Enhancing Material Properties with Laser Surface Treatments: A Comprehensive Overview

Chapter 1: Introduction

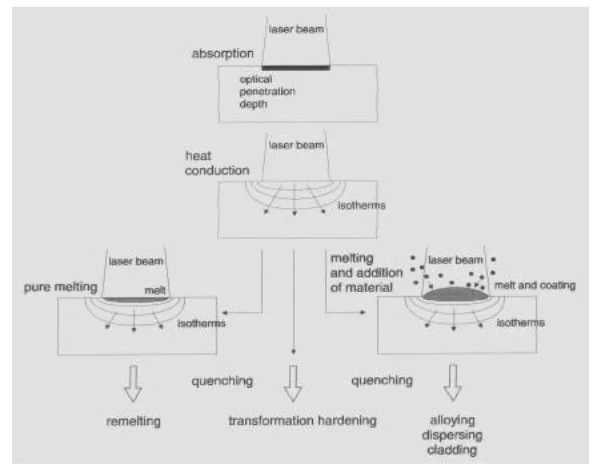

Laser surface treatments comprise of a group of procedures, for example, transformational hardening, softening, alloying and cladding (Adel, et al., 2009). It permits one to construct a section with totally unique properties in the surface layer from the mass material (Brown & Arnold, 2010). As such, the surface layer can attain high wear, weakness or corrosion resistance while the mass material can at present keep its unique properties (Brown & Arnold, 2010). The components required in the most widely recognized laser surface treatments are depicted in appendix A. The main phase of all laser treatments is the ingestion of laser radiation in the substrate (Hildebranda, et al., 2011). Absorption takes place in a thin surface layer, where the optical laser energy is changed over to heat. The retained heat diffuses into the encompassing mass material by conduction (Mazhukin, et al., 1996). The impacts of laser remelting and laser change solidifying depend on microstructural changes of the surface layer (Kim, 2004). Notwithstanding, if the base material can't be enhanced adequately, it can be important, or less expensive, to apply a layer with an alternate organization on top of the base material (Grum, 2007). Three laser methods that can upgrade surface properties by changing the material organization in the surface as follows: laser alloying, laser surface alteration and laser cladding (Naumov, et al., 2015) (see appendix A). Each of this three strategies include the development of a liquid pool to which material is connected. The beneficial outcomes of laser surface treatments depend on a change of the microstructure of the material piece of the surface layer because of a heat cycle which is actuated by a moving laser source (Kim, 2004). The treated area is heated by assimilation of energy conveyed by the laser pillar. Since the heat source is a high-power laser beam, it is well confined given its energy intensity (Arrizubietaa, et al., 2015). Thus, heating rates in the surface layer are high. The warmed layer is self-extinguished, after the laser beam is removed, by dissemination of the heat to the chilly mass. The high warming and cooling rates in the surface layer result in grain refinement and in the development of metastable stages or potentially microstructures (Mustafa, 2013). For those seeking engineering dissertation help, getting closer to the knowledge and process of laser surface treatments. It is critical for exploring advanced materials in engineering techniques.

Background Information

Along these lines, to accomplish a worthy temperature dispersion, the heat contribution by the laser source must be exceptionally all around controlled (Majumdar & Xia, 2007). The laser shaft can be considered as a moving heat source with a specific power thickness appropriation that forces a limit condition on the substrate surface. The established way to deal with demonstrating the heat stream instigated by a disseminated heat source moving over the surface of semi-unbounded strong begins with the arrangement of the heat dispersion condition to decide a point source (Zeng, et al., 2012). Reasonable impacts, for example, temperature-subordinate material properties and radiative and convective limit conditions, on the work piece surface must also be taken into consideration. Likewise, the well-regarded point and line source varieties, nearer approximations to the heat inputs, including Gaussian and more perplexing profiles, have been analysed. Large portions of these endeavours have been abridged by Labudovic et al. (2000). A three-dimensional model of the laser surface alteration procedures is not presently accessible. As Majumdar (2007) clearly demonstrates, a more straightforward recreation, which accommodates liquid pool convection just experimentally, might be sufficient for some mechanization applications requiring ongoing procedure checking and control. Mechanized frameworks are right now being investigated for laser handling of a few materials (e.g. high-quality, low-combination steels). The vision framework is utilized as a part of laser preparing for process checking and for distinguishing any deviations from perfect conditions because of different peculiarities (Zhang & Chou, 2006). Constant process adjustment might be given by contrasting the deliberate flag and that anticipated by a model. While constrained analyses on crinkle following resulting from cooling rate control utilizing surface temperature detecting have been accounted for no broad numerical models seem to have been created to supplement these trials. This paper shows another three-dimensional model of the laser surface change process while utilising the procedures of finite element capabilities of the ANSYS parametric design language (APDL). The results will be compared to results obtained by researchers in peer-reviewed and accepted journal articles.

Engineering Context

The most principal technique for checking the execution of a laser is to gauge its energy or energy yield (Kim, 2004). Laser yield specifically influences a laser's capacity to play out a procedure. Measuring and observing this parameter is vital from the time a laser is initially produced, through framework combination, and on to the last end client. It has wide application particularly in scientific mechanical applications (Zhang & Chou, 2006). These sorts of estimation frameworks for the most part include two bits of gear that are frequently sold independently: First is a sensor that is set into the laser beam and gives a signal yield relative to the laser input (Yu, 2005). The second part is the meter, which is a display and analysis device which interprets the signal from the sensor by applying different simple and advanced amendments, (for example, making up for the distinction between the alignment wavelength and the wavelength of the laser), and afterward give an estimation (Zamfir, 2009). A few meters give an estimation that are displayed automatically while others give more modern information examination and PC interfacing may be required (Grum, 2007).

The pulse length of a laser regularly alludes to the yield of a pulsed laser and is identified with the power yield, where the energy (E) is the laser's peak power (PPEAK) multiplied by laser pulse duration (t). The pulse length can be short (i.e. picoseconds or femtoseconds) bringing about high peak powers with moderately low pulse energy, or can be long (i.e. milliseconds) bringing about low peak power and high pulse energy (Mazhukin, et al., 1996). Each of these conditions may have comparable normal power levels.

Continue your exploration of Cinema Verite and Direct Cinema with our related content.

Generation of a laser beam is a 3-step process that occurs instantaneously as follows: The pump source gives energy to the medium, energizing the laser medium atoms to such an extent that electrons held within the molecules are raised incidentally to higher energy states (Adel, et al., 2009). The electrons held in this energized state can't stay there uncertainly and drop down to a lower energy level. In this procedure, the electron loses the overabundance energy picked up from the pump energy by releasing a photon (Grum, 2007). This is called spontaneous discharge and the photons created by this technique kick-start the process. The photons discharged by spontaneous outflow in the end strike different electrons in the higher energy states. In the long run a brief span is created because of the speed of light and thickness of energized molecules (Mustafa, 2013). The approaching photon knocks the electron from the energized state to a lower energy level making another photon. These two photons are plain significance they are in stage, of a similar wavelength, and travelling in same direction which is called stimulated emission (Kim, 2004).

The photons are discharged in all directions. However, some go along the laser medium to strike the resonator mirrors to be reflected back through the medium. The resonator mirrors define preferential amplification for stimulated discharge. For amplification to occur, there must be greater percentage of atoms in the excited state as compared to the percentage in lower energy levels. This "population reversal" or inversion characterised by more particles in the energized state prompts to the conditions required for laser generation.

Physical Model and Simulation Description

There are two of types of Nd:YAG laser welders; continuous wave and pulsed. As the name proposes, continuous wave or CW is either on or off, while pulsed lasers make welds by individual pulses (Hildebranda, et al., 2011). The pulsed laser uses high peak energy to make the weld, while the CW laser utilizes normal power. This permits the pulsed laser to utilize less energy to make the weld, with a littler heat influenced zone (Teixidor, et al., 2015). This makes the pulsed laser the unrivalled spot welding technique with minimal heat input in seam welding (Zeng, et al., 2012).

Theoretical Framework

Physical description of the model

The laser shaft is placed at an angle (to the surface of the H13 tool steel and titanium alloy, thence referred to as work piece, with a specific end goal to keep back-reflections from the work piece) (Labudovic, et al., 2000).

The work piece is at first at 298 K. Both the work piece and the coordinate mesh are fixed and the beam moves in the positive course with a steady speed,‘t’. The transverse electromagnetic mode (TEM) of the beam is dismissed and disentangled to uniform one, in spite of the fact that the laser shaft can be TËM00, TEM01, TEM11 and TEM,0 or their mixes.

All thermo physical properties are considered dependent on temperature. The inert or latent heat of fusion is simulated through an artificial increase in liquid specific heat. The relationship between the enthalpy, specific heat and density is as follows:

H= ∫pc(T)dt (1)

The absorption of the Nd: YAG laser light by the metals is assumed to be at least 30 percent (Qi, et al., 2006). Since laser surface change includes extremely quick liquefaction and solidifying, convective redistribution of heat inside the liquid pool is insignificant (it is in different procedures where a fluid pool is permanent). Convective stream of heat is therefore disregarded.

There is no keyhole formation since laser is defocused and for this reason, energy absorption by the plasma can be neglected.

Mathematical Description

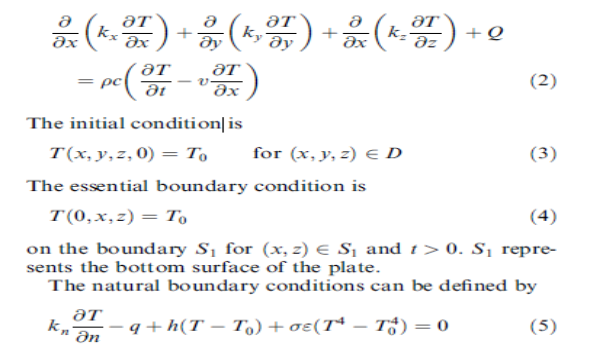

The temporary temperature distribution T(x, y, z, and t) must satisfy the following differential equation for 3D heat conduction

In the above equations, the inclusion radiation term and temperature-dependent thermo physical properties renders this analysis non-linear given that radiation effects have been found to increase in a solution by as much as three times (Rao, et al., 2014). Brown and Arnold (2010) equation for experimental relationship for laser welding of hot-rolled titanium and steel is

H = 2.4 x 10-3ET1.61

Numerical Description

ANSYS is a convenient approach in numerical modelling of laser surface modification process. As such, it requires integration of heat conduction equation presented above with respect to time. The equation is as follows:

CT T+[KTT+V={QT} (Labudovic, et al., 2000)

The heat boundary conditions at different times and positions can be obtained with the above formula.

The moving laser beam is simulated using ANSYS parametric design language (APDL) to provide the heat boundary conditions at different positions at different times.

The first iteration in the solution procedure solves the system equations at an assumed starting temperature (298 K) and subsequent iterations use temperatures from previous iterations to calculate thermal conductivity and specific heat matrices (Grum, 2007). The iterative process continues for time T until a converged solution is achieved or until the dynamic equilibrium of heat exchanging is established (Brown & Arnold, 2010). Various research findings have shown that the geometric shape of the molten pool will be in steady state after 2 s (Majumdar & Xia, 2007; Arrizubietaa, et al., 2015; Labudovic, et al., 2000). Therefore, T = 2 s is used as the time T once dynamic equilibrium has been established for the heat exchanging.

The solution data are in the form of nodal temperatures and heat flows. The results can be post processed by a time history post-processor and displayed in graphical or tabular form.

Research Objectives

Defining the different laser parameter for laser both pulse and continuous laser.

Investigating and expanding the knowledge of different equation and boundary conditions that will be related to heat transfer that occurs during the simulation.

Conduct a parametric study of thermal modelling on a 3D model using the defined parameter in ANSYS (Selecting the material to be H13 tool steel and titanium alloy)

Comparing and reviewing the result between the materials and reviewing it to find ways for optimisation of process parameter for laser surface glazing.

Chapter 2: Literature Review

According to Mustafa (2013), the laser pole utilized as a part of Nd:YAG laser welders and markers is an engineered gem of Yttrium Aluminum Garnet. The YAG material is the "host" material that contains a little portion of neodymium, the dynamic component. The substitution of the yttrium particles with neodymium particles is called doping, and normally the doping rate is around 1 – 1.5% (Kim, 2004). The doping level is chosen to upgrade the lasing impact and counteract over the top strain on the gem, as the Nd3+ particle is physically bigger than the Y3+ particle (Mazhukin, et al., 1996). The YAG precious stone is a perfect host for the lasing material Nd3+, being physically hard, stable, optically isotropic, and has great heat conductivity that allow laser operation at high normal power levels (Hildebranda, et al., 2011). Neodymium is a good lasing material as it creates the most abnormal amount of forces than whatever other doping component (Yu, 2005). The measurements of the laser poles are chosen for power and optical quality, with the greatest bar estimate restricted to around 15mm width and 200mm long for reasons of gem quality and heat administration (Qi, et al., 2006).

According to Naumov et al. (2015), Change of surface properties over different length scales plays an essential part in upgrading a material's execution for a given application. For example, the restorative appearance of a surface and its absorption properties can be controlled by adjusting its surface and nearness of compound polluting influences in the surface (Kim, 2004). A material's weakness to wear and surface harm can be lessened by changing its surface science, morphology, and gem structure [4]. Likewise, one can consider the frictional, glue, and wetting strengths acting at a material interface as being forcefully impacted by the size and state of the smaller scale and nano scale elements introduced (Brown & Arnold, 2010). In that capacity, multi-scale surface modifications are basic considerations in the improvement of new material structures and in designing the point by point connections that happen at surfaces and interfaces (Zeng, et al., 2012). From the most punctual work with pulse ruby lasers, it has been understood that the one of a kind association of laser light with a material can prompt to lasting changes in the materials’ properties which is difficult to achieve using means (Rao, et al., 2014). Laser light is used in laser ablation which entails removal of material from a substrate by direct absorption of laser energy. Laser ablation is generally examined with regards to pulse lasers; in any case, it is likewise conceivable with extreme CW illumination. The onset of ablation happens over an edge influence, which relies on upon the absorption system, specific material properties, microstructure, morphology, the nearness of deformities. Additionally, on laser parameters, for example, wavelength and pulse rate (Hildebranda, et al., 2011). With various pulses, the ablation edges may diminish because of gathering of imperfections. Above the ablation edge, thickness or volume of material displaced per pulse ordinarily demonstrates a logarithmic increment with fluence as indicated by the Beer–Lambert law (Qi, et al., 2006). An assortment of systems for material removal might be dynamic amid laser ablation depending upon the specific material framework and laser preparing parameters such as wavelength, fluence, and pulse length [40]. At low fluences, photo thermal systems for ablation incorporate material dissipation and sublimation (Zamfir, 2009). For multicomponent frameworks, the more unstable species might be drained all the more quickly.

According to (Labudovic, et al., 2000), if material heating is adequately quick for the material to approach its thermodynamic critical temperature, fast homogenous nucleation and development of vapour air pockets prompt dangerous bubbling (phase explosion) that carries away solid and liquid fragments. These thermal mechanisms can be comprehended as thermodynamic stage changes in light of the high temperatures (Grum, 2007). At the point when the excitation time is shorter than the thermalization time in the material, non-thermal, photochemical ablation components can happen. For example, with ultrafast pulses, direct ionization and the arrangement of thick electron-gap plasmas can prompt a thermal stage changes, coordinate bond-breaking, and dangerous breaking down of the grid through electronic repugnance (Coulomb blast) (Labudovic, et al., 2000). In specific non-metals, for example, polymers and organic materials with generally long thermalization times, photochemical ablation can at present happen with short wavelength nanosecond lasers, delivering all around characterized removed locales with little HAZs (Kim, 2004). The thick vapour crest may contain strong and fluid bunches of material. At high forces, a huge division of the species may get to be ionized, creating a plasma. Additionally, with pulses longer than ps, interaction of laser light with the plume might be noteworthy. The plume can ingest and disseminate radiation, changing the real flux got by the surface. Recoil from the plume can create shockwaves in the material, bringing about plastic twisting and work solidifying (Kim, 2004). The laser's transitory pulse length can significantly affect the elements of the ablation procedure. As a rule, as the pulse length is abbreviated, energy is more quickly stored into the material prompting to a more fast material launch (Labudovic, et al., 2000). The volume of material that is specifically energized by the laser has less time to exchange energy to the encompassing material before being launched out. In this manner, the removed volume turns out to be all the more decisively characterized by the laser's spatial profile and optical entrance profundity, and the staying material has less leftover energy (Grum, 2007).

According to Qi et al. (2006) Laser surface melting (LSM) can likewise be utilized to fuse new material into an existing surface. In laser cladding and hard facing, new material is blown powder and reinforced or fed in by wire feedstock ideally while eliminating dilution to a basic substrate to make another surface with practically no porosity and improved imperviousness to wear, high temperature, and destructive situations (Teixidor, et al., 2015) .It gives coatings with a more reliable thickness, better surface complete, littler HAZs, less breaking, and lessened part mutilation than conventional heat showering and welding strategies. With higher laser control, finish blending of the new material into the liquid surface can shape a homogenously alloyed layer. Quick resolidification guarantees negligible isolation, permitting numerous materials to be alloyed according to their common solvency (Hildebranda, et al., 2011). Materials can be alloyed to expand their hardness. What's more, consumption resistance or decrease grating wear properties of the part surface. Laser cleaning uses exceptional laser radiation to specifically evacuate contaminants from a strong surface while leaving the fundamental substrate to a great extent unaffected. The method contrasts with the optical and heat properties of the basic substrate and the contaminant layer and the capacity for absolutely control is enhanced (Grum, 2007).

Method

This interim dissertation adapted Labudovic et al. (2000) methodology for simulation and modelling.

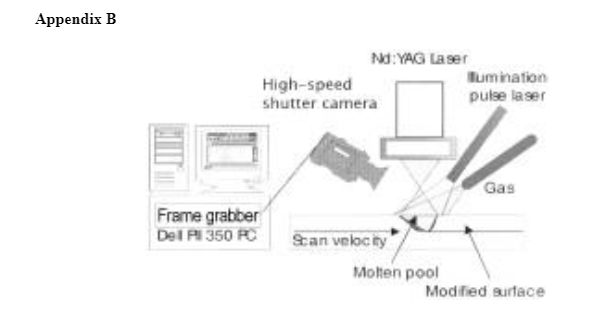

The exploratory set-up comprised of a Nd:YAG laser, two-hub CNC situating framework, laser strobe vision framework, protecting gas and H13 steel and titanium alloy mentioned earlier The arrangement is demonstrated in appendix B. Fiber optics leads a laser light of wavelength 337 nm to enlighten the Nd:YAG laser treating area. The lighting up laser is a nitrogen pulse laser with 5 ns pulse length synchronizing with the fast screen of the camera. The camera of the laser strobe vision framework is furnished with a bright (Uy) channel that exclusive permits light of around 337 nm wavelength to pass.

Amid the brightening time frame, the force of the enlightening laser can smother the splash and plasma light (Labudovic, et al., 2000). What's more, because of the impression of the mirror-like liquid pool an all-around differentiated picture of the liquid pool can be acquired. Nitrogen is utilized as an alloying gas and as a protecting gas. A casing grabber introduced on a P11 350 PC procures pictures from the ultra-high shade speed camera at 30 Hz. Continuous picture preparing and acknowledgment, and in addition liquid profundity estimation and shut circle control, will be finished on a similar PC.

Results

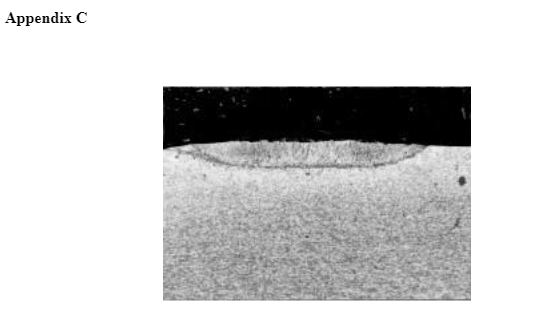

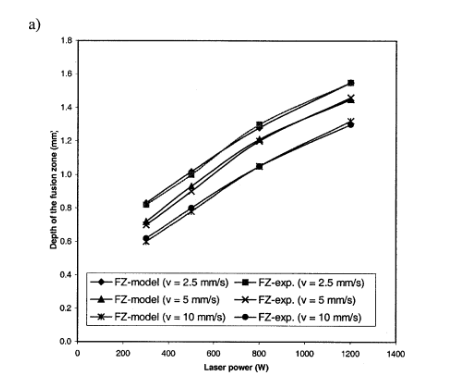

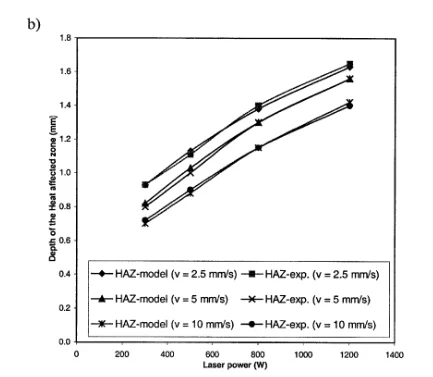

Correlation of examination and reproduction was done by type AIS! 1006 steel plate. The limited component work is appeared in because of symmetry about the z' plane, just 50% of the plate is considered. The model was kept running for both compounds with laser heating and for the ensuing cooling time frame utilizing diverse forces (in the range 300—1200W), and checking speeds (in the range 2.5—10 mrn/s).The information produced amid the arrangement strategy incorporates profundity of the I 540 and 730 Le isotherms that around speak to the combination zone (FZ) and heat-affected zone (HAZ) limits, individually. This information was then contrasted through trial and error. Appendix C and D demonstrate micrographs of the cross-segments of two adjusted surfaces (laser control 300 W and checking velocities of 5 and 2.5 mm/s individually). The depth and width of the FZ and HAZ might be measured from these micrographs. Similarly, as this laser-changed surface was physically segmented, an area through the centreline of the model can likewise be taken. ANSYS display forecasts of the FZ and HAZ are superimposed on these smaller scale charts. These isotherms speak to the positions that have been warmed to a most extreme temperature of 1540 and 730 C separately. The model was additionally kept running for the other laser powers and examining speeds. The temperature of each nodal point inside the strong was computed as a component of time. The greatest depth and width of the 1540 and 730 C temperature forms were measured for every laser power and examining speed. These estimations have been plotted in appendix D and might be contrasted specifically and the test estimations of the FZ and HAZ measurements separately.

Discussion

Pictures of the liquid pool acquired by laser strobe vision framework indicate a very good agreement with those obtained online. The size and state of the liquid pool images acquired on-line is practically the same as those got by re-enactment for all connected laser powers and filtering speeds. Moreover, by watching the liquid pool it can be seen that the pool is more profound toward the end than at the front in view of the amassing of heat (see appendix C and D). However, an expansion of the laser power and diminishing of the examining speed brought about a more extensive liquid pool. Temperature designs permit assessment of the depth of the liquid pool which is the significant issue of the late pattern towards surface change automation.

Conclusion

The 3D finite model of heat flow simulation during laser surface ablation illustrates a good agreement with experimental results. A comparison of depths of HAZ and FZ shows perfect semblance with those obtained from actual physical sectioning of specimens through metallographic experiments (see appendix E).

Recommendations

Since there are no reliable sensors presently available for the remote, real time measurement of absolute molten pool temperature, the obtained results can be used for molten pool depth estimation and closed-loop control of the laser surface modification. The real-time control of the process. In order to produce more stable and repeatable molten pool depth and adaptation of the model to a more complex shape of the processed parts will be a challenge in subsequent research.

References

- Adel, M., Dhia, S. & Ghazali, J., 2009. The effect of laser surface hardening on the wear and friction characteristics of acicular bainitic ductile iron. International Journal of Mechanical and Materials Engineering , 4(2), pp. 167-171.

- Arrizubietaa, I. et al., 2015. Thermal simulation of laser-assisted turning. Procedia Engineering, Volume 132, pp. 639-646.

- Brown, S. & Arnold, B., 2010. Fundamentals of laser-material interaction and application to multiscale surface modification. Laser Precision Microfabrication, Volume 135, pp. 91-120.

- Grum, J., 2007. Comparison of different techniques of laser surface hardening. Journal of Achievement in Materials and Manufacturing Engineering, 24(1), pp. 17-25.

- Hildebranda, J., Hechtb, K., Bliedtnerb, J. & Müller, H., 2011. Laser eam polishing of quartz glass surfaces. Physics Procedia, Volume 12, pp. 452-461.

- Kim, J., 2004. Transient evaporative laser cutting with moving laser by boundary element method. Applied Mathematical Modelling, Volume 28, pp. 891-910.

- Labudovic, M., Hu, D. & Kovacevic, R., 2000. Three-dimensional finite element modelling of laser surface modification. Procedia Institutional Mechanical Engineering, Volume 214, pp. 684-694.

- Majumdar, P. & Xia, H., 2007. A Green’s function model for the analysis of laser heating of materials. Applied Mathematical Modelling, Volume 31, p. 1186–1200.

- Mazhukin, V., Smurov, I. & Flamant, G., 1996. 2D-simulation of the system: laser beam + laser plasma + target. Applied Surface Science, Volume 96-98, pp. 89-96.

- Mustafa, H., 2013. Thermal simulation of laser surface processing for hot forming die surface hardening. s.l.:s.n.

- Naumov, A., Kondratenko, V., Borisovskiy, V. & Zobov, A., 2015. Optimizing the parameters of laser controlled thermocracking when cutting glass by a non-rectilinear contour. Optics and Photonics Journal, Volume 5, pp. 296-303.

- Qi, H., Mazumder, J. & Ki, H., 2006. Numerical simulation of heat transfer and fluid flow in coaxial laser cladding process for direct metal deposition. Journal of Applied Physics, Volume 100, pp. 100-110.

- Rafique, A. & Musaddique, M., 2013. Modeling and simulation of heat transfer phenomena. Boston: Intech.

- Rao, U., Vasu, V., Shariff, M. & Srinadh, S., 2014. Improvement of corrosion resistance by laser surface melting of 7075 aluminum alloy. 5th International & 26th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014) December 12th–14th, 2014, IIT Guwahati, Assam, India, Volume 1.

- Teixidor, D., Ferrer, I., Ciurana, J. & Ozel, T., 2015. Optimization of process parameters for pulsed laser milling of micro-channels on AISI H13tool steel. Robotics and Computer-Integrated Manufacturing, 48(5), pp. 1-10.

- Yu, N., 2005. Process parameters optimisation for direct metal laser sintering (DMLS). s.l.:s.n.

- Zamfir, I., 2009. The influence of the laser surface mekting parameters (LSM) on the structure and microhardness of the 316L Austenitic stainless steel. U.P.B. Sci. Bull, 71(3), pp. 138-148.

- Zeng, K., Pal, D. & Stucker, B., 2012. A review of thermal analysis methods in laser sintering and selective laser melting. Louisville: University of Louisville.

- Zhang, Y. & Chou, K., 2006. A parametric study of part distortions in FDM using 3D FEA. Tuscaloosa: The University of Alabama Press.

Appendices

Appendix E

Take a deeper dive into The Impact of Talent Management on Organizational Performance with our additional resources.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts