Operational Management in British Petroleum

1.0 Executive Summary

Operation management is the management branch which deals with activities of operation in an organization. This study has made a discussion regarding the operation management prevailing in Gas and oil industry wherein British Petroleum is taken into consideration. The paper has explained the operational issues faced by the company along with executive management tools applied to deal with the problems. This study has also used an information management system and ICT to optimize the operation and further analysed the benefits and challenges of AI for the company.

2.0 Introduction to British petroleum company

British Petroleum is a global oil and gas company which possess headquarter in London, United Kingdom. It is the third-largest energy company in the world, which is calculated by revenues. The main business performed by the company includes exploration, marketing, refining, energy distribution, and alternative energy along with operation in 80 countries. BP has made joint ventures in Asia along with service in Pakistan, Indonesia, China, Malaysia, etc. (BP, 2019). It has also manufactured solar panels and lubricants in India and China, where the wages of labor are cheap. The company has applied a lower carbon energy strategy like solar energy and wind energy to execute its operation. The missions of the company are to lower the price of the fuel but without changing the fundamental qualities, honesty, honest dealing, striving of mutual advantage, and contributing to the progress of humanity. British petroleum has also expressed its importance towards areas like performance, people and capability, external relationship, and lastly, health, safety, and environment (BP, 2016).

3.0 Operations management and quality management strategy of British Petroleum to deal with challenges

British petroleum is one of the biggest petroleum product manufacturers and operates from six continents and possess products and services in 80 countries. It is seen that in the past few years, the country has faced safety and environmental challenges in the operations. However, the company has overcome all issues using precise attention and efforts using sustainable development. British petroleum has its service in various parts of the world with certain terrains and climate conditions, which have led to challenges. The company has used specific sophisticated risk assessment techniques to help in business operations. They have also incorporated environmental management techniques and systems to assist the company in setting priorities for action. The company has attained significant risks that include social and ecological performance. It is stated that there are both external and internal environments of British Petroleum, which leads to issues. The interior climate possesses structures, values, culture and system, resources, and competencies of the company (Maina and Gathenya, 2014). On the other hand, the external environment possesses social, technical, economic, political, government, and legal factors. It is seen that the Gulf of Mexico oil had declined the reputation of BP, which in turn have resulted in long term influence on the ability to attain new opportunity. These created damage in the existing commercial relationship with partners and host governments and have led to the massive burden of cash. Moreover, it also reviewed that the operating costs have enhanced over the past 10 years and have continued to increase independent of the fluctuation of the oil price (Rushton, 2014).

It is revealed that the present strategy of British Petroleum and its operations have revolved around significant areas that include health, security, environment, and safety; employees; government and communities; business partners; and company assets and financial integrity. The company is working on lower-carbon future initiatives, which include energy efficiency, which provides for the price of carbon in investment decisions (Top250.platts.com. 2015). The company has also promoted the pathways for lower costs energy, and the company has also continued to invest in alternative energy. Since the company aims to reduce the emission of carbon, so significant attention is provided towards biofuels, wind, solar, and carbon captures. British petroleum has also focused on exploration and production. It is growing values for long-term growth to build a portfolio and ensure the positions around the world for crucial hydrocarbon (Maull, Brown & Cliffe, 2001). The company also focuses on refining and marketing, which have to hold a portfolio of quality, integrated, and access market growth and concentrate on attaining safe and compliant operations. After attaining more significant issues while operating, it is stated that the company has applied various changes in the attitude towards different interest groups. It is reviewed that role of government has altered under the impact of political influence and instability (Rushton, 2014). The government of oil-producing country and suppliers have arrived to be convincing. At the present status, British Petroleum had to establish a more stable long-term relationship with the government to avoid the risk. The company has also strengthened safety, compliance, and risk management to stay safe from any sorts of future issues. In addition to that, the company has also applied quality management strategies wherein employee training and involvement of employees had also been performed to enhance the operational performance. Preparation and participation of employees have also arrived as the ways to improve the performance of operation (Christopher, 2011). The application of quality management strategy gave not only increased profits but have helped in declining costs and enhanced productivity and market share. In addition to that, it is also stated that since there is the involvement of the government to review the quality standards of petroleum products, the company had faced significant issues due to a lack of quality management practices. However, after British Petroleum has applied different approaches like six sigma concepts, Benchmarking, and ISO 9000 standards certifications, the company is working effectively as unhappy customers lead to quality issues. It can be stated that a practical application of quality management and operation management strategies has helped the company to attain an excellent reputation within its customers and suppliers (Hasini, 2008). Since, in the future context, all the stakeholders will prefer to make relations with those companies who apply sustainability approaches and manage operation effectively. Thus, the application of operation management and quality standards by British petroleum has helped these companies to meet the standards and deal with the challenges associated with operations and quality.

4.0 Tools operational management to specifically contribute to achieving organizational objectives and competitiveness of British petroleum

Operation management tools are essential to possess excellent performance as an operations manager. British petroleum applies tools to overhaul and enhance the operation within the organization. The operation managers of British oil have also implemented these tools to eliminate the errors and defects prevailing during the process of service and reduce the costs of production. The application of the operation tool has assisted British petroleum in having internal administration and organization structures that have had helped in the smooth function of the business. Operational management tools also support quality control in British petroleum to conduct the measurable results and track the goals of the company (New Orlean Sun, 2014). Lean manufacturing and Just-in-time have been employed by British Petroleum and are explained below. Due to an increase in the challenges faced by the oil and gas industry, these sectors have started applying modern innovative technology and business methodologies. British petroleum has also adopted lean manufacturing to maximize the values for customers and decline the needed resources. The company has taken lean manufacturing to reduce defects in products and services and eliminate wastage (Brennan, 2013). The company gathers the information on the present process, analyses the working principles of work, and later acknowledges the defects and waste. Lean manufacturing is also found to provide methods to implement change, which results in improvement. British petroleum has attained continuous growth due to the effective change made by the lean manufacturing process. After the company has started to apply thin, they can break things into smaller and simpler parts and even bring improvements (Mei, Mile & Danny, 2016). Lean has also helped the British petroleum company finds defects and wastage and analyses the effectiveness of the equipment and find the issues of transportation along with production operations. Just-in-time (JIT), which is one of the inventory management methods, is used in the oil and gas industry. British Petroleum has also adopted JIT to deliver the supplies and control the inventory. It has also helped the company to minimize the more critical raw material’s stock and even hazards which arrive with the list. The company has applied JIT to enhance productivity, attain quality, reduce costs, and attain delivery time effectively to remove all waste present in the process of manufacturing of petroleum. JIT has assisted British Petroleum to submit its projects on time and as per the requirement of the clients (Brennan, 2013).

5.0 Information Management System and ICT role in Operations optimization in British Petroleum

The use of an information management system is gradually gaining importance in the oil and gas industry. Companies such as British Petroleum are increasingly focusing on the adoption of information management to reap the advantages and benefits offered by the information management system. The application of the information management system in British Petroleum is anticipated to play a critical role in enhancing the conventional, unconventional as well as midstream operation of the company. Accordingly, the adoption of the information management system is ascertained to have the potential to influence the exploration cost as well as the production revenue. At the same time, the use of the information management system in the company has the potential to make the data collection easier. In contrast, the use of cloud storage makes it simpler for the company to store the bulk of data (Beckwith, 2011). The use of an information management system is ascertained to improve analytical activities, which can lead to greater operational efficiency. In this regard, the use of advanced information management techniques such as real-time analytics and predictive analytics solutions can play an essential role in enhancing the ability of the company to analyse the various set of data such as seismic and micro-seismic data, which can positively contribute in the reducing drilling time as well as it can lead to drilling safety (Mohammadpoor & Torabi, 2018). The application of ICT has been increasingly significant importance across different sectors and industries due to various advantages that bring to the companies. As a result of which the companies such as British petroleum in the oil and gas industry have also begun to lay considerable attention to the application of ICT. Accordingly, the use of ICT in the company is anticipated to help in the optimization of its upstream operations that include exploration and production as well as the downstream service involving transportation, refining, and distribution (Anagnostopoulos, 2018). The application of the ICT in the British Petroleum has the potential to facilitate in real-time monitoring of oil exploration activity, and the data generated can be analysed by the company to reduce any potential risks and optimize the drilling performance as shown in figure 1.0:

Also, ICT can be used by the company to monitor the oil fields remotely using a smart, collaborative environment, as depicted in figure 2.0. Accordingly, the use of software can be used by the company to support decision making as well as for achieving collaboration. The smart, collaborative environment can facilitate the optimal use of resources leading to operation optimization within the company.

The operational strategies involving the use of ICT applications within British Petroleum have significantly contributed to attaining a more significant competitive advantage. In this regard, its form of ICT allowed the company to modernize its production capacity as well as increase their operational flexibility for enhanced competitiveness of the company. At the same time, the use of ICT has also increased the ability of the company to comply with the environmental changes. The use of modern ICT solutions has contributed to delivering service is a fast and convenient way (Porssaa & Mirzazadeh, 2016). Additionally, the use of ICT has dramatically increased its supply chain management activities, which has served as an essential source of its competitive advantage.

6.0 Benefits and challenges of AI for British Petroleum

In recent times, the use of AI in the oil and gas industry is growing with the advancement in new and advanced technologies. Accordingly, British Petroleum has demonstrated its increased focus on the use of AI for improving its operational efficiency. In other words, the increasing use of AI in the company is anticipated to play an essential role in maximizing and optimizing its revenue and operational efficiency in both domestic and global contexts. In this regard, the leveraging the potential of AI in the upstream operation such as to drill and mine hydrocarbons and other materials to produce oil can be argued to enhance its operational efficiency significantly. Notably, the use of AI can provide the company with accurate intelligence and data regarding drill and exploration on land and water, which has the potential to seek precession in drilling and help minimize the risks such as fires and oil spills. At the same time, the use of robots with AI capabilities for the exploration of hydrocarbons can significantly help the company to enhance its productivity while reducing the cost of operation and risk involved to the worker (Sennaar, 2019). Moreover, oil reservoir management is an essential component of operation management in the oil and gas industry, and it involves a range of technicalities seismic interpretations and management of reservoir and geology, among others. These activities require regular maintenance and surveillance, which is often costly. However, the application of AI systems that are trained with data related to these technicalities can be argued to significantly help British Petroleum in its operations such as surveillance, reservoir engineering. It can also reduce the overall maintenance cost for it. In the similar context, the use of AI-powered chatbots has the potential to facilitate better interactions with its customers as well as it can play an essential role in resolving customer’s queries, which can save time and cost for the company and positively contribute in improving its business operation in domestic as well as the global environment. Nonetheless, there are specific challenges that the company may face in the implementation of the AI solution. In this regard, one of the significant challenges that the company may face is the cost associated with the development and implementation of AI solutions. Accordingly, AI is still evolving and is widespread use is still limited, which makes its implementation cost relatively high. Another major challenge is related to the availability of skilled and competent employees that have an adequate understanding of the use of the AI system. Notably, it has been observed that there lack experienced individuals and experts within the company essential, ensuring maximum utilization of the AI system.

7.0 Conclusion & Recommendations

In conclusion, it has been noted that British Petroleum develops efficient operations management processes & quality management processes, which has helped it to achieve its organization’s strategic management objectives. In this regard, the organization is ascertained to involve in the use of different operational management tools that has further added to its operational effectiveness and competitiveness. At the same time, it has been analyzed that the application of information management systems and ICT, along with AI, has significant potential to optimize its operational efficiency and contribution to its success in both domestic and global environments. However, it has been noted that there still are some areas of improvement that the organization needs to focus on, particularly in the context of ICT and AI. Correspondingly, the section below provides some useful recommendations that the organization needs to focus on its future growth and success. Lack of skilled personnel and the cost of implementation of AI and ICT represent a considerable challenge for the organization. In this regard, it has been suggested to the organization to focus on generating awareness about the benefits of AI and ICT and design training of its employees, including its executives, to familiarise with the ICT and AI (Mohammadpoor & Torabi, 2018). Also, the application of AI and ICT in the organization is at an early stage. To reap the benefits of these technologies, it has been suggested to the organization to develop collaboration with the AI and ICT experts and vendors such as IBM to leverage their knowledge and expertise to achieve operational excellency (Mohammadpoor & Torabi, 2018).

Assignment Task - 2:

1.0 Project Network Diagram

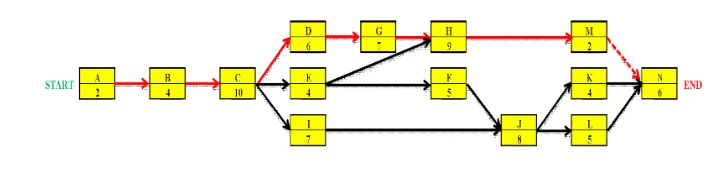

Preparing a network diagram is considered as an essential element for a construction project manager. Hence, the construction project manager needs to make a network diagram for graphically illustrating the major construction activities. Also, preparation of the network diagram for significant events of the construction project before the actual commencement of the project helps the project managers to develop a comprehensive understanding of the vital activities to be executed to complete the assigned construction project with the estimated time and schedule (Verma 2012). Notwithstanding, figure 3.0 below illustrates the project network diagram of the major phases and activities that the ABC Construction Group will complete the construction of a new manufacturing plant.

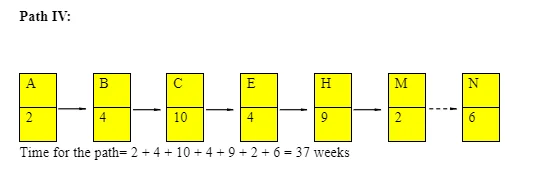

In figure 3.0 of the project network diagram, each node (boxes) represents an activity and is duly labeled with the activity abbreviation and the associated completion time. Accordingly, considering the above network diagram, beginning with the start note and stopping with the end node, six paths for the given project has been identified. These paths are:

Comparing the times of the six paths illustrated above, the maximum {46, 43, 44, 37, 41, 42} = 46. This signifies that the Path I take the maximum time, which is estimated to be 46 weeks. It is thus the Path I is the critical path, as shown in the above diagram with the red arrows.

2.0 Project Schedule with PERT/CPM

Calculation of forwarding Pass, Backward Pass, and Slack/Float

To determine the project schedule for the new manufacturing plant with PERT/CPM, it is first essential to calculate forward pass (earliest start, earliest finish), backward pass (latest start, latest finish) and slack or float time for each activity. Table 2.0 illustrated below shows the result of the calculation forward pass, backward pass, and slack/float of the listed activities A, B, C, D, E, F, G, H, I, J, K, L, M, N.

Based on the calculation of the forward pass, backward pass, and slack/float as shown in table 2.0 above, schedule of the whole project with PERT/CPM has been illustrated in figure 4.0 below:

Notes

a) The earliest start (ES) is the most initial time that an activity can commence based on logical constraints.

b) Duration (D) is the estimated time to carry out the operation.

c) Early Finish (EF) is the most initial time that an activity can be finish based on logical constraints.

d) Activity (A) is the abbreviation of the events to be performed by the company.

e) Latest Start (LS) is the latest time than an activity can commence according to logical constraints and without delaying the overall project.

f) New Finish (LF) The latest time that a business can finish based on the logical constraints and without delaying the total project duration.

g) Slack/Float (F) is the time that an activity can suspend without disturbing the overall project duration (Engwall, 2012).

As noted above that the estimated project completion time for the new manufacturing plant is computed as 46 weeks if no delays occur, which is a week earlier than the estimated deadline of 47 weeks, after which the ABC Construction Group is liable for the penalty. Notably, this calculation depicts that if all the activities of the ABC Construction Group take the same as the expected, the minimum time for the completion of the construction project activities is 46 weeks. Given the minimum time for the project completion, it can be argued that it is challenging for the company to complete the project within 40 weeks. It is worth mentioning that the above calculations have been performed considering that the company has sufficient resources to carry out the activities. In the table above, the last column presents the estimation of slack also float time, which is the amount of time that an event can be delayed without affecting the overall project completion time. In this context, it can be identified from the above-presented table that for activities A, B, C, D, G, H, M, N, the slack/float time is zero, which signifies that these activities critical activities and they cannot be delayed. Notably, any delay in these project activities can lead to the extension of the project completion time. Hence for these activities, the project managers must avoid any delays to prevent delaying project completion. On the other hand, E, F, I, J, K, L are noted to be non-critical activities. In this regard, the slack/float time actions E, F, J, L are also computed as 1 week for each of these activities. This signifies that even if the E, F, J, L activities are delayed by 1 week each, it has no significant impact on the completion of the project and delay of 1 week can be tolerated for other activities, without delaying project completion. Similarly, the slack time for activities I, K, has been estimated as 3 weeks, which implies that even if these two activities are delayed by 3 weeks each, it rarely has any significant implications the ABC Construction company ability to complete the project within the specified deadline of 47 weeks. In other words, delay of these two activities up to 3 weeks can be tolerated for other activities, without delaying project completion.

References

Anagnostopoulos, A., 2018. Big Data Techniques for Ship Performance Study. International Society of Offshore and Polar Engineers, pp. 887-897.

Christopher, M., 2011. Logistics and Supply Chain Management (4th ed.). Edinburgh: Pearson Education Limited.4.

Engwall, M., 2012. PERT, Polaris, and the realities of project execution. International Journal of Managing Projects in Business, Vol. 5, No. 4, pp.595-616.

Hasini, E., 2008. Supply Chain Optimization: Current Practices and Overview of Emerging Research Opportunities. Information System and Operation Research, Vol. No. 42, No. 2, pp. 93-96.9.

Maina, C. and Gathenya, J., 2014. Influence of Economic Factors on Performance of Project Management among Petroleum Marketing Firms in Kenya. International Journal of Academic Research in Business and Social Sciences, Vol. No. 4, No. 6, ISSN: 2222-6990.

Mei, F., Mile, T., & Danny, S., 2016. Relationship of ISO 9001:2000 quality system certification with operational and business performance. Journal of manufacturing tech. management, Vol. No. 19, No. 1, pp. 22-37.

Mohammadpoor, M. & Torabi, F., 2018. Big Data analytics in oil and gas industry: An emerging trend. Petroleum, pp. 1-8.

Porssa, A. & Mirzazadeh, H., 2016. Develop an Information Technology Model to Improve Customer Service in NIGCS. Procedia - Social and Behavioural Sciences, Vol. 229, pp. 167 – 174.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts