Supplier Management and Supply Chain Efficiency at Wal-Mart: Procedures, Technology, and Systems for Cost Savings and Reduced Waste.

Introduction

The chosen organization for this research paper is Wal-Mart. Talking about the supplier management in this research; the reference should be made to procedures, technology, and systems connecting the customer with a supplier. The performing and efficient supply chain provides a helping hand to the business saving money. This can be done through the better inventory system, shorter processing time of the factory, and faster client deliveries. In turn, this can result in reduction of decay and spoilage, which is crucial for those seeking business dissertation help.

Continue your exploration of Efficiency with our related content.

Research questions

Research question 1:

How flexible is Internal and External process Maps of Wal-Mart?

Research question 2

Does Five Operations Performance Objectives explains the supply chain strategies of Wal-Mart?

Literature Review

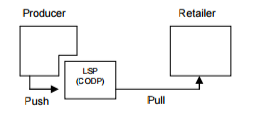

Bloomberg et al. (2002) argues that the logistics service providers are external party that manages, controls, and delivers the activities related to the logistics on the client’s behalf. The LSP performs activities ranging from logistics services which are operational and basic, such as transportation, to strategic and sophisticated logistics services, such as Supple Chain Management. The relationship existing between the customers and the LSPs have seen growth over time from a view which is contract focused to partnerships. This relationship is beneficial to both the client and the LSP.

The LSP, therefore, can be bridging the gap between the links held successively within the supply chain. However, importance lies with regards to the party that is served by the LSP. The delivering party has the most upward position in the chain (Langley and Holcomb 1992). The wide range of logistics activities is taken care by the LSP. For example, the goods’ transportation and the activities related to the warehousing, where there is inclusion of in and outbound processes.

These performances of these activities in relation to the nature of work are determined by the direction that the flows of goods take. The implication of these has been the clear distinction needed between the outgoing flow of goods to the receiver from the LSP and the incoming goods coming from the delivering party. The application of the incoming goods gets the push to the warehouses of the LSPs. The application of the outgoing goods has been the opposite. The flow of outgoing goods is based mainly on the pull principle (Luo et al. 2001). For instance, the optimal batch sizes produced by the manufacturers push the finished products’ inventory to the LSP from the factory. There is subsequent obligation of the LSP in taking care of the customer specific supply orders to the manufacturers (for example wholesalers/retailers). The implication of this has been the Customer Order Decoupling Point (CODP) that has the placement at the LSP position in the supply chain.

The subdivision of the inbound process can be done into three primary processes: checking, receiving, and the goods’ internal transportation.

After receiving of the goods, there is movement of the goods to the processes of checking. Through this process, there is verification of the quantities in checking whether a match exists between the actual shipment and shipment documentation. Next to it, there is performance of the quality checks done randomly. In the Warehouse Management System (WMS), there is documentation of the quality checks, item verification, and the information related to the contents and arrival time. The process is also inclusive of goods’ status, fast moving or slow moving, making a decision related to the location either between the forward or the reserve area (Manrodt and Davis 1993). The aims of the sub processes are the rework’s early detection or the needs of repackaging as well as the arrival of the right quantities of the right goods that are without defects.

The internal transportation, in the last stage, prepares the storage of the quantities. In storing the goods, there is adaptation of the quantities to the modules of the internal storage if the modules of the external storage are different from the modules of the internal storage. The finishing is done by the processes with the quantities’ inbound transportation to the storage area location. Here, easy picking can be done with its transportation to the next stage. Novack et.al. (1992) has been dividing the storage area to two parts. The first part is the reserve area, where the products that are slow moving and have their storage in the most economical way. The second part is the forward area, the storage of the fast moving products takes place for easy retrieval. The aim of the sub process is to get the goods’ storage right the first time that avoids the relocation.

Within the supply chain, the outbound logistics plays a vital role in the process of supplier’s CRM (Customer relationship management). The definition of the outbound logistics can outline the processes that have relation to the storage and movement of the products to the end use from the production line’s end (Schmenner 1995). Most of the retailers that includes Target and Wal-Mart put stringent standards of product delivery to their suppliers. A supplier’s failure in providing reliable service delivery to its retail customers can be resulting into delisting or financial penalties of the products of the suppliers from active product portfolio of the retailer. Therefore, performance of the outbound logistics is the representative of the main factor related to the decision of the retailer of whether or not it would be stocking the products of the supplier.

Methodology

Primary research

The primary research is dependent on a number of elements such as, observation, interviews, questionnaire and discussion with the groups in finding out the supply chain operations and logistics in Wal-Mart that illustrates the external and internal process map(s) and operations of the organization in terms of supply chain strategies. The primary research is carried out with the questionnaire form in this report, where the sending and the filling of the questionnaire are done online with the respondents drawn from the employees of Wal-Mart (Diaz Ruiz 2013)

Objective

The objective is to measure the operations of the supply chain and the logistics of Wal-Mart along with the illustrations of external and internal processes with the usage of Five Operations Performance Objectives.

Methods

The method used in this research to collect data is with self-enumeration. With this method, questionnaire is sent to the chosen sample, where the respondents fill the questionnaire without the interviewer’s assistance. The questionnaire is sent electronically via internet (Bradley 2010).

Questionnaire designs

The questionnaire is prepared keeping in mind the objective of the survey. In this survey, personal questions will not be asked except the age and gender. The researcher will ensure that the confidentiality is maintained with regards to the information and in the near future, the information will be destroyed.

The process of designing the questionnaire will also include the following steps.

- Data users are consulted

- Previous questionnaires are reviewed

- Questionnaires are drafted

- Questionnaires are revised and reviewed

- Finalization of the questionnaires

The questionnaire will contain 9 questions in analyzing the research questions. The questions are almost equally split between close ended and open ended questions that represent quantitative as well as qualitative research (Bradley 2010).

Sample designs

The stratified sampling is carried out with strata or the mutually exclusive groups such as involving both gender in the department of logistics and supply chain of Wal-Mart (Bradley 2010).

Sample size

The sample size is 50 respondents. The respondents include participants in the age group of 18-65.

Secondary Research

Objective

The secondary along with the primary research is carried out for the following objectives:

- Accessing quick, low cost and easy knowledge

- Helping align the focus pertaining to the primary research in large scale for identifying the answer

- Ruling out the project proposals which are potentially irrelevant

Use of techniques

There are four steps that have been involved in this secondary research:

- Identification of the domain of the subject from where information is acquired

- Existing data is gathered

- Comparison of the data that emanated from various sources

- Data analysis

Results and discussion

Internal and External process Maps

In Wal-Mart, the flow process deals is related to logistics with respect to the products making and the establishment of the logistical flexibility required for serving the target markets. The process is inclusive of all necessary activities to manage the flow of the product with the logistical facilities to obtain, implement, and manage flexibility (Berry and Cooper 1999).

The Strategic Process

At the strategic level, the strategic process’ objective of Wal-Mart in relation to the logistical flow is determining of the infrastructure of logistics required to fulfill the wants and needs of the customers. At the beginning of the process, the team reviews the business strategies that are functional for manufacturing, logistics, marketing, and purchasing. The requirement of this sub process interfaces with the CRM, where reviewing is done on marketing and corporate strategies. These strategies provide a helping hand in identifying the changes and expertise in the logistics technology required in operationalizing the manufacturing flow in the organization (Zinn and Bowersox 1988). The incompatibility between the market characteristics and the manufacturing process can lead to business performance’s unfavorable impact in Wal-Mart. At the same time, the manufacturing’s environmental aspect set out by the environmental laws, corporate strategy, and business plan must be taken into consideration. There is link between the manufacturing strategy and the corporate strategy as the practices of the environmental management may be strengthening the competitive advantage of the company.

The second sub process’ objective in Wal-Mart is determining the magnitude of the manufacturing flexibility required by the supply chain and the firm. The provision of this sub process with respect to the constraints and the capabilities of manufacturing, such as minimum cycle time and batch size, have the requirement of the labor expertise for the quality controls and the policy. The commercialization and the product development along with the order fulfillment has the provision of input to this sub processes. The team of Wal-Mart provides the definition of buy/make strategies (Graves and Willems 2000). For instance, the manufacturing activities are considered as strategic with no scope of outsourcing at any cost. The provision of these strategies is indicative of supplier relationship management regarding the selection of supplier and the eventual guidance of opportunities in relation to partnership. The sub process’ last activity is characterized by the capacity growth on team plans based on the business plan and marketing strategy.

The extent of the flexibility has its establishment in the previous sub process leading to the determining of the push-pull boundaries. The customer service goals and the customer tolerance time can be constraining the extent of the postponement of the manufacturing in the supply chain. The next sub process’ objective is identifying the constraints of manufacturing and the requirements in helping determining the supply chain capacities. The role of the supplier development strategy and the suppliers is this sub process’ key component to define the synchronization of the extent of the supply chain’s activities.

The next sub process is characterized by the team determining the capabilities of manufacturing and translating them into the customer deliverables. For instance, the minimum lot size that is economically viable and the minimum cycle time has been the result of the company’s logistic capability design. Making the strategy effective, there must be communication and the understanding of it across the organization (Boyer and McDermott 1999). In the final sub process, there is development of the team with respect to the metrics framework and the communication of the same to the management team of the customer relationship. The measurement of these metrics includes the logistics flow process’ effectiveness that is inclusive of product quality, inventory levels, and cycle time.

Operation in terms of supply chain strategies

The management objectives and the broad stakeholder objectives with regards to Wal-Mart in the context of the strategic operations, needs to be defined on the grounds of day to day operations. There have been five performance objectives that are be mentioned.

Quality: right things should be done in satisfying customers. One of the major customer satisfaction factors is quality. Quality indicates the production of products or services to be consistent. The dependability is increased and the costs are reduced because of the quality.

Speed: the value to the customer is increased because of speed. The importance of speed involves the reduction of risks (shortened forecasting times) and reduction of inventory (Vollmann 1997).

Dependability: the establishment of dependability is over time and this factor has the overriding effect on all other factors. It does not matter how innovative, fast, or cheap the product or the service is, if the dependability of the product/service to the customer is lacking in terms of quality and timely delivery. In that case, the customer will be lost. The organizational dependability in Wal-Mart is very important because of the saving of money and time and thereby reducing the ineffective use of resources and time. The dependability provides the organizational stability as operational quality is affected by the disruptions and the time going beyond the costs (Dyer et al. 1998).

Flexibility: ability of changing in how, what or when that enables the company in providing four types of requirement.

- Service/product flexibility: operational ability in introducing modified or new services/products

- Mix flexibility: ability of producing mixed or wide variety of services/products

- Volume flexibility: ability of changing output level

- Delivery flexibility: ability of changing delivery time

There is also importance of flexibility within the organization because the response to change is speeded up maintaining dependability and saving time (Lambert et al. 1998)

Mass customization; the production of the customized products or service should be at a high volume in keeping down the costs. For instance, Apple introduced flexibility in its designing providing the customers the ability in designing their products, although within limits.

Agility: This is the combination of the objectives of all operations, although its focus is specific on flexibility and speed. The supply chain and the operations’ ability can provide response to the market uncertainty.

Costs: the costs is attempted to be kept low by every organization. The measurement of costs can be by productivity. In calculating productivity, there are few formulae:

P = output/input

Single factor P = Output/one input

Multi-factor P = Output/all inputs

The leaders of the companies prioritize projects for the reduction of logistics and inventory expenses. Over the short run, this can help, although, ignoring the long term can evoke professional risks. The strategies must be effective along with the plan which is well defined and right tools helping the alleviation of the pressure in the current time and would be readying the managers for the changes in the market in the future (Cooper et al. 1997).

Recommendations: Improvements in logistics and supply chain management

The Wal-Mart’s performance can be improved in the following ways.

Improvement in the distribution network

The distribution network of a company can be dubbed as the operational hinge one should be building around. Everything is affected by distribution from tracking of the delivery to the sales strategy. The primary goal is the improvement of a company’s distribution network, which can be done with a cluster view or holistic approach. With regards to the holistic approach, the essential parts are reviewed in the company’s distribution network in figuring out the way the parts would be working in sync.

Devising distribution strategy

The integral part of the effective supplier management framework is the distribution strategy. A better idea can be obtained through it regarding what it takes in shortening delivery times, improvement in the customer service, and reduction of goods’ decay. The seeds of financial stability over the long run can be planted by a company with the help of supplier chain management’s broader field and supplier management.

Monitoring cash flow

The monitoring of the cash flow is a fundamental tool used by a number of organizations in improving the supplier management. There is importance in tracking terms and conditions of the payment with various groups within the supply chain that forges an effective plan in understanding the use of the technologies for the monetary transfers.

Establishing information conduit

The information conduits are the businesses of channels with its usage in sharing key data, such as information tracking with the important partners. In establishing the information conduits, proper and prompt distribution of data must be ensured related to the company.

Tracking inventory

The inventory of the organization can be tracked with the designing of the internal spreadsheet or with tracking software. This will show the amount of products that a company has, the amount it needs, or if things such as, theft, decay, damage etc happens to the product.

Conclusion

The logistics’ bias of Wal-Mart in relation to the process analysis can result in considerable gap, particularly in the industries whose dominant function is supply chain and logistics. The matter should be dealt with more comprehensive approach. The development of more generalized typology can be encompassing the firm’s logistical operations that have the engagement in the provision of services. There is increasing recognition with respect to the supply chain management as the key business processes’ management of Wal-Mart across the organizational network that consists the supply chain. There should be considerations of the processes to be imbibed, the activities and the sub processes that each process contains, and the way interaction takes place among each other in the processes and with the silos of traditional functions.

Continue your journey with our comprehensive guide to Success in the international marketplace.

References

- Berry, W. L. and Cooper, M. C. (1999) ‘Manufacturing Flexibility: Methods for Measuring the Impact of Product Variety on Performance in Process Industries,’ Journal of Operations Management, Vol. 17, No. 2, p.177.

- Bloomberg, D. J., LeMay, S. and Hanna, J. B. (2002) Logistics. Prentice Hall, Upper Saddle River, NJ.

- Boyer, K. K. and McDermott, C. (1999) ‘Strategic Consensus in Operations Strategy,’ Journal of Operations Management, Vol. 17, No. 3, pp. 289-305.

- Bradley, N. (2010) Marketing Research. Tools and Techniques, Oxford University Press, Oxford.

- Business Logistics, 13(2), 1.

- Cooper, M. C., Lambert, D. M. and Pagh, J. D. (1997) ‘Supply Chain Management: More than a New Name for Logistics,’ The International Journal of Logistics Management, Vol. 8, No. 1, pp. 1-14.

- Diaz Ruiz, C. A. (2013) ‘Assembling Market Representations’, Marketing Theory, 13 (3): 245–261.

- Dyer, J. H., Cho, D. S. and Chu, W. (1998) ‘Strategic Supplier Segmentation: The Next “Best Practice” in Supply Chain Management,’ California Management Review, Vol. 40, No. 2 (1998), pp. 57-77.

- Graves, S. C. and Willems, S. P. (2000) ‘Optimizing Strategic Safety Stock Placement in Supply Chains,’ Manufacturing and Service Operations Management, Vol. 2,No. 1, pp. 68-83.

- Helms, M. M., Ettkin, L. P. and Chapman, S. (2000) ‘Supply Chain Forecasting - Collaborative Forecasting Supports Supply Chain Management,’ Business Process Management Journal, Vol. 6, No. 5 (2000), p. 392.

- Lambert, D. M., Cooper, M.C. and Pagh, J. D. (1998) ‘Supply Chain Management: implementation Issues and Research Opportunities,’ The International Journal of Logistics Management, Vol. 9, No.2 (1998), p. 1.

- Langley, C. J. and Holcomb, M.C. (1992) ‘Creating logistics customer value’, Journal of

- Luo, W., van Hoek, R. I. and Roos, H. H. (2001) ‘Cross-cultural logistics research: A literature review and propositions’, International Journal of Logistics: Research and Applications, 4(1), 57-78.

- Manrodt, K. B. and Davis, F.W. (1993) ‘The evolution to service response logistics’, International Journal of Physical Distribution & Logistics Management, 23(5), 56.

- Novack, R. A. and Simco, S. W. (1991) ‘The Industrial Procurement Process: A Supply Chain Perspective,’ Journal of Business Logistics, Vol. 12, No. 1, p. 145.

- Novack, R. A., Rinehart, L. M. and Wells, M. V. (1992) ‘Rethinking concept foundations in logistics management’, Journal of Business Logistics, 13(2), 233.

- Pohlen, L. (2001) ‘Supply Chain Metrics,’ The International Journal of Logistics Management, Vol. 12, No. 1 (2001), pp. 1-19.

- Schmenner, R. W. (1995) Service Operations Management, Prentice Hall, Englewood Cliffs, N.J.

- Vollmann, T. E., Berry, W. L. and Whybark, D. C. (1997) Manufacturing Planning and Control Systems, New York, NY: Irwin/McGraw-Hill.

- Zinn, W. and Bowersox, D. J. (1988) ‘Planning Physical Distribution with the Principle of Postponement,’ Journal of Business Logistics, Vol. 9, No. 2, pp. 117-136.

Appendices

Appendix 1

Questionnaire

- Your gender (M/F)

- Your age

- In Wal-Mart is the flow process deals related to logistics with respect to the products making and the establishment of the logistical flexibility required for serving the target markets? (Y/N)

- If yes, please explain?

- What kind of logistical flow is required to fulfill the needs and wants of the customers?

- Do you think incompatibility between the market characteristics and the manufacturing process can lead to business performance’s unfavorable impact in Wal-Mart? (Y/N)

- If yes, please elaborate

- What are other sub processes of Wal-Mart? Kindly explain your answer.

- What are the five performance objectives of Wal-Mart? Kindly explain your answer.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts