Phase Transformation Study in Titanium Alloy

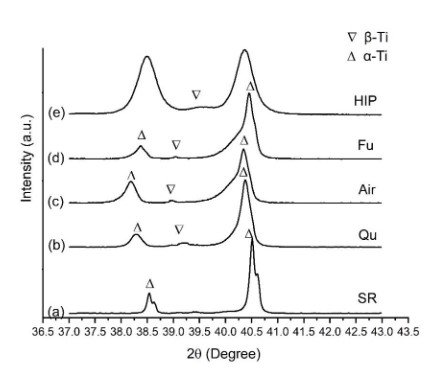

Different heat treatment temperatures and cooling rates could control the specific phase to be formed. However, the β-Ti phase is hardly detected, even after 704 °C in accordance with those XRD patterns highlighted in Figure 5, where the initial microstructure is composed of α-Ti phase with no other phase being noted in the XRD pattern. The peaks were defined by α-Ti since both α and α′ phases have a hexagonal structure with XRD peaks in similar angular positions, where the amount of solute elements in the atomic structure is basically the metallurgical difference between α and α′ (22). This finding supports the one presented by both Ter Haar (2018) and Kelly et al. (2004), where they found out that the α phase started to dissolute into the β phase under equilibrium heating conditions at 707.8 °C and 705 °C respectively (23)(24). Besides, Malinov et al. (2002) found out that the beta phase nucleation starts from 650 °C to become around 4% at 700 °C, which is difficult to be observed, while it is about 10% at 750 °C (25). However, on the one hand, in the presence of any β phase, the amount would be very low and it would be barely detected, particularly, XRD has a detection limit of about ~ 2% of the sample (26). On the other hand, the microstructure of the air and furnace cooled is composed of both α and β phase. Compared to air-cooling, the XRD peak of the β phase intensity is weaker after furnace cooling owing to the low volume fraction of β phase in the alloy at room temperature. Compared to air and furnace cooling, the peak intensity of β in quenched samples is higher than the others. This might be attributed to the rapid cooling process from 1015 °C (100% β phase), which results in diffusionless transformations; hence, there is inadequate time for alpha to form. This results in the formation of the dominating α′ martensite phase allowing an additional amount of β that remains between the needles as compared to the air-cooling process. For those seeking education dissertation help, this phenomenon highlights the complexity and importance of precise temperature control in metallurgical processes.

Figure 5. XRD patterns of SLM samples after different heat treatments; (a) Stress relived, (b) quenched, (c) air-cooled, (d) furnace cooled and (e) HIPed samples.

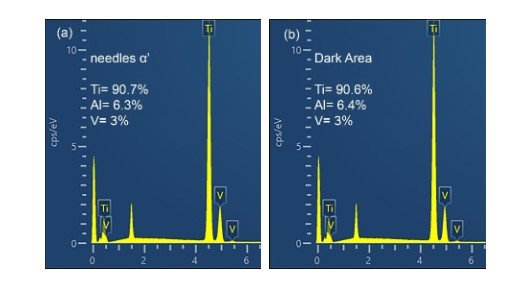

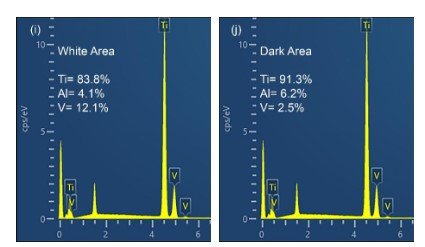

Figure 6. EDS spectrum and the composition in wt. % of Ti-6Al-4V samples after different heat treatment; (a and b) SR at 704 °C, (c and d) WQ from 1015 °C, (e and f) AC from 1015 °C, (g and h) FC from 1015 °C and (I and j) SR+HIP followed by FC.

Looking for further insights on Personal social and emotional development? Click here.

Conclusion

The primary objective of the current study was to analyse the microstructure properties of the Ti-6Al-4V alloy fabricated by SLM after it underwent diverse heat treatment levels. The main conclusions that can be drawn from the conducted research are:

There was no significant difference in hardness or microstructure between the top and bottom of each sample before post-heat treatment.

Only the α′ martensitic phase can be detected even at 704 °C, whereas noticeable changes with further treatment at 1015 °C followed by different cooling rates occurred, whereas slow cooling (furnace) led to a coarse lamellar microstructure of α+β, and air-cooling led to a mixture of α'+α with lower hardness, and therefore, more ductility compared with those SR samples.

The sample that failed in fatigue had cracks and increased porosity on the fracture surface compared to the other samples, which led to it failing prematurely during fatigue testing, and needs further investigation.

Furnace and HIP processed samples have lower microhardness, hence, better mechanical properties. This can be explained by the transformation of the needle-shaped α' to lamellar α+β and the appearance of a more ductile β phase.

Looking for further insights on Personal social and emotional development? Click here.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts