent activities that facilitate in better consideration of quality practice (Terlep, 2019). The automotive industry focuses on support activities by developing the firm infrastructure, managing human resource at the workplace through providing them monetary and non-monetary incentives as well as technological development and procurement management and the automotive industry is efficient to utilise cutting edge technology to develop and design creative products. On the other hand the primary activities are inbound and outbound logistics, marketing and sales, operations and services, where the automotive companies manage their inbound and outbound logistic and utilise the quality raw materials to maintain the product quality. Additionally, the companies try to improve marketing and sales to serve the customers in better way and in the recent digitalisation era, they are successful to connect with the customers and serve them 24*7 through developed online activities. Supply chain in this regard plays a crucial role to manage the primary activities to maintain logistics system where the suppliers are efficient to protect the warehouse, product quality, safety of the automotive products for organisational excellence.

In the UK small arms industry, the effectiveness of the value chain process generally measured by the level of customer satisfaction where the companies aim to deliver high quality organisational products on time at effective place to maximise consumer’s values. Under this model, small arms effectively use the lean model and Just-in-case (JIC) to ensure that all the products are produced as cost-effectively as possible from a single location that helps the industry to add significant value in the value chain and reduce the cost of the production for generating more profitability and revenue (Elms and Low, 2013). Such kind of aspects allows improving the risk factor and ensuring that quality work management can be considered by using different elements accurately, the risk and quality measures are being improved in context to supply chain (Karp, 2014). Stock levels use their large-scale reserves with some associated risks by eliminating waste of production and there is great role of the supply chain where the suppliers are efficient in waste management by transferring the waste to landfills and reusing the renewable resources to protect the environmental sustainability in both the industries (Lo, 2019). The quality management system allows the business to establish their added value, which is measured, in return, enable the industry to evaluate the value chain and the product flow-path optimisation technique helps in providing accurate decisions with the assistance of smart techniques where the firm infrastructure to product the organisational products at small arms industry, technical advancement to manufacture the products innovatively and human resource management by hiring the experienced staff are effective to maximise the quality of the small arms (Terlep, 2019). There is high impacts of supply chain and logistics management on the organisational activities in the small arms industry, where the suppliers and the distributors are proficient to manage the inbound and outbound logistics where the stock of the products in both small arms and automotive industries are managed well (Macola, 2018). To have focused results, a value chain model gives both the business assurance of the adding value within the products and ensures the production of quality finished goods at a competitive rate in the market (Small arms survey 2010, 2011). The Porter’s value chain model is one of the effective ways to manage supply chain in the small arm industry rather than Lean management and JIT strategy. Through implementing Porter’s value chain, it is easier for the small arms industry to manage their day to day operations and maximise their performance through strengthening their supply chain. Through this model, small arms industry can manage their human resource and implement latest technology for betterment of their operations.

Supply chain cost

The supply chain instead of having concern on the strategies, commerce and logistics can still be considered under pressure regarding cost and the OEM’s (Original Equipment Manufacturers) which are initiating several cost-reducing concepts and factors (Seuring and Goldbach, 2013). Risk identification cost also includes sectors cost of the supply chain can be balanced in a significant manner and the technical advances are creating opportunities (Dobson and Dobson, 2012). The urge of the customers for better, cheaper vehicles is increasing cost pressure within the supply chain and consequently, the automobile supply chain is reforming its structure to adjust to the changes and the Supply chain cost management helps in implementing quality work activities (Johnson et al., 2011).

On the other hand, small arms are surrounded by the right and quality suppliers which are the main contributor to the soaring cost of the supply chain (Tilstra, 2012). For that purpose, UK small arms focus on the most reliable supplier with the most competitive prices. The industry has a proper evaluation strategy of the key drivers of supply chain cost including investment cost, procurement cost, transportation cost, production cost, and inventory cost (Brandenburg, 2016). However, rising oil prices are affecting the cost of the supply chain for specific raw materials and products (Gurnani et al., 2012). According to Dobson and Dobson (2012), defence contractors had to find an alternative way to cut the prices without making any sacrifice in the quality of the product. Both industries face risk to maintain cost while supply, sourcing the products and services to the businesses and consumers as it is becoming complex (Hanson, 2017). For instance, automobile industry at the global level is facing risk in supply chain cost and for that purpose, the industry mainly focusing on protecting the supply chain from costly and serious disruptions and also develop strategic plans for the inventories and different locations for manufacturing the products (Macola, 2018). In the case of small arms, the risk of supply chain cost mainly influenced through the production of many products and sourced them by considering legal terms and policies. The small arms industry within the UK is mainly focusing on improving the supply chain through segmenting and regionalising the supply chain (Giannakis and Papadopoulos, 2016).

Technical innovation, IT and communication

The latest innovations in the technical, IT and communication fields have made a profound impact on the automotive manufacturers throughout the globe (Welfens, 2012). Thus, e-cars have become the need of the hour and there is a strong need for the industry to match the demanding technical needs of the customer (Macola, 2018). With enhancing technology, the international automobile industry is suffering from technological risks in terms of manufacturing products with implementation of appropriate techniques so that the products can meet the environmental standard of the specific country (Macola, 2018). Risk management techniques have been applied by the industry that includes avoidance, retention, sharing, transferring and reduction of loss to reduce the impact of the challenges (Brindley, 2017). The automotive industry adopt the new strategy of manufacturing electric cars with latest and susti8amnble battery facility which help further to maximise the environmental, sustainability. Hereby, technological advancement lays a crucial role in the automotive industry to develop and design efficient cars for the customers which would be environmentally sustainable.

Since the last decade, small arms industry in the UK has been overlooking technological innovation factor, information technology and communication channels which can be a significant risk (Hanson, 2017). The technical advancements inspire the UK small arms industry to invest and produce technically small arms weapons to succeeded to a certain extent and innovation enhance the design and layout of the small arms and light weapons that include non-traditional materials (Lieber, 2018). Hence, for quality management, it is mandatory for the small arms industry to adopt new technology to fast and sustainable supply chain development where the suppliers can manage the stock of raw materials as well as final products in the market. The technological advancement is also effective for the small arms industry to manage their ERP system, and handle the procurement through online and automatic technology and software. New technologies and enhanced IT have risks for multiple efforts in addressing the unlawful business in small arms (Ford, 2017). The UK small arms industry is using laser technology on the high basis that also involved micro-stamping and the self-steering bullets also implied with Teledyne technologies (Ramli et al., 2018). This further provides a scope to the small arm, sector to enhance their operation and ensure organisational excellence successfully by ensuring effective quality management practice in the supply chain.

Distribution consideration for quality management

Just in Time

Just in Time (JIT) is an approach that is very famous amongst both the automotive and the UK small arms industry worldwide (Dou, 2013). JIC has many advantages as it does not incur much capital investment at the initial phase of manufacturing and it is successful in increasing efficiency and the wastes are on the decline within the automotive industry (Pinto et al., 2018). The requirement is that the proper estimation of material demand should be done, low inventory levels are required, and the supply chain is given due importance. (Emmanuel-Yusuf et al. 2017). JIT approach applied in the automotive industry because of the promising advantages should have a steady production rate and talented workmanship in both the industries which further helps to maximise quality (Kaynak, 2018). Another advantage is that the manufacturer can switch between the choices of products easily without much effort and just buys the raw material as much needed which reduces the cost incurred to a large extent (Smith, 2019).

Just-in-Case (JIC)

This model is commonly used by companies especially in the western world to supply goods and services to the other part of the world (Battini et al., 2012). This model facilitates quick supply of products and reduces risk of inventory management (Dhanapala et al. 2019). In a situation where is a natural disaster or disruption of flow of products, it affects the distribution of goods and services. These cases led to the establishment of Just in time so that firms may consider a safety stock by storing some inventories at certain strategic locations (logistics hubs, distribution centres, warehouse) to be shared by multiple supply chain partners. Toyota, for instance, keeps certain cars and car parts at a certain location at vantage location to enable all retailers in the nearby region to have access to the products. This helps to achieve higher customer levels and at the same time, increase in purchases of the product and reduces the cost that the firm might incurred (Tang, 2006). According to Dhanapala et al., (2019) JIC helps in identification of risk and ensure that raw materials are being in a good manner and improved in predicting customer demands by small arm sector in the UK.

Enterprise Risk Management (ERM) Model

It is a famous ERM model adopted by the automotive industry for handling risk management and risk monitoring which is categorised into strategic, business, business support and risk compliance (Oliva, 2016). ERM can be measured, managed and modified to meet the goal of risk management (Behzadi et al., 2018).

The automotive industry uses this model to eliminate the risks as far as possible (Cox, et al, 2018). ERM model is being considered by sector in order to balance risk and manage quality activities. As far as internal risks are concerned the model helps automotive industry to apply prevention and control measures, in the case of external risks such as physical resource like raw materials and finished products, financial such as capital assets and cash inflows, intellectual resource such as workforce skills (Kern et al., 2012). On the other hand, the small arms in the UK also benefitted by the ERM model to handle internal as well as external risks. To cite the risks involved in the case of small arms in the UK such as product risks that means that the failure of production of the small arms and licensing risk (Khan, 2019).

Robson risk management model

Another risk management model to be discussed is the Robson risk management model which too is far efficient to manage risks internal and external for both the automotive industry as well as the small arms industry in the UK (Najjar et al., 2019). In this model, the risks are percept, identified, assessed; strategies are designed and are finally evaluated. In the automotive industry the Robson model is aptly used for risk management (Robson, 2016).

On the contrary, in case of small arms business in UK also effectively uses the Robson model for risk management. The internal risks involved such as production of small guns are managed using the model after following the steps involved in the model process and thus external risks are also managed effectively (Emmanuel-Yusuf et al., 2017). Proper action plans are taken in the model to assess the risks, evaluate them and strategies are planned to solve them in an efficient manner. The model hierarchy is followed, and risk management is performed as per the model.

Channel governance

The concept of channel governance is important for the automotive industry and starts at the manufacturing phase where care is taken and minute details of production are considered (Cao, 2017). Comparatively, small arms trade has proper customer service that helps in the long-term benefits to the industry (Kim et al., 2011). Thus, the governance of the UK small arms industry has various channels and is successful in implementing good sales all over the nation that helps the industry in the long run (Grennan, 2019). In comparison, the industry created and implemented go-to-market strategy and develops different policies including sales process, end customers and type of direct and indirect sales resources that support it (Kim et al., 2011).

Influence of external environment on the supply chain

There are certain elements outside the industry that account to be responsible for the profitability of the automobile industry and are known as environmental factors (Oliveira and Gimeno, 2014). There are various external environmental risks associated with both international automotive industry supply chain and small arms supply chain in the UK that include political factor, economic factor, socio-cultural-factor, technological factor, environmental factor, and legal factor (Smith, 2019).

To start with, the condition of road networks is a reason to worry about the industry as It directly affects the number of vehicle buyers and if the country decides to not invest enough in road networks, obviously people will buy fewer vehicles (Law, 2017). Comparatively, in the case of UK small arms industry fluctuations in the currency is an important risk factor that is required by the management to consider and reduced labour cost is the main area of concern for the sector (Dhanapala et al. 2019). Furthermore, sharing economy of the UK, enhance in the local and low-level crime is also some of the factors affecting the legal distributor of small arms within the UK (Dhanapala et al., 2019). The industry is mainly based on the UK Ministry of Defence and the regulations developed affects the supply chain of the small arms trade (Cox and Atkinson, 2018).

Cultural differences.

The industrialists today are creating issues for themselves by not becoming competent enough to face the competitors (Harwit, 2016). The industry leaders are finding substitutes for the resources which are undesirable and are concerned about getting new customers more than ever before (Cross-cultural Impact on Marketing Strategies: A Study on Automobile Industry, 2014). The reason is their adaptation and acceptance of multicultural environment by hiring top talent to meet the customers’ faith and industries that did not accept this are facing uncertainty in their business hence; a lack of profit (Muhammad et al., 2014). In every firm, the availability of resources determines the companies outcome, however, in some cases the company’s product might not be the preference of the consumer because of their cultural preferences (David et al, 2007). Every nation has different driving pattern, so the design of cars is also different in each nation as per government standards and each nation has different preferences as per culture, so their standards of production are also different (John et al., 2017). It needs to be considered accurately to meet the objective and help to have significant development.

Cultural difference cannot be seen in the small arms industry as it operates within the UK, however, the customer can be different in terms of the purpose as some including military and police purchase weapons legal reasons and some purchase the light weapon for organised crime, and other illicit actions (Smith, 2019).

Conclusion

From the present analysis, it has been inferred that these two-supply chain has forced the industries to adopt different approaches in a quality management system. However, both the industries are somewhere similar in waste management and quality assurance. Along with it, both, automotive supply gain at international level and small arms supply chain in the UK facing supply chain risks such as environmental risk, data integrity and quality risk, political and governmental changes.

Recommendation

The UK small arms supply chain is suggested to recognise the importance of dispersing production and remaining resilient in enhancing the effectiveness of the supply chain. It is also suggested to the small arms to learn from the automotive industry in terms of technological innovation and their responsiveness to emerging technology.

The automotive industry is recommended to implement different model of quality management and risk management with the changing situations and to improve their transportation method so that they can enhance profitability by ensuring its quality.

Both the industries are also recommended to consider risk assessment and management models more thoroughly and should adopt principles and implement in their supply chain effectively to reduce risks and make the operations more cost-effective with maintaining the quality.

References

- Behzadi, G., O’Sullivan, M.J., Olsen, T.L. and Zhang, A. (2018) Agribusiness supply chain risk management: A review of quantitative decision models. Omega.

- Battini, D., Boysen, N. and Emde, S. (2012). Just-in-Time supermarkets for part supply in the automobile industry. Journal of Management Control.

- Blum, J. (2019). Arms production, national defence spending and arms trade: Examining supply and demand. European Journal of Political Economy.

- Brandenburg, M. (2016). Supply chain efficiency, value creation and the economic crisis–An empirical assessment of the European automotive industry 2002–2010. International Journal of Production Economics.

- Brindley, C. (2017). Supply chain risk. Routledge.

- Cao, G. (2017). The influence of external channel environment on channel governance. International Business Research.

- Christopher S. Tang (2006). Robust strategies for mitigating supply chain

- Cox, S.R. and Atkinson, K. (2018). Social Media and the Supply Chain: Improving Risk Detection, Risk Management, and Disruption Recovery.

- Dhanapala, J., Donowaki, M. and Lumpe, L., (2019). Small arms control: Old weapons, new issues. Routledge.

- disruptions, International Journal of Logistics: Research and Applications.

- Dobson, M. and Dobson, D., (2012). Project Risk And Cost Analysis. Place of publication not identified: American Management Association.

- Dou, R., (2013). Proceedings Of 2012 3Rd International Asia Conference On Industrial Engineering And Management Innovation (IEMI2012). Berlin: Springer.

- Elms, D. and Low, P., (2013). Global Value Chains In A Changing World. Geneva: World Trade Organization.

- Emmanuel-Yusuf, D., Morse, S. and Leach, M. (2017). Resilience and livelihoods in supply chains (RELISC): an analytical framework for the development and resilience of the UK wood fuel sector. Sustainability.

- Fan, Y. and Stevenson, M., (2018). A review of supply chain risk management: definition, theory, and research agenda. International Journal of Physical Distribution & Logistics Management.

- Ford, M., (2017). Weapon of choice: small arms and the culture of military innovation. Oxford University Press.

- Gattorna, J., (2017). Reconfiguring the automotive industry supply chain Driving a new focus on customer value. In Strategic Supply Chain Alignment Routledge.

- Giannakis, M. and Papadopoulos, T., (2016). Supply chain sustainability: A risk management approach. International Journal of Production Economics.

- Gobetto, M. (2013). Operations Management In Automotive Industries: From Industrial Strategies To Production Resources Management. Dordrecht: Springer Netherlands.

- Grennan, J., (2019). A corporate culture channel: How increased shareholder governance reduces firm value.

- Gurnani, H., Mehrotra, A. and Ray, S. (2012). Supply Chain Disruptions. London: Springer London.

- Hanson, M., (2017). Arms control. An Introduction to International Relations.

- Hartley, K. and Belin, J. (2019). The Economics Of The Global Defence Industry. 1st ed. Abingdon-on-Thames: Routledge.

- Hartley, K., (2018). Arms industry data: Knowns and unknowns. The Economics of Peace and Security Journal.

- Harwit, E., (2016). China's Automobile Industry: Policies, Problems and Prospects: Policies, Problems and Prospects. Routledge.

- Hult, G., Ketchen, D. and Arrfelt, M., (2007). Strategic supply chain management: Improving performance through a culture of competitiveness and knowledge development. Strategic Management Journal, 28(10).

- International Conference on Business, Law and Corporate Social Responsibility (ICBLCSR'14) Oct 1-2, 2014 Phuket (Thailand), (2014). Cross-cultural Impact on Marketing Strategies: A Study on Automobile Industry.

- Itoh, M., Kato, A., Shimono, Y., Haraguchi, Y. and Taehoon, P. (2018). Automobile Industry Supply Chain In Thailand. Singapore: Springer.

- Itoh, M., Kato, A., Shimono, Y., Haraguchi, Y. and Taehoon, P., 2018. Automobile Industry Supply Chain In Thailand. Singapore: Springer.

- Johnson, P., Flynn, A. and Leenders, M., (2011). Purchasing And Supply Management. New York, NY: McGraw-Hill.

- Johnson, P., Flynn, A. and Leenders, M., (2011). Purchasing And Supply Management. New York, NY: McGraw-Hill.

- Karp, A., (2014). Politics Of Destroying Surplus Small Arms. London: Taylor and Francis.

- Kern, D., Moser, R., Hartmann, E. and Moder, M., (2012). Supply risk management: model development and empirical analysis. International Journal of Physical Distribution & Logistics Management.

- Khan, U., (2019). Arms Trade in Remote Warfare: Pollinating Global Terror. Strife Journal, 10.

- Kim, S., McFarland, R., Kwon, S., Son, S. and Griffith, D., (2011). Understanding Governance Decisions in a Partially Integrated Channel: A Contingent Alignment Framework. Journal of Marketing Research, 48(3).

- Klare, M. (2019). An Overview of the Global Trade in Small Arms and Light Weapons. In Small Arms Control . Routledge.

- Law, C.M. (2017). Restructuring the global automobile industry. Routledge.

- Lieber, K., (2018). War And The Engineers: The Primacy Of Politics Over Technology. New York: Cornell University Press.

- Lo, K.W. (2019). A ballistic model-based method for ranging small arms fire using a single acoustic sensor node. The Journal of the Acoustical Society of America.

- Macola, G. (2018). Weapon of Choice: Small Arms and the Culture of Military Innovation by Matthew Ford. Technology and Culture.

- Macola, G. (2018). Weapon of Choice: Small Arms and the Culture of Military Innovation by Matthew Ford. Technology and Culture.

- Muhammad, N., Scrimgeour, F., Reddy, K. and Abidin, S. (2014). The Impact of Corporate Environmental Performance on Market Risk: The Australian Industry Case. Journal of Business Ethics, 132(2).

- Najjar, M., Small, M.H. and Yasin, M.M. (2019). Adopting and Extending Social Sustainability Practices across the Supply Chain. In Competition Forum (Vol. 17, No. 1). American Society for Competitiveness.

- Oliveira, A. and Gimeno, A. (2014). Managing Supply Chain Networks. Upper Saddle River, NJ: Pearson.

- Pinto, J., Matias, J., Pimentel, C., Garrido Azevedo, S. and Govindan, K., (2018). Just In Time Factory: Implementation Through Lean Manufacturing Tools. New York: Springer.

- Quach, T.N., Thaichon, P. and Jebarajakirthy, C., (2016). Internet service providers' service quality and its effect on customer loyalty of different usage patterns. Journal of Retailing and Consumer services, 29.

- Ramli, N., Mazlan, N., Ando, Y., Leman, Z., Abdan, K., Aziz, A.A. and Sairy, N.A., (2018). Natural fiber for green technology in automotive industry: a brief review. In IOP Conference Series: Materials Science and Engineering (Vol. 368, No. 1,). IOP Publishing.

- Sali, M. and Sahin, E., (2016). Line feeding optimization for Just in Time assembly lines: An application to the automotive industry. International Journal of Production Economics, 174.

- Sarafan, M., Squire, B. and Brandon-Jones, E., (2019). A Behavioural View of Supply Chain Risk Management. In Revisiting Supply Chain Risk. Springer, Cham.

- Seuring, S. and Goldbach, M., 2013. Cost Management In Supply Chains. 4th ed. Heidelberg: Physica-Verlag HD.

- Small Arms Survey (2010): Gangs, Groups, And Guns.. Cambridge [etc.]: Cambridge University Press.

- Smith, C. (2019). Areas of Major Concentration in the Use and Traffic of Small Arms. In Small Arms Control. Routledge.

- Tan, A., (2014). The Global Arms Trade. Abingdon, Oxon: Routledge.

- Terlep, F. (2019). Auto Industry Disruption: Who And What Is Being Disrupted And What To Do About. 1st ed. BookBaby.

- Tilstra, R., (2012). Small Arms For Urban Combat. Jefferson, N.C.: McFarland & Co.

- Welfens, P., (2012). Clusters In Automotive And Information And Communication Technology. Berlin: Springer Berlin Heidelberg.

- Wong, W., (2017). Automotive Global Value Chain. London: Taylor and Francis.

Continue your journey with our comprehensive guide to Supply Chain: Business Excellence.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts