Manufacturing and Materials

- 9 Pages

- Published On: 13-12-2023

Introduction

In the project planning and investment management, an organisation has to consider several variables to evaluate the profitability and reliability of investment options. As per the case, Widget Ltd. are considering building a new plant to supply a large Original Equipment Manufacturer (OEM). This report applies different tactics of investment appraisals such as net present value, payback period and internal rate of return to select an appropriate investment option from the possible options of Widget 1 and Widget 2. This investigation also examines different elements of manufacturing system and tactics for the selection of a most suitable approach for business dissertation help.

Section 1. Project Appraisal

1.1 Break-Even Analysis

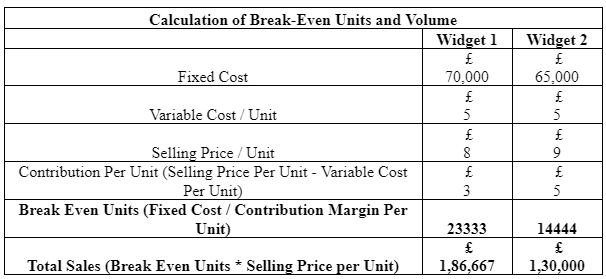

The break-even analysis determines the number of units or amount of revenue that would be needed to cover all business expenditure. In the context of investment planning, it supports companies in mitigation of investment risks and determines revenue targets (Alkaraan, 2017). However, this model could not predict the demand and also ignores the market competition. In the present case of Widget Ltd., the breakeven analysis is carried out below:

1.2 Payback Period

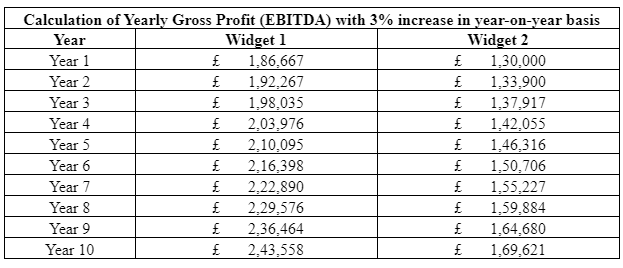

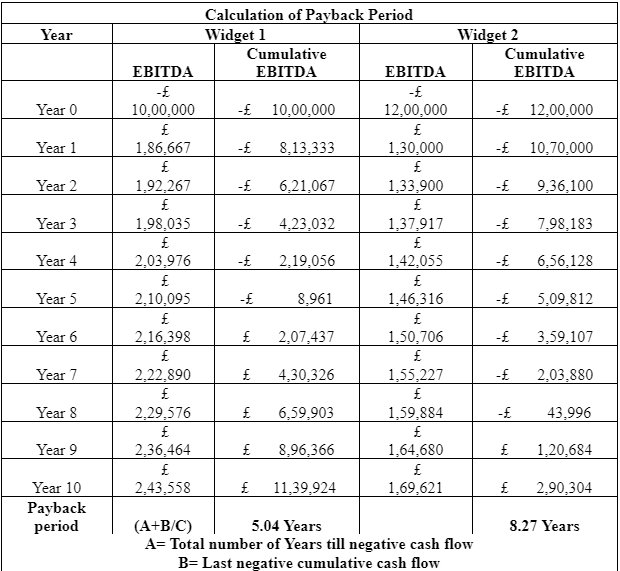

The approach of payback period assists investors in determining the time duration in which whole initial investment could be recovered from an investment proposal. It seems a simple approach. However, this model ignores time value of money in investment planning. Moreover, it also avoids risk factors aligned with future cash flows (Aggarwal and Thakur, 2013).

Dig deeper into Manufacturing with our selection of articles.

As per the above table, the investment in Widget 1 would offer early recovery of initial investment. The payback period of Widget 1 and Widget 2 is respectively 5.04 years and 8.27 years.

1.3 Net Present Value

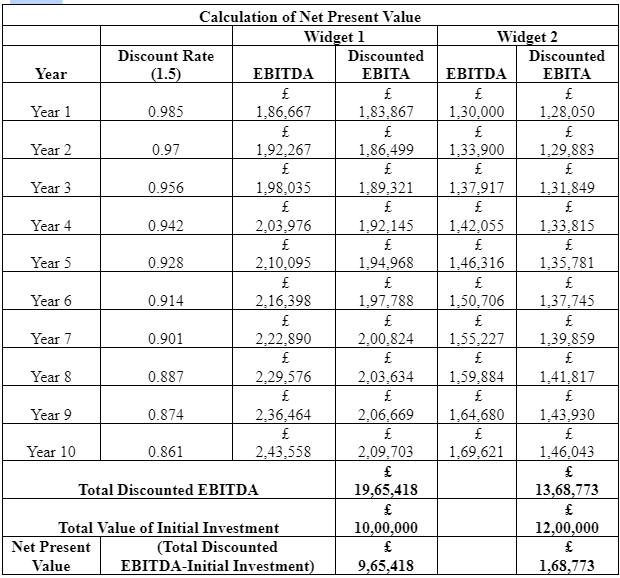

The concept of Net Present Value assists investors to determine whether the investment will increase the firm’s value or not. It uses a certain discount rate to assess future cash flow with consideration of time value of money. However, the reliability of NPV would be affected negatively in the case of improper consideration of cost of capital (Žižlavský, 2014).

As per the above NPV calculation, the investment option of Widget 1 offers the net present value in comparison of Widget 2. Therefore, the Widget 1 would be found more profitable for business entity.

1.4 Internal Rate of Return

Dig deeper into The Fundamentals of Project Planning with our selection of articles.

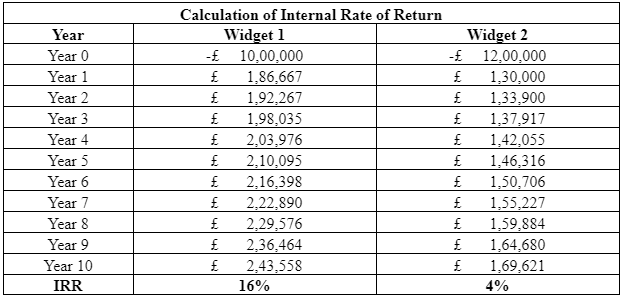

The approach of Internal Rate of Return (IRR) provides a great support in analysing the profitability of investment proposals with consideration of different risk factors in cash flow. However, this tool would not assist in value maximisation decisions (Bierman Jr and Smidt, 2012). Moreover, it requires an appropriate estimation of cost capital to support strategic decisions.

The above table determines that Widget 1 offers higher IRR in comparison of Widget 2. Therefore, the organisation would generate higher returns by managing their investment in Widget 1.

Final Recommendation

As per the outcomes of different tactics of investment appraisal, the management of Widget Ltd should consider the investment option of Widget 1 rather that Widget 2. This is because Widget 1 has determined higher profitability and low payback period.

Section 2. Manufacturing Systems

2.1 Evaluation of Quality Management Approaches and Methodologies

The approach of Total Quality Management (TQM) covers all aspects of manufacturing process such as interest of customers, integration of systems, continuous improvement and effective communication. This approach supports the improvement in the operational efficiency. However, the key drawback of TQM is the need of organisational commitment to quality improvement (Sindhwani and Malhotra, 2017).

Moreover, companies also consider different international standards such as ISO and others. These standards would influence companies to attain the quality management goals. However, this model would not find appropriate when the business entity does not have appropriate monitoring team.

Integrated Management System (IMS) determines standard operating procedures for dealing with various manufacturing tasks (Negahban and Smith, 2014). However, this model would be found very costly for companies because it requires the application of different tools of data analytics.

In the context of present case of Widget Ltd, the approach of TQM should be considered by the management to attain the quality management goals in manufacturing operation.

2.2 Assessment of Supplier Management Approaches

In the context of supplier management process, the concept of Value Mapping assists companies in lowering the business expenditure. In this context, companies consider different variables such as revenue growth, assets utilisation and risk reduction. In this context, companies focus of strong suppliers’ relationship (Priede, 2012). However, this model would offer more benefit in the cost reduction but it would not maintain a significant support in supplier management.

In the supplier management, the single sourcing model assists companies in determining the trust between suppliers and companies. It reduces the risk of opportunistic behaviours. However, this model increases the vulnerability of supply and also increase risk of supply of interruption.

Apart from that, multiple sourcing model reduces the probability of bottlenecks. Furthermore, the high level of competition between suppliers provides negotiation power. On the contrary, companies could find quality issues in the raw material acquisition from the multiple suppliers (Sindhwani and Malhotra, 2017).

In the context of present case of Widget Ltd, the management should consider multiple suppliers to attain distinct business requirements through organisation could reduce the risk of supply chain disruption along with cost control.

2.3 Examining Different Possible Maintenance Approaches

For managing maintenance work in manufacturing units, the corrective maintenance is being termed as an important approach that is applied in detection of anomaly. It requires lower investment. However, it would increase the risk of breakdowns because the faults may lead delay in the production process (Negahban and Smith, 2014).

The preventive maintenance approach influences companies to carry out maintenance work at predetermined intervals and it would reduce the risk of machine failures and emergence of faults. However, it would require a significant investment to manage regular maintenance work.

As per the case of Widget Ltd, the business entity is going to maintain a significant investment in manufacturing operations so as the preventive maintenance approach would support the management in lowering the risk of different faults and breakdowns (Priede, 2012).

Conclusion

As per the above assessment, this investigation concludes the investment in the Widget 1 would play a critical role in enhancing the overall value to business entity along with appropriate level of profitability. This report determines that the organisation should consider the total quality management, multiple sourcing supplier management system and preventive maintenance work to enhance the efficiency of manufacturing operations.

Continue your exploration of Managing sustainable event like glastonbury festival at telfood campus with our related content.

Reference

- Aggarwal, A., and Thakur, G. S. M. (2013). Techniques of performance appraisal-a review. International Journal of Engineering and Advanced Technology (IJEAT), 2(3), 617-621.

- Alkaraan, F. (2017). Strategic investment appraisal: multidisciplinary perspectives. In Advances in Mergers and Acquisitions. Emerald Publishing Limited.

- Bierman Jr, H., and Smidt, S. (2012). The capital budgeting decision: economic analysis of investment projects. Routledge.

- Negahban, A., and Smith, J. S. (2014). Simulation for manufacturing system design and operation: Literature review and analysis. Journal of Manufacturing Systems, 33(2), 241-261.

- Priede, J. (2012). Implementation of quality management system ISO 9001 in the world and its strategic necessity. Procedia-Social and Behavioral Sciences, 58, 1466-1475.

- Sindhwani, R., and Malhotra, V. (2017). A framework to enhance agile manufacturing system. Benchmarking: An International Journal.

- Žižlavský, O. (2014). Net present value approach: method for economic assessment of innovation projects. Procedia-Social and Behavioral Sciences, 156, 506-512.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts