Exploring the Operations Management of Inditex

- 14 Pages

- Published On: 31-05-2024

Introduction

Inditex started as a small retail shop in Spain and developed into a critical player in the fashion industry globally. Currently, the entity has outlets branded as Zara in close to 60 states. Despite the business expanding to foreign countries, there have been a limited number of studies that have been able to investigate the company’s operations process. Thus, this article seeks to fill the existing gap on the current literature on the operations of the company, by highlighting the success and challenges of the company in pursuing their operations management (Chen, Hu, and Song 2017, p. 1271). The study will use an in-depth case approach that uses both primary and secondary sources to highlight the dynamics in Inditex’s management operation process and the subsequent strengths and weaknesses of the same process. Since the company was founded in Spain, some of its annual reports and corporate publications are in Spain, but for this case, the study will strictly use studies published in English. Some of the sources that would be used include annual reports, the company’s publications, and peer-reviewed journals that mainly focus on the theme of operational management of the company. For students and scholars exploring the intricacies of the fashion industry, understanding Inditex's operational strategies can provide valuable insights for their fashion dissertation help.

Brief Overview of the Textile and Clothing Industry

In 2005, the World Trade Organisation incorporation with various regional organizations such as the European Union lifted import quotas that had earlier limited the textile industry; this allowed the industry to access market spaces of all the members of the World Trade Organisation. The increased market space helped in initiating the internationalisation and expansion of various textile companies. The new opportunity allowed Inditex to access multiple occasions such as Germany, India, France, China, and the United Kingdom. It meant that companies had to re-structure their operations from a domestic perspective to an international one. It is at this point that Inditex also changed its operational from a regional company that only operated in some few countries to a global perspective.

Key Areas in Operation

Procurement process

As per the 2018 financial report, Inditex reported that it manufactures 70% of its products. By being independent in terms of its production, the company can control the amount and frequency of newly styled garments. In comparison to other players in the industry, Inditex has the least rate of outsourcing manufacturing supplies. The company has 22 factories that run only in one shift, which creates enough space for the company to respond to argent and unforeseen demands of its products (Ivanov, Tsipoulanidis, and Schönberger, 2019.).

Technological Systems

The company adopted a digital technology that facilitates its information systems and renders it able to have a quick response communication system (Deshmukh and Mohan 2016, p. 20). The technology has also enabled the company to automate various tasks that have allowed it to speed up some jobs, reduced the error rate in the production process, and decrease the cycle time.

Management of Inventory

Inditex has the least inventory in comparison to its competitors, such as the H&M and Gap, among others, judging from its percentage of annual sales. The company avoids manufacturing inventories in any section of its supply chain. Inditex has an optimized model that allows the company to determine the quality and the quantity of products that ought to be delivered in stores, and the consistent delivery of products (twice a week) helps the company’s outlets not to run out of stock (Aftab, Yuanjian, Kabir, and Barua 2018).

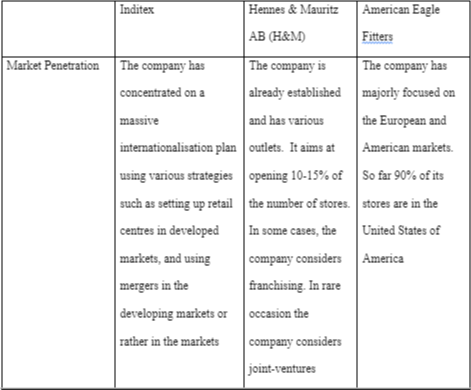

Benchmarking against a strategic group

A benchmarking process on Inditex would be conducted using a model developed by Annarelli and Nonino (2016) the asses operational strategy in terms of market penetration, product development, and diversification. The benchmarking would be done on Hennes & Mauritz AB (H&M) and American Eagle Fitters.

Notes

- Inditex has an aggressive market penetration strategy that has enabled it to penetrate conservative markets as compared to the other two companies. Inditex uses mergers, acquisitions, joint ventures, and franchises to penetrate various markets, while the other two players have concentrated on opening new outlets.

- Inditex should consider diversifying both its markets and products. Currently, it has only focused on the European market and on fashion products, which exposes it to various risks. The same trend has been noted with other players in the fashion industry.

- The company also needs to develop a research and development department that would help it in understanding the needs of the clients in contrast to manufacturing products based on their insights as selling them to clients.

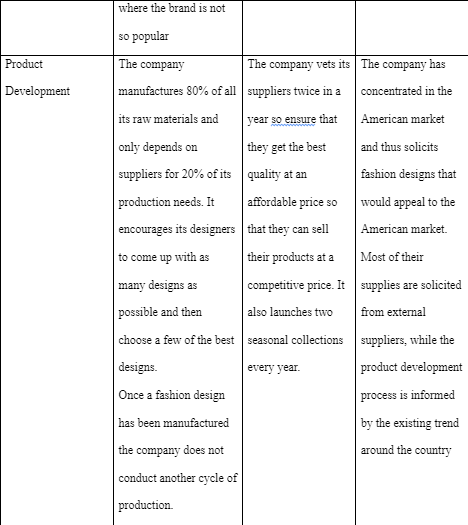

Supply Chain Network Strategy

An effective supply chain is among the factors that have rendered the company efficient, among other operational processes. As per the arguments of Usui, Kotabe, and Murray (2017, p. 17) an efficient supply chain management helps to incorporate all the process that is linked with a bi-directional stream of resources, material, and finance into an organised and coherent means that would help in providing controls and proper oversight. To assess the supply chain of the company, it would be mainly the product design, evaluate the management of logistics, suppliers, and vendors, and evaluate the inventory management system. Figure 1 shows a summary of the process.

These factors are essential because they give Inditex a competitive advantage. The efficient supply chain helps the retailers to deliver the manufactured goods within 24 hours after receiving a purchase order and within 40 hours within various outlets in America and Asia. According to the company’s 2018 financial reports, it has employed close to 6,000 individuals and were able to deliver close to 800 million pieces of clothes in that year (Arrigo 2018, p. 08). Such a competitive environment has enabled the company to improve its operations and therefore enhancing the satisfaction of its clients.

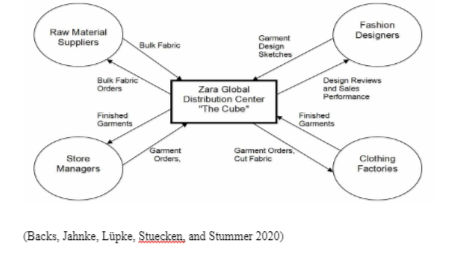

Product Design

The company tries to keep up with the trending fashion and addressing the tastes and preferences of clients by a controlled apparel design process. The process has been dubbed, as ‘Just in Time,’ by the company’s management. The ‘Just in Time’ ideology was adapted from the Japanese philosophy that majorly focused on reducing resource wastage (time and materials) in the process of production. The company has hired various groups of fashion designers that allow it to design all the products by themselves (Alizadeh-Basban and Taleizadeh 2020). The company’s design inspiration is drawn from various sources such as films, trade fairs, catwalk models, and fashion magazines across the globe. According to a publication by Zara (a retail outlet of the Inditex company), out of 4000 designs, the company is likely only to approve 1000 plans. The design number versus the selection criteria depicts the rigorous process of how models have to be vetted to satisfy the needs of the clients from the young to the elderly. Figure 2 shows a brief depiction of the product development and distribution process.

Weaknesses of the operational management

Even though the company has adopted a global outlook, most of its operation has been centred around Europe, which has made it establish more outlets in Europe. As much as the European market is installed and is the primary source of the company’s revenue, it focusses subjects its various regional vulnerabilities within Europe (Tsinonis 2018, p. 107). Factors such as political unrest, natural disasters, and terrorism, or any other occurrence that destabilizes the status quo in Europe can hugely affect the company (Antomarioni, Bevilacqua, Ciarapica, and Marcucci 2017, p. 101). A practical example is a Brexit movement fostered by the United Kingdom, which affected the company’s overall profitability because it majorly focused on the European Union. Besides, the focus on the European market had given the company an outlook as a European-based entity. Thus, it has not been able to penetrate in conservative markets such as in China and other Asian countries.

Conclusion

From the analysis of the operations management of the company, it is clear that Inditex has mainly derived its competitive advantage from its efficacy. The conclusion is justified due to the fact the company does not invest as much capital as its competitors in advertising and public relations activities. Its only appeal is its store design, which can be imitated by other competitors. The fact that the company efficiently delivers its orders at the needed time, keeps it employees motivated, has a digitally-driven manufacturing system, and has a low management inventory has made it a key player in the international market when it comes to the fashion industry.

Continue your exploration of Crisis Management Strategies with our related content.

References

- Aftab, M.A., Yuanjian, Q., Kabir, N., and Barua, Z., 2018. Super responsive supply chain: The case of Spanish fast-fashion retailer Inditex-Zara. International Journal of Business and Management, 13(5), p.212.

- Alizadeh-Basban, N., and Taleizadeh, A.A., 2020. A hybrid circular economy-Game theoretical approach in a dual-channel green supply chain considering the sale’s effort, delivery time, and hybrid remanufacturing. Journal of Cleaner Production, 250, p.119521.

- Annarelli, A. and Nonino, F., 2016. Strategic and operational management of organizational resilience: Current state of research and future directions. Omega, 62, pp.1-18.

- Antomarioni, S., Bevilacqua, M., Ciarapica, F.E., and Marcucci, G., 2017, April. Resilience in the Fashion Industry Supply Chain: State of the Art Literature Review. In Workshop on Business Models and ICT Technologies for the Fashion Supply Chain (pp. 95-108). Springer, Cham.

- Arrigo, E., 2018. Customer relationships and supply chain management in the fast fashion industry. In Diverse methods in customer relationship marketing and management (pp. 1-16). IGI Global.

- Avelar-Sosa, L., García-Alcaraz, J.L. and Maldonado-Macías, A.A., 2019. The Importance of Supply Chains in Global Competitiveness. In Evaluation of Supply Chain Performance (pp. 15-24). Springer, Cham.

- Backs, S., Jahnke, H., Lüpke, L., Stuecken, M. and Stummer, C., 2020. Supply Chain Strategies of the Apparel Industry in Research: A Literature Review. Available at SSRN 3558419.

- Chen, J., Hu, Q. and Song, J.S., 2017. Supply chain models with mutual commitments and implications for social responsibility. Production and Operations Management, 26(7), pp.1268-1283.

- Deshmukh, A.K., and Mohan, A., 2016. Demand chain management: the marketing and supply chain interface redefined. IUP Journal of Supply Chain Management, 13(1), p.20.

- Hannibal, C., and Kauppi, K., 2019. Third-party social sustainability assessment: Is it a multi-tier supply chain solution?. International Journal of Production Economics, 217, pp.78-87.

- Ivanov, D., Tsipoulanidis, A., and Schönberger, J., 2019. Operations and Supply Chain Strategy. In Global Supply Chain and Operations Management (pp. 81-110). Springer, Cham.

- MacCarthy, B.L., Blome, C., Olhager, J., Srai, J.S. and Zhao, X., 2016. Supply chain evolution–theory, concepts and science. International Journal of Operations & Production Management.

- Tsinonis, T., 2018. Inditex Business Activity in Europe. The Review of European Affairs, p.107.

- Usui, T., Kotabe, M., and Murray, J.Y., 2017. A dynamic process of building global supply chain competence by new ventures: The case of Uniqlo. Journal of International Marketing, 25(3), pp.1-20.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts