Vibration Monitoring for Power Plant Efficiency

Introduction

The efficient operation and long-term use of equipment's in power plants requires techniques for diagnosis for purposes of improving reliability and further cutting the costs of operation and maintenance. Proactive, condition-based and predictive maintenance are of concern in the upcoming core technology for predictive breakdown maintenance. To apply them, it is quite critical to come up with a system for monitoring vibrations (Yang et al., 2014). This paper is a description of the development of a diagnosis system for vibration condition monitoring created for rotor and stator winding integrity assessment of class gas turbine generator of 100MW in a combined-cycle thermal plant. The life of a generator is degraded by the secondary impacts of accidents, damage of generators, breakdown, and stops of power plants that come unannounced. These factors also affect the stability of power systems, highlighting the importance of reliable solutions and, when necessary, resources like engineering dissertation help to ensure thorough analysis and effective implementation.

The stators windings vibrations especially abrade the insulation that exists on the blocking and bracing points of insulation. Both mechanical and magnetic forces induce the stator slots vibrations. A vibration condition monitoring system will be necessary as it will help in the improvement of savings costs of operation and maintenance costs regarding the power plant`s reliability. The instability of the power system coupled with the high levels of vibration lead to the damaging of a generator. Notably, whenever there is a fault in the generators stator winding, huge costs are generally incurred in the maintenance, and it would require up to 15 days to be repaired. It is always necessary to develop a condition monitoring system making use of the shorted-turn signals for purposes of improving the operation and using PD signals together with vibration signals (BS ISO 13381-1:2015).

In the upcoming core technology for predictive breakdown diagnosis, proactive, condition-based and predictive styles of maintenance are all maintenance forms that are of interest. Management of a facility with pieces of equipment that are continuously improved is entirely necessary. This leads to the improved operating efficiency of the material. Rotor vibration in most instances is usually a result of thermal bending which is also brought about by different kinds of thermal bending`s systems for monitoring and diagnosis of the condition of the rotors of a generator usually are significant factors for reliability of operations, in terms of creating preventive diagnosis and minimizing the chances of breakdown which could be secondary. Development of an integrated system for monitoring and diagnosis which has the capabilities of preventing outages that are catastrophic is quite important.

Developing an integrated system for condition monitoring

Hardware configuration

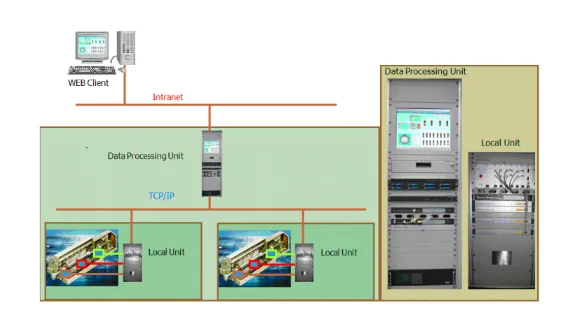

In the figure above, the configuration of the system for condition monitoring is shown. The proposed method is to be combined with the partial discharge signals, vibration signal, the shorted turn signal and the rotor vibration signal for purposes of monitoring the electrical and mechanical states of the generator.

The local unit will be made up of an Analogue / Digital board, an analog board. To facilitate condition monitoring that is real time, the DSP board will be developed into a dedicated board. The integrated condition monitoring systems Data Processing Unit receives the signals output that is usually delivered from the local unit.

For stator windings, optimal conditional monitoring, the tangential directions and radial directions of both stator and PD sensors will be installed with optical vibration sensors. Additionally, a sensor will be developed which will be capable of measuring the generator’s flux of shorted-turn winding rotor and its installation will be at the core side. Optical fibre accelerometers of the Bragg-grating type will be used for stator winding. They are often suitable for the high currents and voltages strong magnetic currents.

Whenever vibrations happen, the change of the wavelength of the light will be detected by the sensors. Vibration analysis consists typically of listening to the inside of a machine. The different components of a machine are observed to have different patterns for vibration and as such characteristic noises are generated by various devices which leave typical fingerprints in the spectrum taking the form of a linear trend. In instances where damage is present, the pattern is observed to stand out from the noise on the floor. This puts specialists typically in a position of recognizing, for example, whether the problem is as a result of an imbalance, bearing damage or misalignment. In addition to a diagnosis that is accurate, generally, it is also possible to establish if urgent action is essential or whether it could be pushed forward to the next scheduled servicing.

Vibration analysis is as such, beneficial to both maintenance technicians and operators. Some of the benefits of vibration analysis are that; 1) it facilitates the identification of faults in machines and further provides information on root causes, 2)localizes those components that have been affected, 3) optimizes logistics for spare parts 4) and also allows for the early planning of measures for maintenance (Zarei,Tajeddini, and Karimi, 2014).

The software of integrated condition monitoring and system for diagnosis

The .NET Framework 3.5 will be used to develop the configuration for the design of the software for the integrated Human Machine Interface. Microsoft develops the .NET Framework 3.5. UDP communications will be used for linking and embedding the Rotor vibration`s HMI, shorted-turns HMI (User Datagram Protocol) and stator vibration`s HMI. While file DB will be utilised for predictive analysis of transient condition, SQL DB will be used for the day to day operations. The left side of the monitor in the integrated condition monitoring and diagnosis systems screen view will show the electrical condition part while the right-hand side is the mechanical monitoring part. The control of the general rotor vibration part will be displayed in the right upper portion, while the bottom will be stator windings part for monitoring vibrations. The stator windings PD monitoring local part will be found on the upper left part, while the rooter shorted-run screen for monitoring is found on the lower part. The vibration characteristics ordinarily prevalent in the generator usually are utilised in learning the pattern of the prediction of mechanical wellbeing via the application of the algorithm of the error back-propagation. In instances when a diagnosis of a stator winding`s health will be made, monitoring of the waves of vibration from the tangential and radial sensors which are optical, and will be done so as to represent the behaviour of the stator. Consequently, learning patterns will be developed via the extraction of each phase’s variations on 120Hz reactions as a result of forces that are electromagnetic and 60Hz responses of rotor rotation. Chances of a resonance occurrence can easily be assessed through learning the outcomes of the operating generators patterns by error-back propagation (BS ISO 13372:2012).

Site Acceptance Test

Stator vibration analysis of signals, vibration analysis of rotor signal, shorted-turn signal analysis and will be included in the program for the integrated system for condition diagnosis and monitoring. To determine the conditions of the networks` for monitoring and assessing, a site acceptance test will be done on a 100MW class gas turbine-generator. This test will include in it the in-place functional testing of the parts of the hardware system, for example, the local unit, web-based modules and the DPU, optical sensors, shorted-turn sensors, and PD sensors. The integrated systems for condition monitoring that are being developed for example optical sensor data display, stator predictive failure diagnosis displays, stator vibration trends, and spectrums, trades of the PD`s signal and plots shorted-turn wave pattern displays, data management capabilities and web-based displays of the SQL database will be tested thoroughly. The condition monitoring systems reliability is confirmed by a comparison of the measurements results with the appropriate equipment (Ambhore et al., 2015).

Conclusion

Advanced technologies for systems of condition monitoring that are online in large rotating equipment for equipment like generators used in power plants are generally avoided because of the monopoly and the high value-added nature of the systems (BS ISO 13373-7:2017). This integrated system for condition will be developed for the power plants winding systems reliable operation reliable operation. To determine the working performance of the integrated monitoring and assessment systems, a site test of acceptance will be done at a class gas turbine generator of 100MW in a combined-cycle thermal power plant that will be chosen as the key plant. The output data of the integrated condition monitoring systems, will be compared with the analysis results obtained from local inputs local signals through the use of equipment that are precise to confirm the reliability. The integrated system will include in it a PD diagnostic subsystem, a vibration condition monitoring and diagnostic system, a shorted turn diagnostic system and a diagnosis system for stator and rotor. Additionally, an option for learning-patterns management will be added for purposes of diagnosing imminent failure for stator winding by making use of the optical sensor signals of each side.

References

- Ambhore, N., Kamble, D., Chinchanikar, S. and Wayal, V., 2015. Tool condition monitoring system: A review. Materials Today: Proceedings, 2(4-5), pp.3419-3428.

- BS ISO 13372:2012 Condition monitoring and diagnostics of machines – Vocabulary.

- BS ISO 13373-7:2017 Condition monitoring and diagnostics of machines – Vibration condition

- BS ISO 13381-1:2015 Condition monitoring and diagnostics of machines – Prognostics. Part 1: General guidelines. Monitoring. Part 7 Diagnostic techniques for machine sets in hydraulic power generating and pump-storage plants.

- Whan Kim, Y., Young Ho, J. and Shin Lee, Y. (2012). Development of vibration condition monitoring system applying optical sensors for generator winding integrity of power utilities. International Journal of Modern Physics: Conference Series, 6.

- Yang, W., Tavner, P.J., Crabtree, C.J., Feng, Y. and Qiu, Y., 2014. Wind turbine condition monitoring: technical and commercial challenges. Wind Energy, 17(5), pp.673-693.

- Zarei, J., Tajeddini, M.A. and Karimi, H.R., 2014. Vibration analysis for bearing fault detection and classification using an intelligent filter. Mechatronics, 24(2), pp.151-157.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts