Designing Fluidized Bed Sand Biofilters

Introduction

The selection of a biofilter is said to essentially have an influence on the capital as well as the operating costs attached to the recirculating aquaculture systems, the consistency of the water treatment and the water quality. A good biofilter is thought to have the necessary capacity of removing the ammonia said to have entered the unit, support the microbial growth especially on an inexpensive materials, produce no nitrite, require no water maintenance or little pressure and only attract a small footprint (Ebeling, and Timmons, 2012).

Despite having all the significant factors, it is worrying that there is no specific type of the biofilter that would meet or address all the mentioned requirements (Lauderdale et al., 2012). Notably, a good range of the fluidized sand biofilters is known to have been adopted across North America. Most of the recirculating systems are also said to rely on the capacity of maintaining the excellent water quality for the purposes of producing such species that are not limited to the rainbow trout, the salmon smolt, the endangered fish, the arctic char and the ornamental fish. Based on this prerequisite, the discussion finds it necessary to develop one of the fluidized bed sand biofilter. This implies a significant focus on the related work, the design specification and the discussion at the same time.

Related Work

A range of studies are believed to have touched on the development process for the fluidized biofilters in different parts of the world where the technology is deemed necessary. One of such studies include the one developed by Lu et al. (2020), in which attention was focused on the Fluidized-bed Biofiltration Technology. Based on the authors, the design of the recirculating system is regarded significant in the sense that the process has to be cost-effective even in the light of the requirement that calls for the high water quality.

Across the Oligotrophic systems, the needful biofilters are expected to be of low cost for per cubic foot, as well as high surface area in a unit volume. The considerable fine sand media engaged in the biofilter facilitates the necessary surface area, which is around 7800 ft2/ft3, which is necessary property needed in making it act as the thin film reactor. According to the findings established by Bartelme et al. (2017), the mentioned property allows the biofilter to remove the entire ammonia available in a pass, and equally gives the system the room to be shock-loaded without compromising the water quality. It should equally be noted that around 200-1000 bacteria species are likely to flourish in the available sand media, thereby ensuring that the water is biologically stable.

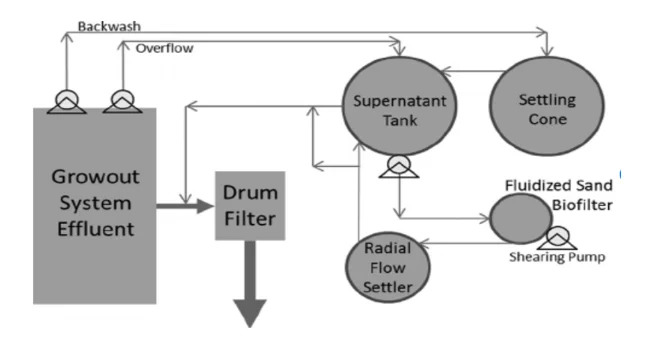

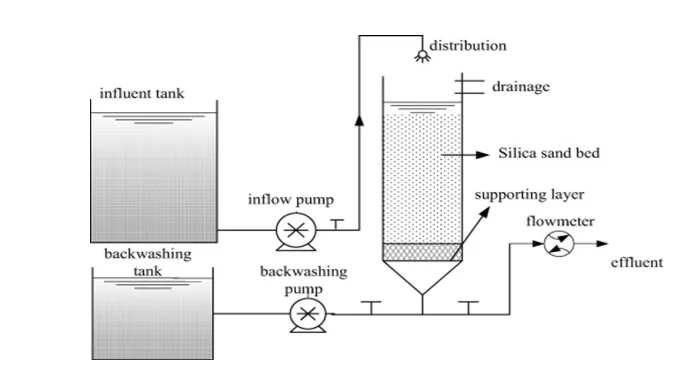

A series of the mechanical filters would still be needed in the removal of the suspended solids, as well as maximize the needful performance attached to the fluidized bed. In this context, a propeller-washed bead filter is highly recommended due to its efficiency when it comes to removal of the particles, as well as provides the needful low water discharge in the course of backwashing. Due the fact that the nitrification process may demand 2 ppm of the oxygen for each ppm of the removed ammonia, aeration needs to be included in the recirculating system design. The process of off-gassing the CO2 and the oxygen re-saturation is likely to be achieved in only a single pass characterized by a packed column. In addition, the disinfecting equipment as well as water sterilization can be attained with the help of the protein skimmer and the Ultra violet sterilizer. The two can be utilized in the recirculating system for the purposes of enhancing the water quality as well as its clarity. Ngo et al. (2017) further revisited the essence of flow injection and the necessary mechanism that would help the system to attain the same flow injection. The Fluid-Sand Biofilters, or the FSBs, require a uniform flow distribution, which is deemed significant or pertinent in the system operation.

On top of the distribution of the equal amount of the flow in the FSB, the flow distribution mechanism is highly needed for the purposes of meeting effective operations without encountering the detrimental fouling. Same attention is given to prevention of the loss of the filter sand, as well as support the needful sand bed across some of the significant designs. Based on the findings and observations made by Bello et al. (2017), five significant mechanisms have been established to essentially inject water into the FSBs found in the recirculating aquaculture systems. Notably, four of the systems have been linked to the pipe manifold, which runs from the top part of the FSB and the vertical side of the reactor to the significant base attached to the sand bed. The remaining mechanism is known as the CycloBio FSB, which is known for not using the pipe manifold while ensuring a supply to the cylindrical vessel. In the study of FSBs, Gichana et al. (2018) believed that developers have worked on a range of technologies meant for the removal of the nutrients which are not limited to phosphorus, cBOD5 and Total Ammonia-Nitrogen (TAN) from the aquaculture effluents. Such a move is believed to play a focal role when it comes to protection of the immediate environment. Among the technologies, Gichana et al. (2018) focused more on Biofiltration, which a technological approach applied in the treatment of the dissolved wastes is found in the recirculating aquaculture systems. Based on this approach, it is said that nitrification would occur across the biological filters especially when two significant and distinct groups of the autotrophic bacteria are engaged in catabolizing the unionized ammonia into nitrite. The same conversions happen during the mineralize nitrite, which can be converted to nitrate. It is worth noting that nitrite and the unionized ammonia re both toxic especially to the fish when the concentrations are low. This implies that the control or effective removal of the toxic substances is recommendable. Gichana et al. (2018) further noted the fact that Ammonia is the key item or the end product that is essentially produced at the end of the metabolism process of the protein catabolism. This waste is commonly excreted by fish in form of the unionized ammonia in the grills. It is also worth noting that nitrate, nitrite and ammonia are essentially soluble in the water. Under most circumstances, ammonia would prevail in two fundamental forms which include the ionized NH4+ and the un-ionized NH3. Therefore, the biological filtration forms the key item in the process of controlling the level of ammonia.

Design Specification

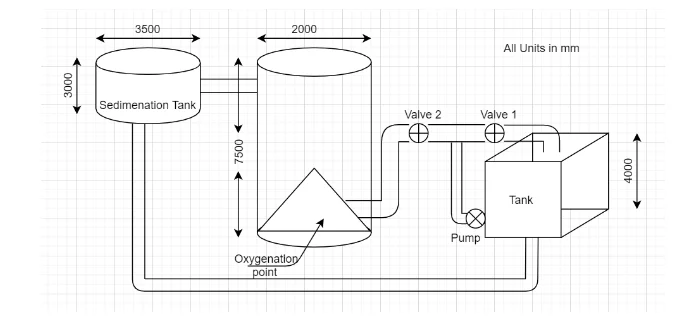

The implementation of the mentioned technology requires a proper design as well as management. Notably, the new system needs to be properly designed while taking into account the required water volume, the biomass, daily feed rates and the required water quality (Areerachakul, 2015; Liu et al., 2013). Some of the properties under consideration include the flow rate in the holding tanks, the water velocity, TAN production and water distribution in the system. While developing the design specification, nitrogen is apparently considered as the fundamental nutrient linked to all the living organisms. The design takes note of the fact that nitrogen is found in the pigments, pyridine nucleotides, adenosine phosphates and the nucleic acids among other components. Within the significant aquaculture environment, attention is given to the nitrogenous waste, which is rarely limited to amino acid, urea, organic debris as well as dying organisms among other forms of wastes (Barrett et al., 2011). In the real world encounter, the unit processes are usually linked together in the light of the fact that water would flow in almost each of the processes. Commonly, around 5-10% of the total discharge noted in the culture tank is commonly removed from the notable central drain. A study conducted by (Claësson et al., 2016) found that feeding rates for European eel (Anguilla Anguilla) are given as 1.33 kg feed/kg fish/day and 0.48% body weight day. However, in this design, the feed rate will be taken as 1.3 kg feed/kg fish/day at a body ratio of 60% for practical application. Based on the design specification, consideration of the following properties is deemed necessary.

Flow Rate through the Holding Tanks

Determining the flow rate requires assumption of a few things. If the system has to take 20 tonnes, then in a year, the system can have a production goal of 20 ton/yr

Fish loading tank is given by:

Loxygen =ΔO2 x 1,440O2 /consumption x FR

Where

Loxygen = fish loading limited by oxygen (kg fish/L/min)

ΔO2 = influent - effluent oxygen concentration (kg/L)

O2 consumption= oxygen consumption (kg/kg feed)

FR = feeding rate (kg feed/kg fish/day)

Determination of the flow rate in the holding tanks is expressed as

Qtanks = biomass/Loxygen

While determining the flow rate

The Biomass = Feed Conversion Ration (FCR) (Annual Production)/ rfeed

= 20000kg/year x 1.3kg feed/kg of fish being produced x 100 kg/1.2 kg x year/365 days

= 5936 kg

Oxygen requirements

RDO = Biomass x aDO x rfeed

= 20000 x 0.4/1 x 1.2/100kg fish in a day

= 96 kg/day

So Qtank = rdo x [1/(DOinlet – DOeffluent)]

Assuming that DOeffluent is 9 mg/L, DOinlet as 16 mg/L and DOsaturation as 10 mg/L, then it follows that

Qtank = 96 kg/day x 10^6/kg x day/1440 min x L/ (16 - 9)

= 9523 L/min

Total Ammonia-Nitrogen (TAN) production

The biofilter nitrification rates need to be based on the TAN conversion per unit especially when there is an unexpanded media volume. This would be referred to as the significant volumetric TAN conversion rate with standard units settling on the grams. Most of the TAN concentrations are commonly maintained below the 2 mg/L. However, most of the experiments have noted a linear relationship between TAN concentration and the TAN concentration rate. In this design

TAN production = (30 g x 0.01 x 1000)/ (60 x 100)

= 2.08 mg/L

Determination of the TAN produced in the recirculating aquaculture system takes into account a number of steps, which still applies to the system above. Some of the steps that need to be observed include identification of the maximum TAN concentration needed in the cultural tank, estimation of the maximum feed rate needed in the course of determining the total-ammonia nitrogen generation, and lastly, the experience of the manufacturers on the specifications of the VTR as well as the biofilter media. When there is freshwater RAS working at the temperature of 25oC, then it follows that the concentration of dissolved oxygen is expected to go above 4 mg/L. When the system has an alkalinity of 100 mg/L and a pH of 7.2, then the desirable TAN concentration should settle at a maximum of 2 mg/L. Based on the conditions and taking feed amount as 60kg, TAN produced would be expressed as

TAN produced = 60 kg Feed in a day x 0.16g Nitrogen x 50% Nitrogen x 40% protein x 1.2g TAN/g

Therefore

TAN produced = 2.3kg TAN/day

This kind of TAN produced would attract a Biofilter media volume, which is essentially expressed as

TAN production/VTR

= 2300 g/ 90 g TAN removed = 4.27

= 25 m3

This means that the trickling filter would be around 25 m2, while the media height settles at 4.0 m. While focusing on the trickling filter, more attention is given to the biofilter media and the space above. Therefore, the needed volume of the bed media would be estimated by

TAN produced/Tan Removed

Taking the parameters into account, as stated above, the volume needed for the bed media is expressed as

2300/350

= 6.57 m3

Water Velocity

The water velocity encountered in the course of the test condition can essentially be determined through the water flow rates said to have been recorded. This means that the flow rate can be divided by the cross-sectional area attached to the column.

V = Qbiof/Ab

The flow rate in question was determined earlier in the previous calculations. The Qbiof settles at 0.56 L/min. Therefore, when the area is 0.29cm2, the velocity at 150% expansion would be determined as

V = Qbiof/Ab

= 0.56/0.29

= 1.93 cm/s

At this rate, the 20% expansion would attract a velocity of around 0.5/0.4 when the uniformity coefficient is around 1.8, the mesh sizes are 40/70 and the effective size for the D10. When the sieve mesh size is around 30/50, the effective size would be 0.45, the uniformity coefficient would stand at 1.4, and these parameters the velocity requirements for the 50% expansion of 1.3/1.5.

Cross-sectional Area of the Biofilter

Bed depth can be chosen at random

Bed depth = 0.75 m

This means that the

Area = volume/depth

= 0.48m2

TAN Removal Rate

The TAN removal efficiency is one of the most significant parameters in the design of the Biofilters. Given the media and the specific area attached to the substrate, the TAN removal rate would be expressed in terms of kg TAN/m2/day. The TAN out would be determined as

TANout = {1/ (1 – R + (Rfrem) x {RTAN /QBiof x 106(mg)/1(kg) x 1(day)/1440(min)}

TANout = {1/frem} {RTAN/Qbiof x 1(day)/1440(min) x 106/1}

Given the design flow is 83 gpm, and the packing density as 226m2/m3

The TAN removal rate would be

= 1.5 ppm

The volume of media

It should be noted that nitrogen and phosphorus can biologically be removed. The nitrification as well as denitrification processes are deemed significant in the determination of the volume of the media needed. If the

Crop size is 60 kg

The allowable TAN is 1.5 ppm

Ammonia produced is 130 gm /day

Surface are needed is 200 m2

The Hydraulic loading is 5.2 gpm /ft2

This means that the appropriate volume of media is approximately

Volume of media = 2.21 m3

This can be expressed as,

Volume of media = 78 ft3

Discussion

FSBs are essentially applied in the recirculating aquaculture systems, which are utilized in the absolute removal of the ammonia nitrogen said to be produced on a daily basis. A better mass balance would be needed in accounting for the TAN production. The exchange rates are needed in the biofilter for the purposes of retaining a convenient TAN concentration. The mass balance would consistently manifest the idea of treating the biofilter anywhere within the range of 50-100%. It is worth noting that the recirculating water does not necessarily need to be treated in the biofilter. This is due to the fact that the system has a way of making sure that the dissolved carbon dioxide is increasingly removed, or there is an increase in the transportation of the additional dissolved oxygen (Neagu et al. 2017). The significant size of the biofilter is essentially determined by the bed depth and the cross-sectional area, as well as the size of the needful sand that is picked for the potential treatment capacity. Upon identification of the biofilter flow rate, there is need to assume the sand and the needful cross-sectional area requirements. The design parameters can still be adjusted or modified in terms of the sand and tank diameter before reaching the most convenient size. Such adjustments pave way for the graded sand; boost the potential of the treatment capacity. Notably, the static sand that is introduced into FSB, which is designed to take a depth of 1-2.5, remains pertinent with correspondence to the bed oxygen demand, total head loss limits, the vessel geometry restrictions and the vessel height limitations. For a good working biofilter, the bed depth is supposed to fall within the range of 2m to 5m. However, these parameters can largely be determined by kind of the situation at hand. A line of factors considered to be necessary include the TAN mass that needs to be removed in a day and the TAN removal efficiency. It is worth noting that the TAN mass being removed would be increased based on the hydraulic loading rate, which is subsequently determined across the biofilter. It should also be noted that a rise in the hydraulic loading rate in the FSBs would equally decrease the available TAN removal efficiency. Such a case would be accompanied with shortened water retention, as well as the TAN mass load. The TAN concentration said to be discharged from the culture tank is fundamentally regulated by the notable frem in the biofilter. Significantly, average daily rates of the TAN being produced would also be determined by a fraction of the water flow which is being reused, and the rate of the water being recirculated across the biofilter. A further integration of the CycloBio in the system is said to have the slotted inlet manifold said to have been first designed by the Marine Biotech Inc. This enhances the application of the design across the recirculating aquaculture systems (Cárdenas-Calvachi and Sánchez-Ortiz 2020). Essentially, the flow distribution mechanism is utilized in framing the false-floor distribution mechanism, the vertical pipe manifold and the horizontal pipe-manifold. The FSB would tangentially inject water into the fundamental annular space known to surround the entire base of the significant circular vessel. This would still be integrated with the necessary vessel wall while developing the strong water rotation. An inverted cone would be introduced at the appropriate center of the vessel, which is something that would enhance the upward-flowing water velocity thereby improving the sand bed expansion. The CycloBio is pertinent in the determination of the slotted inlet design, which is deemed convenient in terms of introducing the air in the agricultural livestock buildings. The subsequent rotating flow is necessary in terms of imparting the cyclonic rotation especially across the expanded sand bed and the sand bed expansion (Neagu et al. 2017). At the same time, the FSB would have to function at a head-loss attached to the flow inlet slot, which stands at 1.5-2.0 psig or the 0.2-0.4 psig less than the recommendable head-loss said to be designed and integrated into the horizontal pipe manifold. It is worth noting that the cyclonic rotation linked to the sand bed largely contributes towards the uniform bed expansion in the FSB. This means that the FSB would essentially appear to work more uniformly while fostering the expansion of the bed depth that would go at twice the necessary diameter of the appropriate vessel implemented in the context. Under the conditions, the CycloBio is found to be simple in terms of the operations as noted with the blind flange, the annular chamber and the pump utilized in making a supply to the flush. With the design under consideration, the FSB can easily be re-fluidized and still clear the sand that is remaining in the annular chamber without necessarily removing the water in the vessel.

Conclusion

The report has focused on the design and the development of the fluidized-bed sand biofilter. The design process has taken into account the related work, which touches on the technologies said to be used in other systems believed to have been noticed in such regions like North America. The design process further tapped into the same technology while developing the system under consideration. The design specification has taken into account significant parameters that are not limited to the volume of the media, the water flow in the system, the discharge rates, the cross-sectional area of the vessel and the TAN production.

References

Areerachakul, N.A.T.H.A.P.O.R.N., 2018, January. Biofilters in recirculation aquaculture system. In 96th The IRES International Conference, Amsterdam, Netherlands (pp. 16-19).

Bartelme, R.P., McLellan, S.L. and Newton, R.J., 2017. Freshwater recirculating aquaculture system operations drive biofilter bacterial community shifts around a stable nitrifying consortium of ammonia-oxidizing archaea and comammox Nitrospira. Frontiers in microbiology, 8, p.101.

Bello, M.M., Raman, A.A.A. and Purushothaman, M., 2017. Applications of fluidized bed reactors in wastewater treatment–A review of the major design and operational parameters. Journal of Cleaner Production, 141, pp.1492-1514.

Cai, Y.A., Li, D., Liang, Y., Luo, Y., Zeng, H. and Zhang, J., 2015. Effective start-up biofiltration method for Fe, Mn, and ammonia removal and bacterial community analysis. Bioresource technology, 176, pp.149-155.

Gichana, Z.M., Liti, D., Waidbacher, H., Zollitsch, W., Drexler, S. and Waikibia, J., 2018. Waste management in recirculating aquaculture system through bacteria dissimilation and plant assimilation. Aquaculture International, 26(6), pp.1541-1572.

Hermawan, A.A., Talei, A., Leong, J.Y.C., Jayatharan, M., Goh, H.W. and Alaghmand, S., 2019. Performance assessment of a laboratory scale prototype biofiltration system in tropical region. Sustainability, 11(7), p.1947.

Lauderdale, C., Chadik, P., Kirisits, M.J. and Brown, J., 2012. Engineered biofiltration: Enhanced biofilter performance through nutrient and peroxide addition. Journal‐American Water Works Association, 104(5), pp.E298-E309.

Lu, L., Dong, D., Baig, Z.T., Yeung, M. and Xi, J., 2020. Development of a novel fungal fluidized-bed reactor for gaseous ethanol removal. Chemosphere, 244, p.125529.

Tsukuda, S., Christianson, L., Kolb, A., Saito, K. and Summerfelt, S., 2015. Heterotrophic denitrification of aquaculture effluent using fluidized sand biofilters. Aquacultural Engineering, 64, pp.49-59.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts