Ultra-High-Performance Concrete in Global Construction

INTRODUCTION

ULTRA HIGH-PERFORMANCE CONCRETE:

In the recent era of globalisation, there is digital transformation along with concrete technology and in this context ultra-high-performance concrete (UHPC) is an outstanding additional development. It has a compressive strength of more than 150 MPa with longer service life as compared to the high performance concrete. The major properties of such UHPC are durable, sustainable, and economical applications in various types of structures and it is playing an important and unavoidable role in building the strong infrastructure. Durable, sustainable, and economical applications in various types of structures is utilised across several countries including Japan, North America, Korea, and Australia. It would be worth to utilise UHPC where it further influence the people for identifying the composition, development, longevity, and general properties of UHPC. UHPC is considerably more expensive than conventional concrete, however UHPC is utilised widely as it is very durable and it further offers excellent protection for embedded steel reinforcement. In such context, Ultra High Strength Concrete (UHPC) is mainly defined the concrete with compressive strengthen which is greater than 150 MPa [1, 2, 3].

for making UHPC, it is required to have high-strength steel fibres, fine sand, cement, fly ash, a large volume of SF, and a small amount of water (a / cm ratio of less than 0.20). Graybeal (2006) stated that, chloride permeability is measured according to ASTM C 120212 and it is less than 100 coulombs, a very low permeability. Chloride penetration in a 5 µm wide crack of only 5 mm has been shown in the bending cracks in the structural beams. The small cracks are associated even with highly stressed UHPC and this resistance of chloride penetration and carbonization is generally high. The definition of the AFGC (French Association of Civil Engineering) establishes that UHPC is a concrete with a compressive strength in the range of 150 and 250 MPa. Through this, it is possible to improve cementations material with sufficient strength, sufficient ductility, and high durability. For achieving ductile behaviour under tension, it is possible to utilise steel fibres which are being split by its active or passive conventional reinforcement. There are four phases of development of ultra-resistant concrete which are H. before 1980, duration 1980, duration 1990 and after 2000 [1, 2, 3].

LITERARURE REVIEW:

MIXTURE OF NATURAL AND STEEL FIBRE IN UHPC

There are promising alternatives to synthetic fibres in concrete which are natural fibres including jute, sisal, flax, coconut, and hemp and with an increasing attention to the sustainability of building materials, the use of such materials is rising across the countries [4], [5], [6], [7]. Natural fibres have shown high potential to prevent UHPC from flaking at high temperatures and it has also been found that, the interfacial spaces can be created for the contraction of the natural fibres that is conducted between the comment matrix and fibres, this further leads to increase in the permeability of UHPC at high temperature. Studies on the combined use of steel and natural fibres are quite limited for which the information ion the hybrid fibre content is necessary to prevent flaking and explore the mechanism to mitigate flaking further [10]. There are many studies on the steel fibres that can increase the compressive strengthen of concrete. The current work is useful for increasing understanding about the synergistic effects of natural fibres and steel fibres that affects the chipping resistance and mechanical properties of UHPC [11, 12, 13]. A scanning electron microscope (SEM) and thermal analysis are effective for examining the changes sin the microstructure and analysing its impacts of fire on the extent of spilling. For further evaluation of the performance of the hybrid fibres, it is also possible to consider the measurement of chipping resistance, mass loss, compressive strength and permeability.

APPLICATIONS OF ULTRA HIGH PERFORMANCE CONCRETE USING HYBRID FIBRES:

Different materials and sizes to the mix must be considered in order to analyse the different types of fibres as it improves the effectiveness of preventing the information and rogation of cracks in the tensile zone. Smaller fibres prevent micro cracks, when the larger fibres cracks further prevent the cracks to spread if there is wider opening [16].

SPALLING BEHAVIOUR OF HYBRID FIBERS IN UHPC:

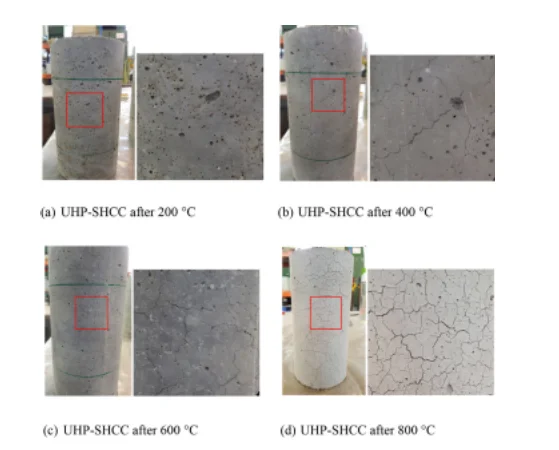

The example of flax fibre is considered here as a natural fibre and proceeding with the spilling behaviour of the sample. Table 2 below summarises the chip test result of UHPC samples by considering different flax fibre contents and steel. Three control samples completely separated from ST0F0 is considered which results to leaving very small fragments of less than 1 cm in length. Traversing the photos vertically from the upper left corner adds the steel fibre that did not prevent the UHPC from peeling regardless of the steel fibre content. Additionally, the samples were also severely detached even with 3% by volume (236 kg / m3) of steel fibres. After the chip testing, small fractions of sample remains there and further the addition of flax fibre alone did not suppress peeling [14]. The ST0F6 samples even with 6 kg / m3 flax fibres (but not steel fibres) broke into various segments with cracks throughout the section, when looking at the photos horizontally and the chipping behaviour has also been explored through UHPC with insufficient PP fibres. the performance of other natural fibres prevent the faking activities as 6 kg / m3 of flax fibres were not enough to prevent flaking of UHPC. Hence, it can be stated that, there is a very high dose of jute fibres (~ 10 kg / m3) that was necessary to prevent the UHPC from shedding [10]. There is a synergistic effect in preventing flaking with the combined use of steel and flax fibres. The addition of steel fibres alone cannot prevent flaking where some does of flax fibre that was able to improve the resistance to flaking. Adding 2 kg / m3 of flax fibres, ST1F2 could remain intact with more pieces than ST0F2 explained through the table 2 below. Additionally, flaking is being avoided in ST1F6, with a combination of 1% by volume steel fibres and 6 kg / m3 flax fibres. It has been found that, the flax fibre content required for preventing the flaking was reduced with the increasing steel fibre content. The ST2F4 and ST3F2 samples are effective for good chipping resistant and with constant fibre content of 1 and 2% by volume it is possible to raise the flax fibre content with the chipping resistance of UHPC. ST3F6 is corresponding to less flaking in two of the three samples with a constant steel fibre content of 3% by volume. Furthermore, ST3F2 and ST3F4 exhibited less flaking with the small pieces of concrete peeling off the samples. In ST3F6, the total numbers of fibre is large and further affects the concrete, workability and uniform distribution of fibre. Hence, the chipping resistance of ST3F6 was decreased compared to ST3F4 or ST2F6.

The mass loss rate of UHPC samples before and after the chipping tests are represented through the figure 4. It has been explored that, the degree of spalling in the current study could be divided into five groups with the rate of mass loss. The ST0F0 control samples showed 100% mass loss as the entire sample in the set exploded into very small debris. Mass loss rates higher than 80% can be shown under the samples with severe flaking, d. H. ST0F2, ST1F0, ST2F0 and ST3F0. It further indicates moderate scaling. The mass loss rate was only between 10% and 30%, for ST2F2, ST1F4, and ST3F6. It indicates that, only the samples were able to remain largely intact and the sample flaking occurred. For the mass loss rates were around 10% with the samples without scale, it is mainly caused by the loss of the moisture and the breakdown of the hydration products [10].

RESIDUAL MECHANICAL PROPERTIES:

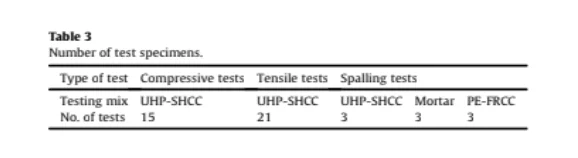

Figure 3 is effective for determining the remaining properties of UHPSHCC, cylindrical specimens (f100 to 200 mm) and dog bone specimens as well as uniaxial compression and tensile tests, respectively. For both the compression and tensile test, it is also required to consider a path controlled load regime and for this the configurations for the compression and tensile test are developed through Figures 4 (a) and (b), respectively. In this case, the displacement load speed was 0.2 mm / min. The internal compression force is also measured with a load cell and the axial displacement was also recorded with an LVDT assembly for capturing the complete compression stress-strain curve. Additionally, LVDTs are a sensor which is also utilised to determine the linear displacement of the specimen and three LVDTs were placed in the midsection of the cylindrical specimen, forming an angle of 120 between successive LVDTs. this further helps to have more accurate measurements of average compressive stress. The measurement length of the three LVDTs was 100 mm. For maximum load level, the readings for these three LVDTs are valid. The cracks in the sample continued to widen is the maximum loads was reached. Three LVDT readings of the quite erratic along with two additional LVDTs are utilised to measure the sample strains between the machine and plates. Strains mainly include compression elongation of the sample, end zone effect, and plate movements of the machine. Mansur et al. [1]. For developing the stress strain curves for UHPSHCC (ultra-high-performance strain hardening cementations composites), it is required to record the tensile force with a load cell and the displacement that were also measured with two external LVDTs attached to the 100 mm long dog bone sample with a measuring device. As in FIG. 4 (b), the cylindrical specimens were exposed to the following isothermal temperatures: 30 ° C (room temperature), 200 ° C, 400 ° C, 600 ° C, and 800 ° C for compression tests. For tensile tests, Dog bone samples are required for following temperature 30 ° C (room temperature), 100 ° C, 200 ° C, 300 ° C, 400 ° C, 500 ° C and 600 ° C Tests is less than those of pressure tests. The tensile properties of the UHPSHCC are more sensitive to changes in temperature. The pressure and tension samples were dried to the constant mass at 105 ° C before heating in case of the target temperature was above 105 ° C.

Residual compressive test:

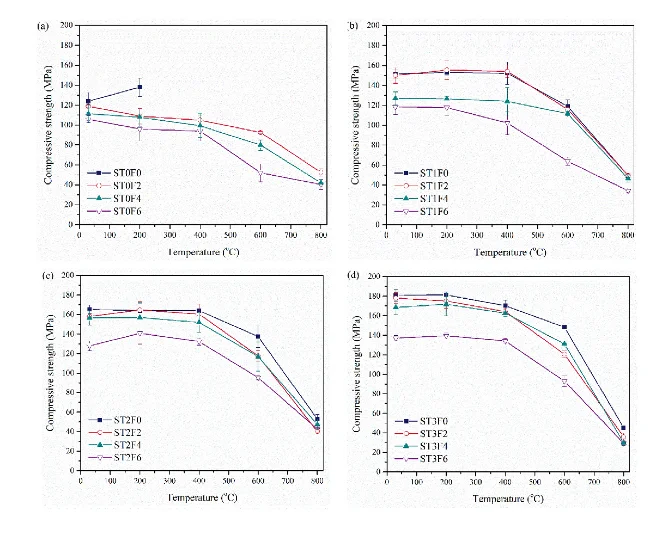

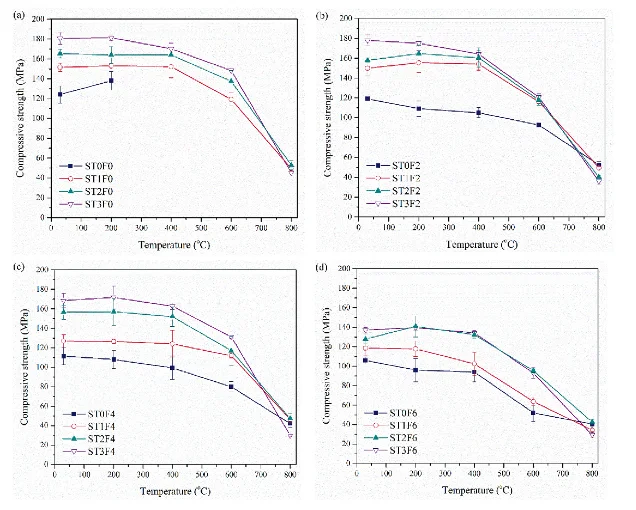

Figure 13 represents Compressive strength of UHPC with hybrid fibres where increasing steel fiber content enhances compressive strength while adding flax fibers has a reverse effect. Generally, 2 kg/ m3 of flax fibres cause negotiable reduction in the compressive strength of UHPC. A reduction of about 15% could be found in samples with a flax fibre content of 6 kg/m3 [10]. Reduction in compression strength caused by flax fiber occurs in the samples regardless of the steel fiber content. Illustrating the effects of steel and flax fibers can be developed through e.g. ST3F2 and ST2F4 samples (Table 2). The steel and flax fibers could result in spalling-free UHPC for illustrating the high compression strength at high temperature. As show in Figs. 14 and 15, the compressive strength only reduced slightly below 400 ◦C. furthermore, the deterioration of the compression strength at 400 ◦C might be caused by the decomposition of hemi-cellulose and α-cellulose in flax fibers [18-20]. Increasing steel fiber content leads to compression strength of UHPC increased. Increasing steel fiber content decreased the space between fibers, allowing more steel fibers to bridge micro cracks and sustain loads [17].

A huge mass loss of ~60% can be observed between 300 and 400 ◦C that could cause of the reduction in the compression strength and it is explained through the TGA data in Fig. 8. In UHPC with only flax fibers (Fig. 14a), higher flax fiber content lead to a sharper decreasing rate. Compression strength is associated with decreasing significantly at temperatures above 600 ◦C. The compressive strength of ST0F6 was 52.1 MPa at 600 ◦C, which was a drop of ~50% from the value at ambient temperature. Additionally, compressive strength of ST0F2 was 92.6 MPa is associated with the reduction of ~22% compared to the strength at ambient temperature. Adding steel fibres generally increased the residual compressive strength of UHPC at 600 ◦C (Fig. 15). These are also known as dehydration, shrinkage, decomposition of calcium hydroxide, and phase change of aggregate occurs at high temperatures and causes the deterioration of UHPC [21-23]. With the increase of the residual compressive strength of UHPC increased, there is increasing steel fiber content.

Take a deeper dive into The Advent of Mobile Phone Technology with our additional resources.

The degradation of fibers and reduction of steel-fiber-matrix bonding can be represented in Figure 7. The steel-fiber-matrix bonding decreased significantly at 600 ◦C, steel fiber could still enhance compressive strength and on the other hand, high steel fiber content led to great residual compressive strength after exposure to 600 ◦C. After exposure to 800 ◦C, the compressive strength of all the mixtures decreased to below 55 MPa [24-25]. Generally, a combination of steel and flax fibers showed a good performance in compressive strength at high temperature [26-27]. It is hereby important to study the long term durability of the whole system and identify the effects of long term changes on the spalling resistance. Development of a spalling-free UHPC can also be possible through such analysis by maintaining its temperature.

The influence of excessive water content in the mechanical properties of UHPSHCC can be eliminated for preventing the formation of explosive flakes. The samples heated to target the temperature at 1 C / min. low heating rate is also utilised by the users in order to avoid explosive spalling during the heating phase. The samples were immersed in this environment for 1 hour to achieve an isothermal state before the naturally cooled in the oven in case of reached target temperature. All samples were analysed after 28 days [2]. The samples were heated in the oven to 400- C in 7 minutes as well as the temperature was kept constant for 2 hours. A perforated steel cage was utilised in this case in order to cover the samples for preventing flaky debris from damaging the internal heating elements while thermal convection occurs. A high heating rate of 53, C / min was utilised for investigating sensitivity to flaking, as it approaches real fire scenarios and is more likely to trigger explosive flaking [3].

Conclusion:

The combined effects of steel and flax fibers on spalling resistance and compressive strength is being investigated efficiently through this study and the findings are such as, (1) Adding steel fibers or flax fibers alone is not possible to prevent spalling of UHPC in the current study, even with the high fiber Adding steel fibers or flax fibers alone could not fully prevent spalling of UHPC in the current study. To high contents of both the fibers could negatively affect the spalling resistance due to workability issues of fresh concrete. The combined use of steel and flax fibers showed improved resistance of UHPC and also prevents spalling with low fiber content. (2) At ambient temperature, steel fiber mainly increased compressive strength and the flax fiber reduced compressive strength. A combination of steel and flax can stop reduction in compression strength as flax fiber results high compressive strength. (3) The compressive strength of UHPC reduced after exposure to 400 ◦C. steel fibres could enhance residual compressive strength in case of temperatures below 600 ◦C. the higher the steel fiber content, the greater the residual compressive strength as well as flax fibers reduced the residual compressive strength after exposure to high temperatures. At exposure to 800 ◦C, the compressive strength of the mixture reduced to below 55 MPa. (4) The synergistic effects of steel and flax fibers in spalling prevention further enhances permeability and a bridging effect on the propagation of microcracks. Increase in permeability is caused by the mechanisms of flax fibres shrank at high temperature, creating interfacial gaps between them and the surrounding cement matrix. Steel fibres created microcracks with high temperature expansion and meeting of microcracks (formed by expansion of steel fibres) with interfacial gaps (due to shrinking of flax fibres) enhanced connectivity.

REFERENCES:

[1] M. Mansur, T. Wee, M. Chin, Derivation of the complete stressestrain curves

[2] V. Kodur, Spalling in high strength concrete exposed to fire: concerns, causes,

[3] K.D. Hertz, Limits of spalling of fire-exposed concrete, Fire Safety J. 38 (2)

[4] F.d.A. Silva, B. Mobasher, C. Soranakom, R.D.T. Filho

[5] O. Onuaguluchi, N. Banthia Plant-based natural fibre reinforced cement composites: a review Cement Concr. Compos., 68 (Supplement C) (2016), pp. 96-108

Bio-Inspired, Internally Cured Cellulose Fiber Reinforced Concrete for Next Generation Infrastructure, vol. 326, ACI Symposium Publication (2018)

A review of Australian research into natural fibre cement composites

Effects of various fibres on high-temperature spalling in high-performance concrete. Construct. Build. Mater., 71 (2014), pp. 83-92

Preventive effects of polypropylene and jute fibers on spalling of UHPC at high temperatures in combination with waste porous ceramic fine aggregate as an internal curing material

Achieving slip-hardening behavior of sanded straight steel fibers in ultra-high-performance concrete

Development of ultra-high performance fibre reinforced concrete (UHPFRC): towards an efficient utilization of binders and fibres

Synergistic effects of hybrid polypropylene and steel fibers on explosive spalling prevention of ultra-high performance concrete at elevated temperature

D. Ray, B. Sarkar, R. Basak, A. Rana, Study of the thermal behavior of alkali-treated jute fibers, J. Appl. Polym. Sci. 85 (12) (2002) 2594–2599

D. Zheng, R.-Y. Ding, Z. Lei, Z. Xingqun, Y. Chong-Wen, Thermal properties of flax fiber scoured by different methods, Therm. Sci. 19 (3) (2015) 939–945

G.-F. Peng, W.-W. Yang, J. Zhao, Y.-F. Liu, S.-H. Bian, L.-H. Zhao, Explosive spalling and residual mechanical properties of fiber-toughened high-performance concrete subjected to high temperatures, Cement Concr. Res. 36 (4) (2006) 723–727

C.S. Poon, Z.H. Shui, L. Lam, Compressive behavior of fiber reinforced high-performance concrete subjected to elevated temperatures, Cement Concr. Res. 34 (12) (2004) 2215–2222

W. Zheng, H. Li, Y. Wang, Compressive stress–strain relationship of steel fiber-reinforced reactive powder concrete after exposure to elevated temperatures, Construct. Build. Mater. 35 (2012) 931–940

Y. Li, E.-H. Yang, K.H. Tan, Effects of heating followed by water quenching on strength and microstructure of ultra-high performance concrete, Construct. Build. Mater. 207 (2019) 403–411.

J. Wei, Degradation behavior and kinetics of sisal fiber in pore solutions of sustainable cementitious composite containing metakaolin, Polym. Degrad. Stabil. 150 (2018) 1–12.

J. Wei, C. Meyer, Degradation rate of natural fiber in cement composites exposed to various accelerated aging environment conditions, Corrosion Sci. 88 (2014) 118–132.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts