monitoring the machine conditions

Introduction

Technology has introduced better means of handling processes or even managing conditions. One of such technologies includes machine learning as well as artificial intelligence, which are said to have bolstered a wide range of processes and things. Among these processes and things is equipment maintenance. In the contemporary industrial context, discussion on machine learning points at predictive maintenance enabled through machine learning algorithms known for preventing a range of anomalies and losses at the same time. The observations on machine learning and predictive maintenance have attracted a number of discussions. According to Lee et al. (2019), the industrial context narrows down to the manufacturing equipment which is largely used without necessarily having a planned maintenance approach. This would commonly result into unplanned downtown, which can also initiate failures in the system. Lee et al. (2019) further insisted that subsequent focus on scheduled maintenance can enable industrial players to avoid any unexpected equipment stoppages or failures. For students seeking expertise in this area, especially in the context of industrial applications, seeking data analysis dissertation help can provide valuable insights and support.

The significant rise of smart systems as well as industry 4.0 has imminently led to increased attention towards predictive maintenance strategies, which are believed to have the capacity of reducing the costs involved in downtime. The strategies are also believed to have the capacity of ensuring availability of the manufacturing or production equipment thereby ensuring a consistent flow of the process. Lisowski (2019) also noted that there are number of approaches engaged to address predictive maintenance. The most popular ones include vibration analysis, which is regarded as technique applied in detecting looseness, imbalance and wear among other defects. Another approach is the infrared thermography analysis in which sensors are involved in monitoring the temperature of the equipment thereby avoiding chances of overheating. Other approaches include current analysis and vibration analysis. Apparently, system developers are never satisfied with the kind of problems that need to be addressed through the significant use of technology. This means that service provided by machine learning may not be enough. Perhaps, there also a significant consideration of Internet of Things and application of sensors while collecting as well as sharing data. Apparently, the link between the available assets and central hub is what best describes the scope of predictive maintenance. In as much as studies have provided insights into what machine learning can do in terms of predictive maintenance, there is still a research gap in terms of the direct application of machine learning without necessarily involving other technologies.

Research Problem

Within the industrial context, most of the studies generally talk about how neural networks, artificial intelligence and machine learning have transformed the way of doing things. The application narrows down to predictive maintenance with attempts of reducing case scenarios of downtime and failures in the course of production or maintenance. The studies have also discovered that machine learning is more convenient when applied along Internet of Things. However, among all studies, none of them has shown the detailed insights of data gathering methodologies under machine learning that have led to the evident transformations in the industries. Again, none of them has directly touched on machine learning as an independent tool that has led to such changes in the industry.

Research aim and Objectives

The main aim of this research is to establish the use of machine learning in reducing preventive maintenance of equipment through monitoring machine conditions. The supporting objectives include

To establish the key role of machine learning in predictive maintenance

To highlight the influence of machine learning in sparing costs in the production and manufacturing process

To establish means through which machine learning can reduce maintenance activities

Literature Review

The paramount study of machine learning has attracted insights which are believed to have been covered in the prior studies. The research is more concerned with what is being provided in other studies in relation to machine learning as an imminent technology in the modern world. According to Cho et al. (2018) argued that advanced technologies known to be based on Internet of Things are introducing a trail of the most efficient and effective management of all the times as far as manufacturing companies are put into consideration. At the centre of machine learning, system developers are focusing on the hybrid element which fosters the predictive maintenance pilot. Cho et al. (2018) further noted that due to machine learning, industries have witnessed scalable digitization, digital transformation and significant application of industry 4.0. The most significant element revolves around connectivity as well as flow of information across the sensors and devices. For years now, industries have been forced to compensate for tremendous losses as a result of breakdowns and failure. The outcry has prompted research in anomaly detection, an idea that was floated through the knowledge of machine learning. Notably, anomalous data cannot be delinked from malicious activities which may result into malfunctioning of equipment, structural defects, bank fraud and even medical problems among others. Then, the question is how is it possible to determine whether data is anomalous or normal? Machine learning shares insights to possible panaceas to detection problems when it comes to industrial operations. This can first be learned through research done on the following areas.

2.1 Role of machine learning in predictive maintenance and anomalous detection

2.2 Data gathering methodologies for machine learning in industries

2.3 Influence of machine learning in sparing costs in the production and manufacturing process

2.4 Ways through which machine learning can reduce maintenance activities

Methodology

The research will heavily rely on mixed methods for description of research tools used in the research process. Mixed methods borrow from qualitative and quantitative research methods, which offer both the statistical and descriptive value. Both primary and secondary shall be used in this context. Stakeholders would be interviewed on how machine learning has been beneficial while model comparison would essentially tap into the systematic literature review.

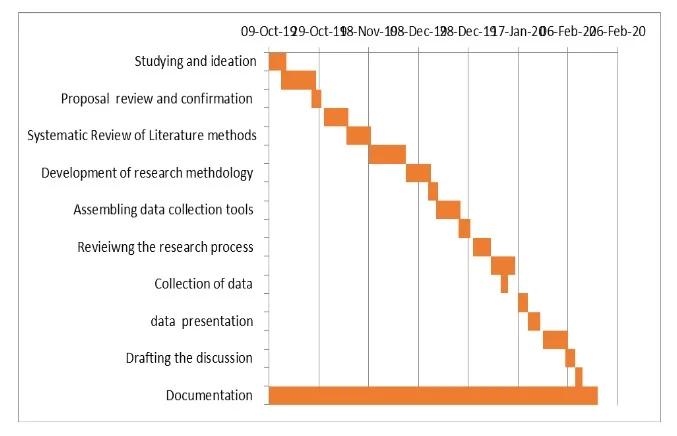

Timescale

References

Cho, S., May, G., Tourkogiorgis, I., Perez, R., Lazaro, O., de la Maza, B. and Kiritsis, D., 2018, August. A Hybrid Machine Learning Approach for Predictive Maintenance in Smart Factories of the Future. In IFIP International Conference on Advances in Production Management Systems (pp. 311-317). Springer, Cham.

Lee, W.J., Wu, H., Yun, H., Kim, H., Jun, M.B. and Sutheralnd, J.W., 2019. Predictive Maintenance of Machine Tool Systems Using Artificial Intelligence Techniques Applied to Machine Condition Data. Procedia CIRP, 80, pp.506-511.

Lisowski, E. 2019. Predictive Maintenance and Prevention using Machine Learning. Available at

Continue your journey with our comprehensive guide to Minority Youth Justice System Evaluation.

- 24/7 Customer Support

- 100% Customer Satisfaction

- No Privacy Violation

- Quick Services

- Subject Experts